CPP film with high interfacial bonding strength

A technology of interfacial bonding strength and polymer, applied in the direction of surface pretreatment, synthetic resin layered products, and devices for coating liquid on the surface, etc., can solve the problems of obvious degradation effect and low surface tension of CPP corona treatment film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

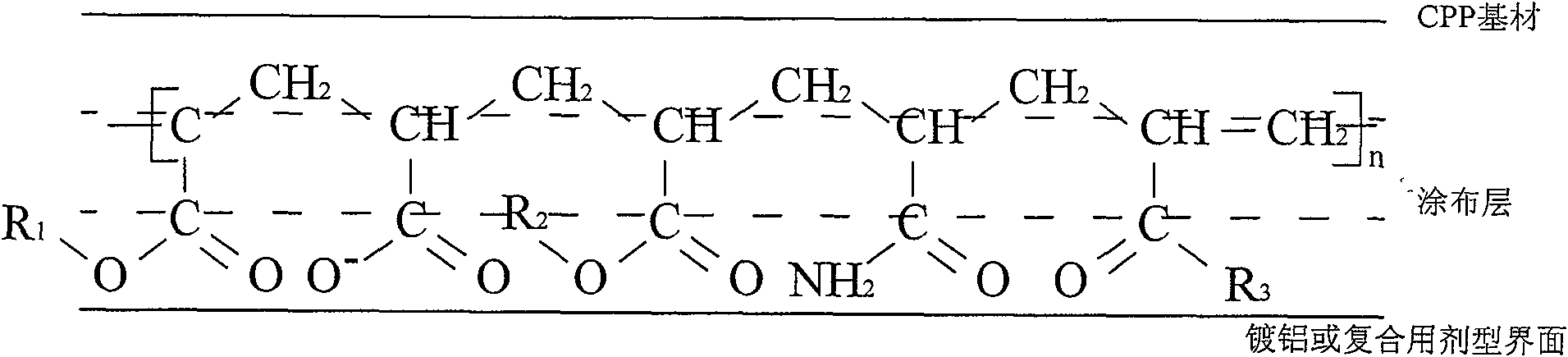

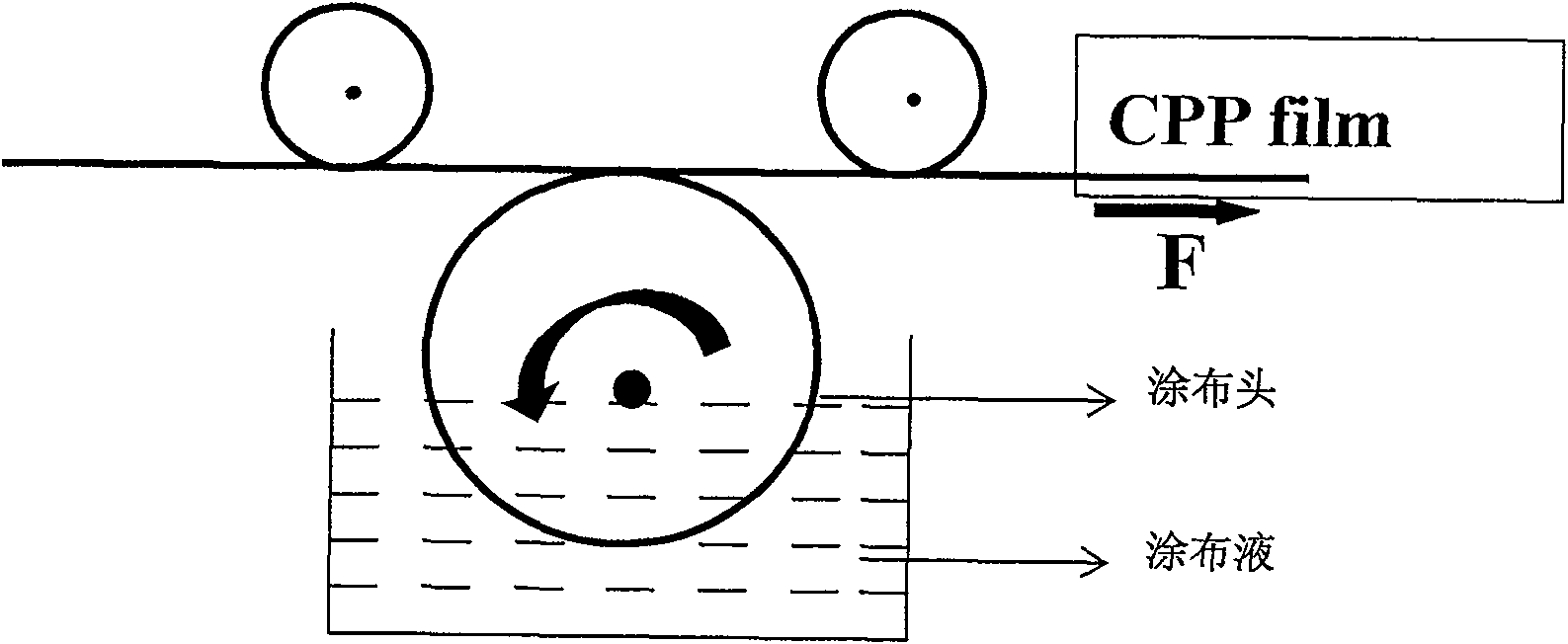

[0023] High interfacial bonding strength CPP film is made by surface coating method, including CPP substrate layer and coating layer. The coating layer is a polymer microemulsion. The preparation process is as follows:

[0024] A. Equipped with a temperature controller, N 2 Add 1-3% emulsifier and 97-99% water into the reaction kettle of the introduction pipe, agitator and condenser pipe, and disperse at 65°C;

[0025] B. After the dispersed solution is kept at a constant temperature for 0.5 hours, add a mixed solution containing 0.5-1% emulsifier and 0.2-3% cross-linking functional group monomer and drop it into the reaction kettle. The pH value is maintained at 3-9. After maintaining the temperature for another 1 hour, add an aqueous initiator and raise the temperature to 75° C., and react for 6 hours to prepare a polymer microemulsion.

[0026] The emulsifier contains methyl methacrylate, ethyl acrylate, acrylic acid, hydroxyethyl acrylate, hydroxyethyl methacrylate (in pa...

Embodiment 2

[0031] High interfacial bonding strength CPP film is made by surface coating method, including CPP substrate layer and coating layer. The coating layer is a polymer microemulsion. The preparation process is as follows:

[0032] A. Equipped with a temperature controller, N 2 Add 1-3% emulsifier and 97-99% water into the reaction kettle of the introduction pipe, agitator and condenser pipe, and disperse at 60°C;

[0033] B. After the dispersed solution is kept at a constant temperature for 1 hour, then add a mixed solution containing 0.5-1% emulsifier and 0.2-3% cross-linking functional group monomer and drop it into the reaction kettle. The pH value is maintained at 3-9. After maintaining the temperature for another 1 hour, add an aqueous initiator and raise the temperature to 85° C., and react for 5 hours to prepare a polymer microemulsion.

[0034] The emulsifier contains methyl methacrylate, ethyl acrylate, acrylic acid, hydroxyethyl acrylate, hydroxyethyl methacrylate (in ...

Embodiment 3

[0037] High interfacial bonding strength CPP film is made by surface coating method, including CPP substrate layer and coating layer. The coating layer is a polymer microemulsion. The preparation process is as follows:

[0038] A. Equipped with a temperature controller, N 2 Add 1-3% emulsifier and 97-99% water into the reaction kettle of the introduction pipe, agitator and condenser pipe, and disperse at 45°C;

[0039]B. After the dispersed solution is kept at a constant temperature for 1.5 hours, then add a mixed solution containing 0.5-1% emulsifier and 0.2-3% cross-linking functional group monomer and drop it into the reaction kettle. The pH value is maintained at 3-9. After maintaining the temperature for another 2 hours, add an aqueous initiator and raise the temperature to 90° C., and react for 4.5 hours to prepare a polymer microemulsion.

[0040] The emulsifier contains methyl methacrylate, ethyl acrylate, acrylic acid, hydroxyethyl acrylate, hydroxyethyl methacrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com