Method for preparing antibacterial blending polyester heteromorphic fibre

A special-shaped fiber and blending technology, which is applied in the field of preparation of nanomaterials technology, can solve the problems of limited moisture absorption and perspiration function, single polyester, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

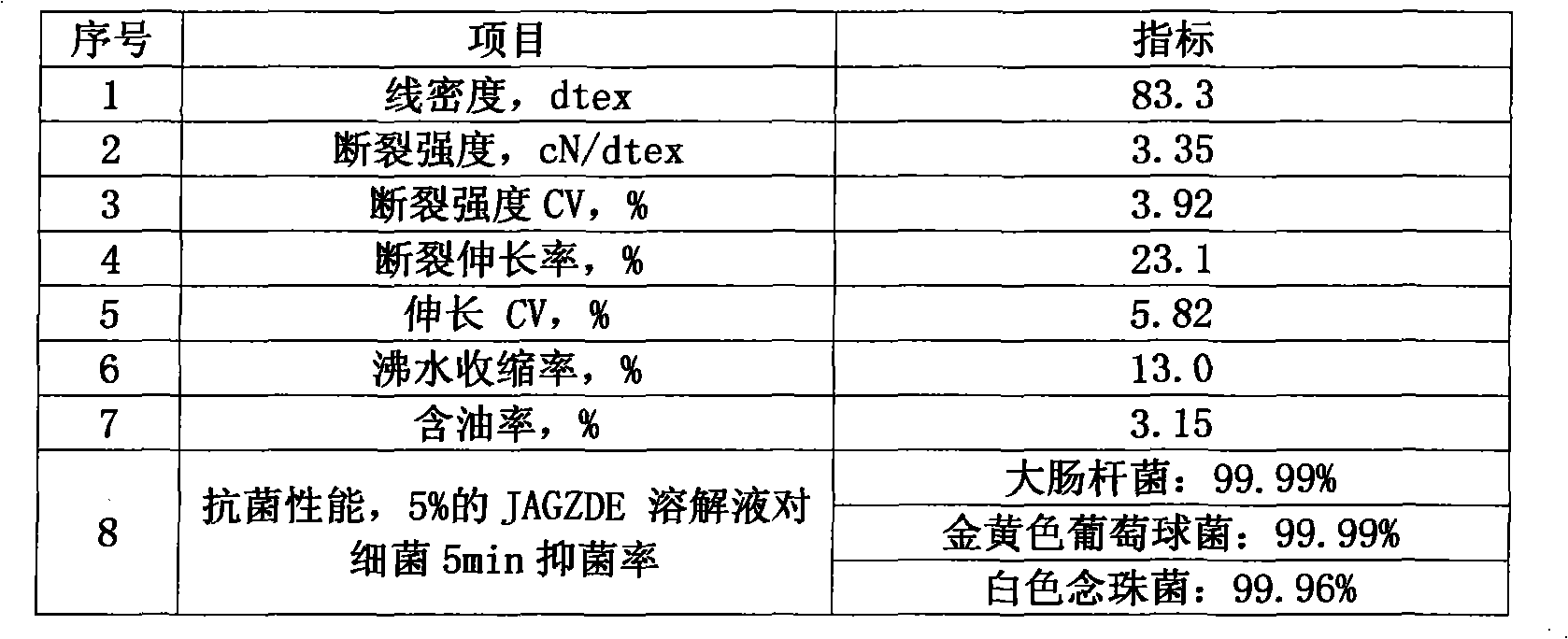

[0029] Take by weighing 0.25g of dried titanium phosphate-loaded silver ion antibacterial agent with a particle size of 30nm and 1.25kg of dried PBT slices to prepare antibacterial PBT masterbatch, and add this antibacterial masterbatch to 30kg of dried In PBT chips, after blending, melting, cross-shaped spinneret is used, and PBT POY fibers are obtained after winding. Store at 25°C for one day at a relative humidity of 65%, and then perform false twist deformation processing to obtain the physical properties of the antibacterial DTY yarn as shown in Table 1 below:

[0030] Table 1 PBT antibacterial silk physical properties index

[0031] Specifications: 83dtex / 72f

[0032]

Embodiment 2

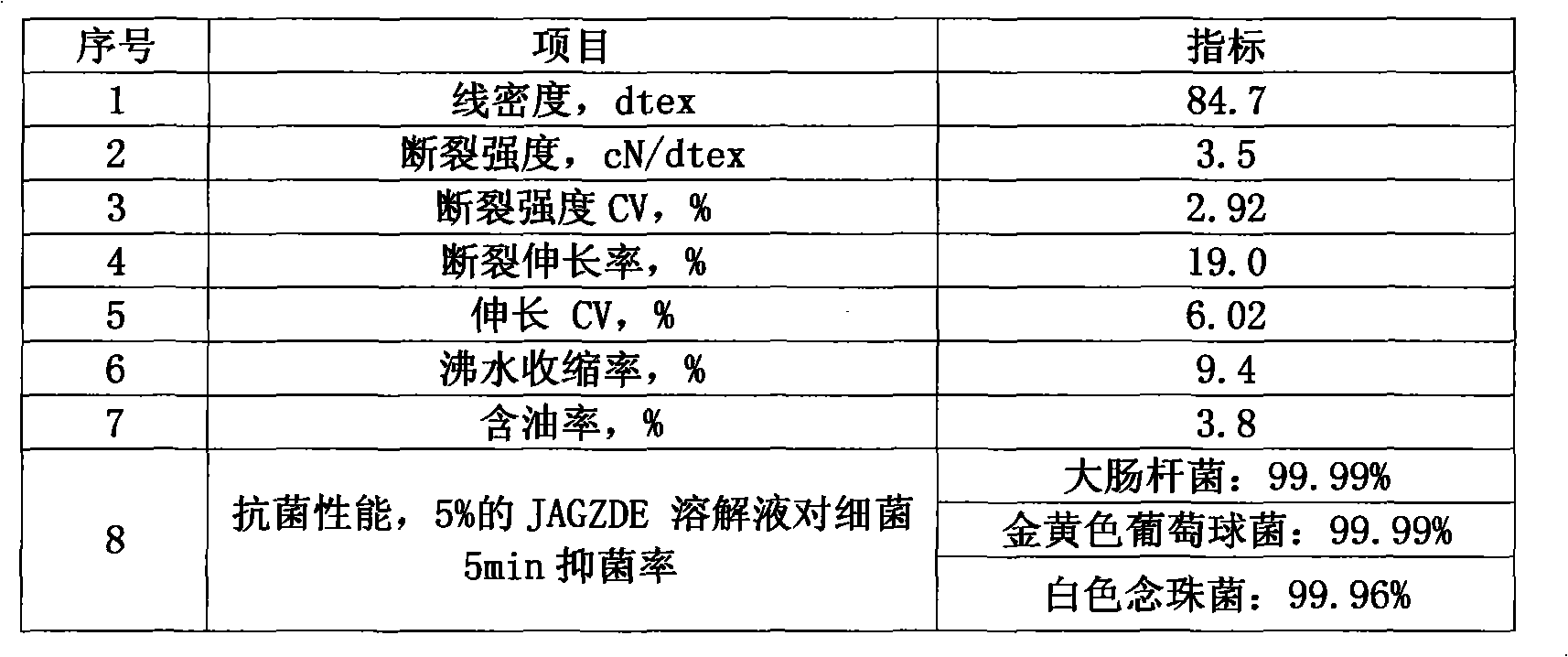

[0034] Weigh 0.25g of silver ion antibacterial agent loaded with titanium phosphate salt with a particle size of 30nm and blend with 1.25kg of dried PET chips to prepare antibacterial PET masterbatch, add this antibacterial masterbatch to 30kg of dried PET / PBT (PET / PBT=75 / 25) slices, after blending, melting, using 13-hole multi-hole spinneret spinneret to spin, and obtaining PET / PBT POY fibers after winding. Under the conditions of 25°C and 65% relative humidity, after storing for one day, false twisting processing was carried out to obtain the physical properties of the antibacterial DTY yarn as shown in Table 2 below:

[0035] Table 2 Physical property index of PET / PBT antibacterial silk

[0036] Specifications: 83dtex / 72f

[0037]

Embodiment 3

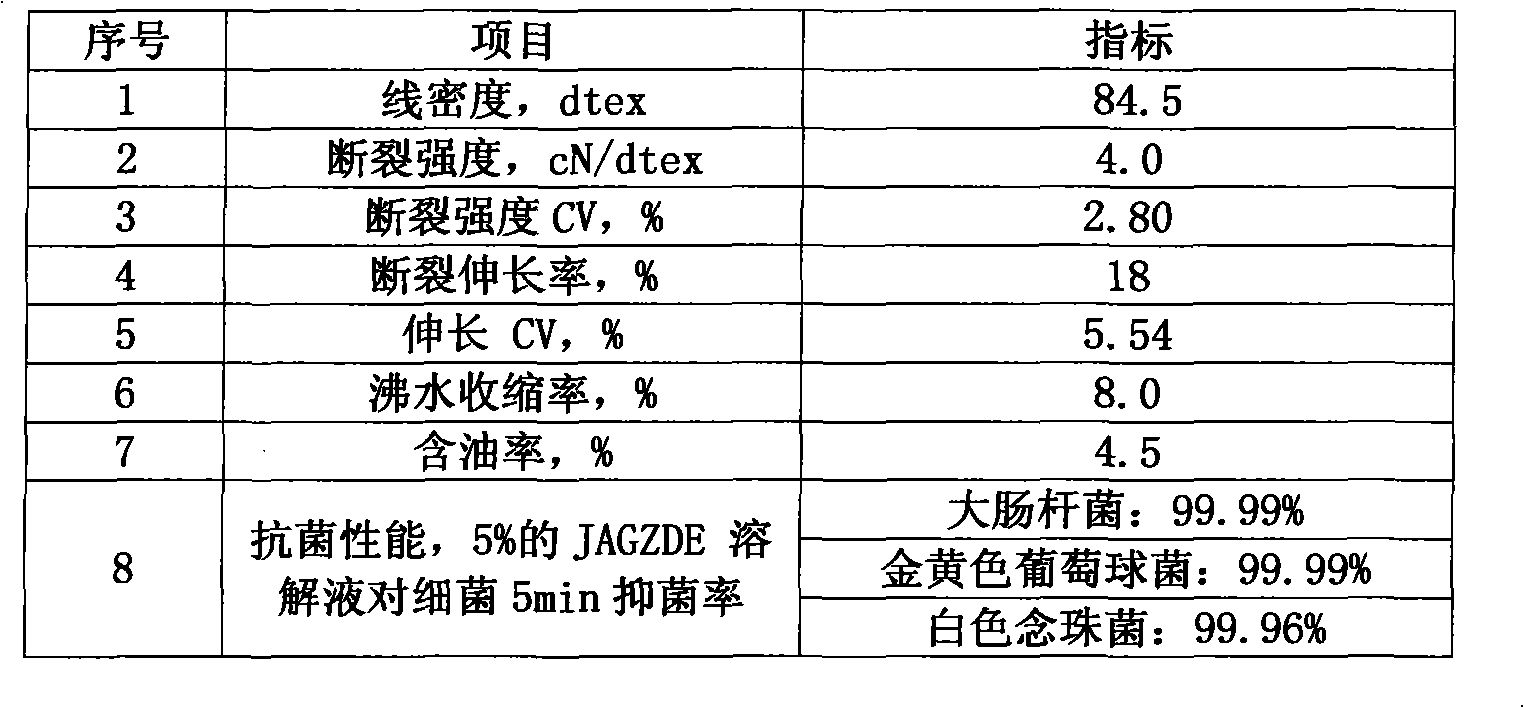

[0039] Weigh 0.25g of silver ion antibacterial agent loaded with titanium phosphate salt with a particle size of 30nm and blend with 1.25kg of dried PET chips to prepare antibacterial PET masterbatch, add this antibacterial masterbatch to 30kg of dried PET / PBT (PET / PBT=80 / 20) slices, after blending, melting, using 13-hole multi-hole spinneret spinneret to spin, and obtaining PET / PBT POY fibers after winding. Under the conditions of 25°C and 65% relative humidity, after storing for one day, false twisting processing was carried out to obtain the physical properties of the antibacterial DTY yarn as shown in Table 2 below:

[0040] Table 3 Physical properties of PET / PBT antibacterial silk

[0041] Specifications: 83dtex / 72f

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com