Scanning type glass color difference measuring device and measuring method thereof

A technology of measuring device and measuring method, applied in the fields of quality monitoring and coated glass production, can solve the problems of high labor intensity, low efficiency, poor measurement effect, etc., and achieve the effect of improving production efficiency, high efficiency and small representative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The present invention will be further described below in conjunction with the examples, in order to help readers better understand the essence of the present invention, but does not constitute any limitation to the implementation and protection scope of the present invention.

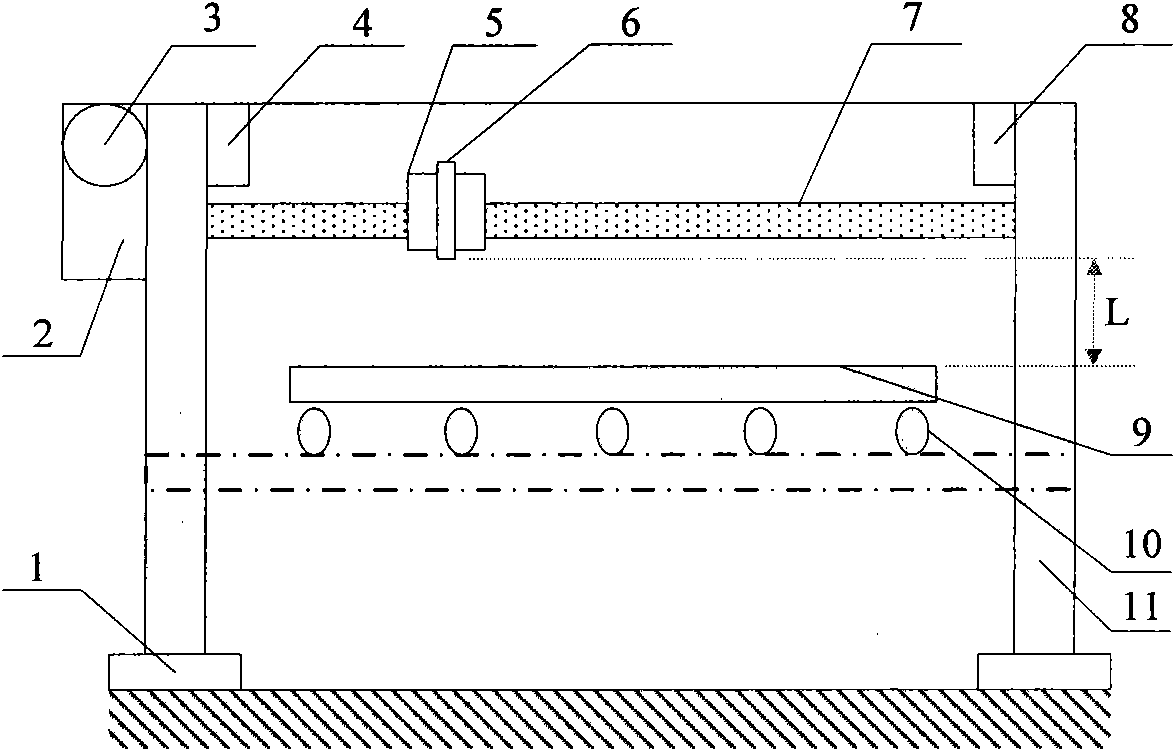

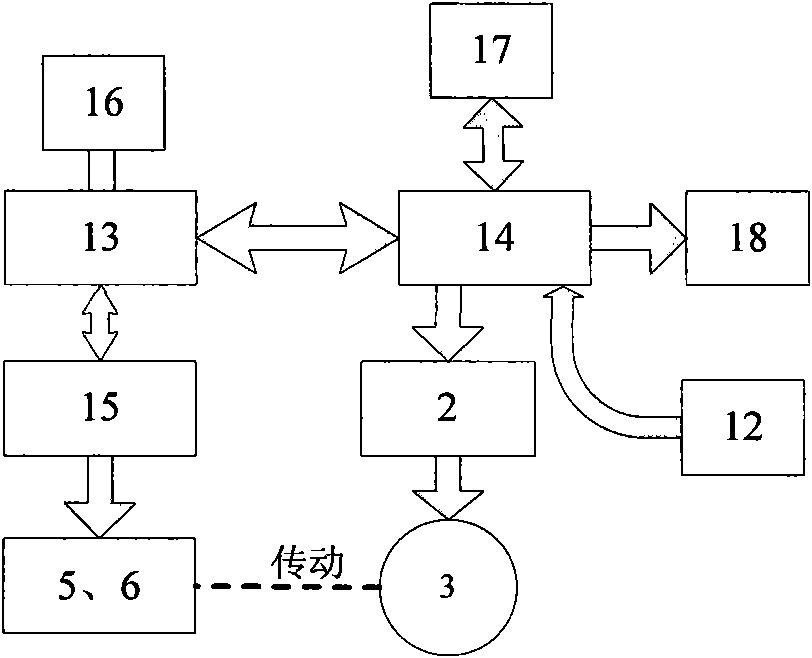

[0028] Use the scanning glass color difference measuring device to measure the glass color difference parameters in the production line online. The color difference data collector 15 adopts a fiber optic spectrometer with a USB2.0 interface. The spectrometer uses an ILX554 2048-pixel linear array CCD detector with a focal length of 75mm, a measurement wavelength range of 200-1100nm, and a maximum resolution of 0.04nm; the light source A low-voltage halogen tungsten lamp with a wavelength range of 360nm to 2000nm is used, and its stability is less than 2%.

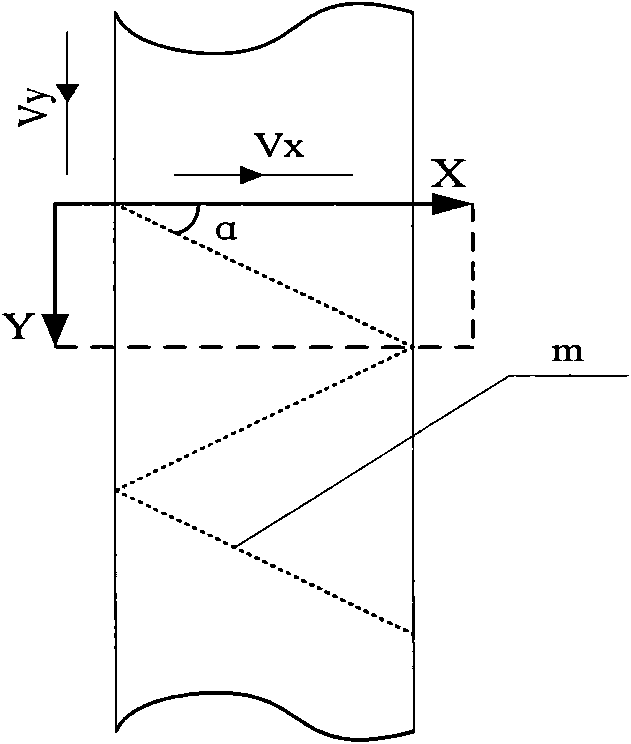

[0029] The optical probe 6 is a multi-core optical fiber, including a light source beam and a receiving detection beam. The optical axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com