Oxidizing solution separator provided with gas-liquid separating spray nozzle

A liquid separation and oxidizing liquid technology, applied in the direction of using liquid separation agent, separation method, dispersed particle separation, etc., can solve the problems of chaotic gas-liquid interface, large pipeline vibration, hidden safety hazards, etc., to achieve stable gas-liquid interface, eliminate liquid Vortex, prevent fire explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The oxidation liquid separator with gas-liquid separation nozzle of the present invention will be described in detail below with reference to the accompanying drawings.

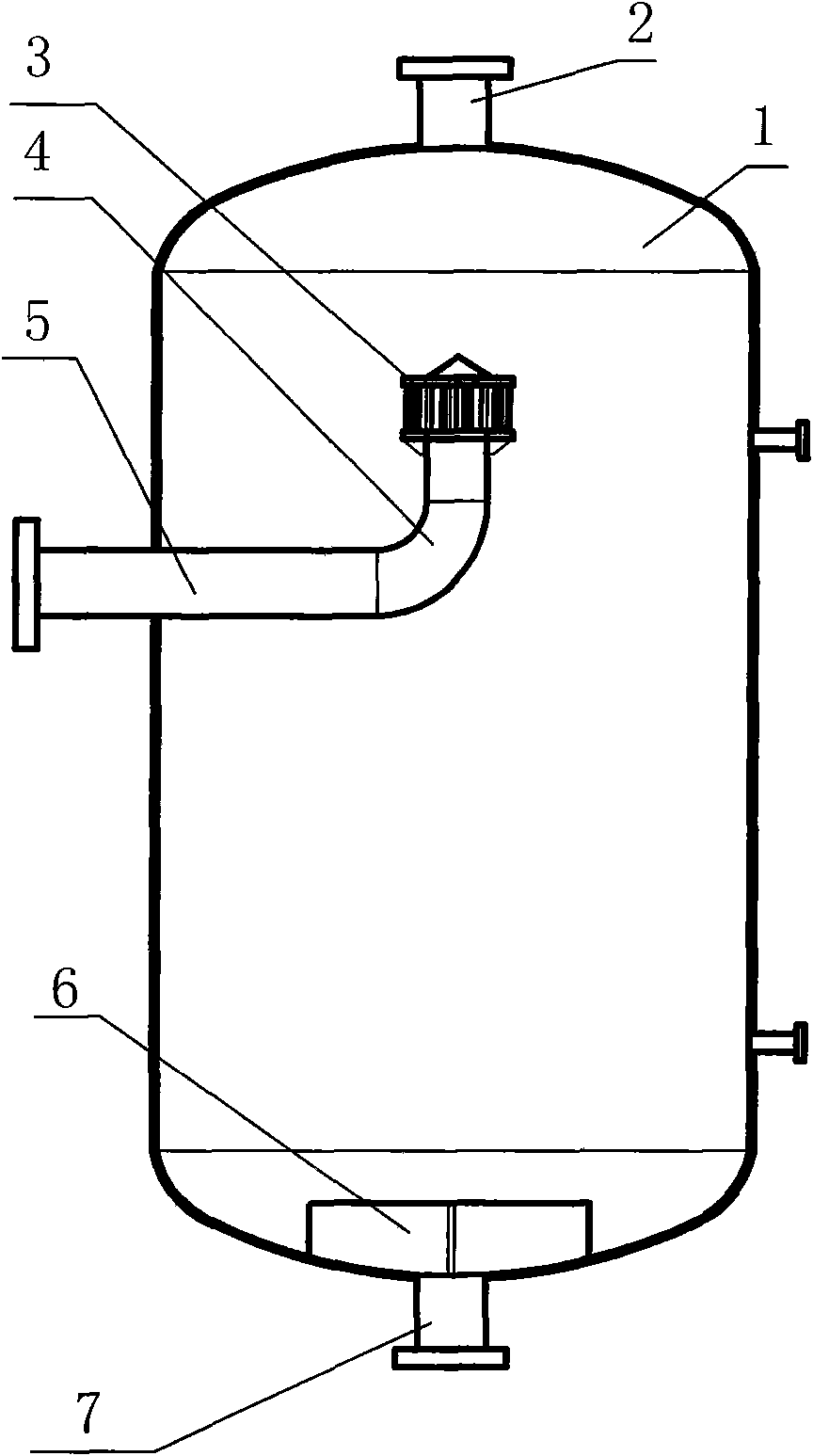

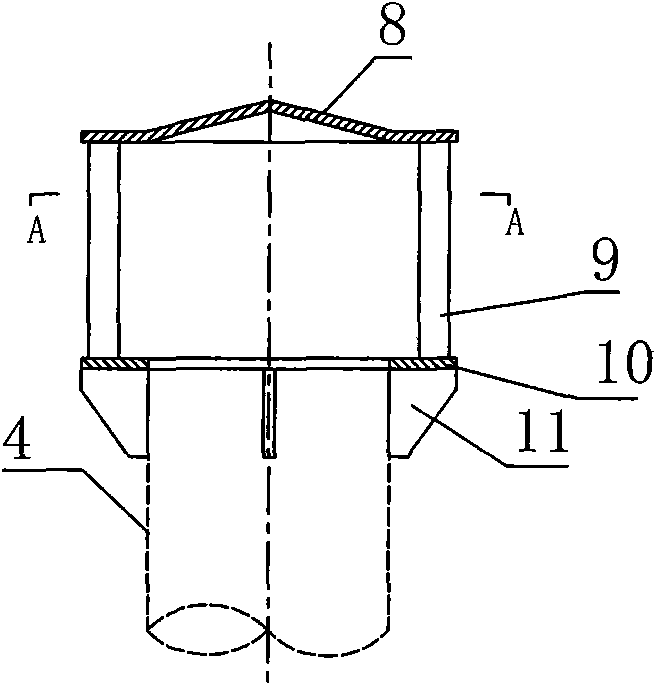

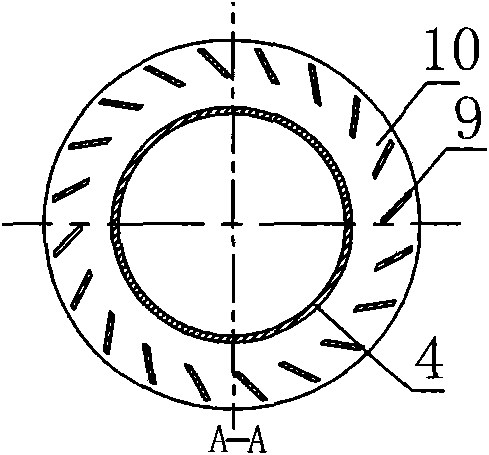

[0019] The structure of the oxidizing liquid separator with gas-liquid separation nozzle of the present invention is composed of a shell 1, a material inlet 5 and a material outlet 7, and the material inlet end in the shell 1 is connected by an upwardly bent elbow 4. The swirl nozzle 3 is provided with an anti-rotation stabilizer 6 above the material outlet 7 at the bottom of the shell 1, wherein the swirl nozzle 3 is composed of a cap 8, guide vanes 9 and an annular base 10, and the guide vanes 9 are vertical Welded between the cap 8 and the annular base 10, the bottom of the annular base 10 is provided with a rib plate 11, the annular base 10 is connected with the upper end of the elbow 4 through the rib plate 11, and the anti-rotation current stabilizer 6 is made of stainless steel plate Vertical we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com