Less weight material, micro-weight material, zero weight material and minus weight material and manufacture method thereof

A production method and zero-weight technology, applied in aircraft parts, ship construction, ships, etc., can solve problems such as unsafe, inexperienced, and inflexible, and achieve the effects of reducing weight, increasing speed, and increasing voyage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

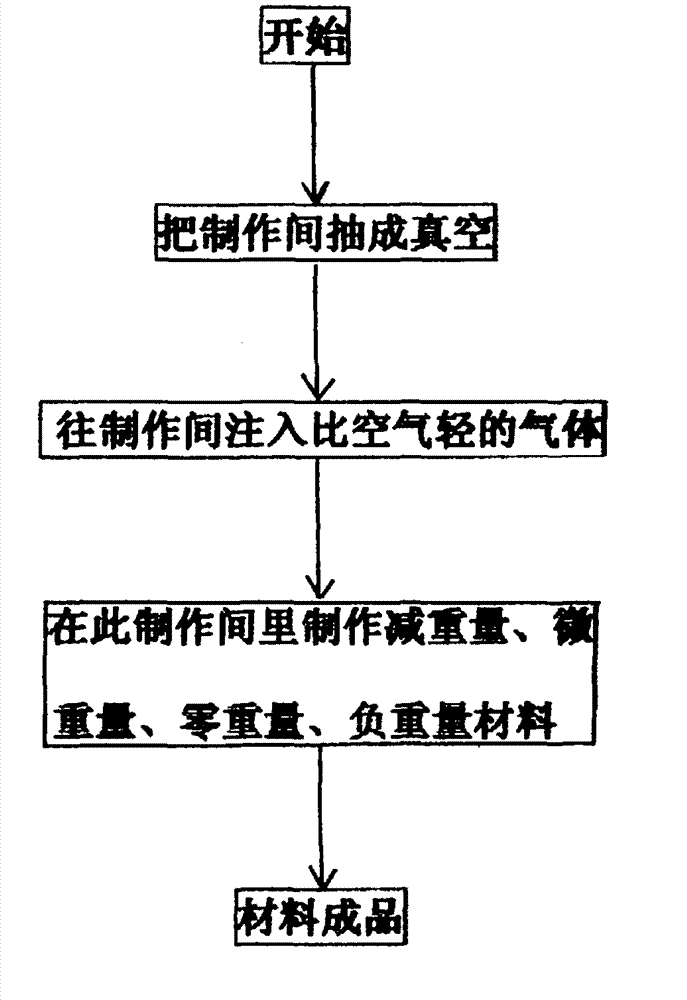

[0013] The first step is to evacuate the production room.

[0014] In the second step, constant-pressure helium (for example, helium at a constant pressure of 1 atmosphere) is injected into the fabrication room.

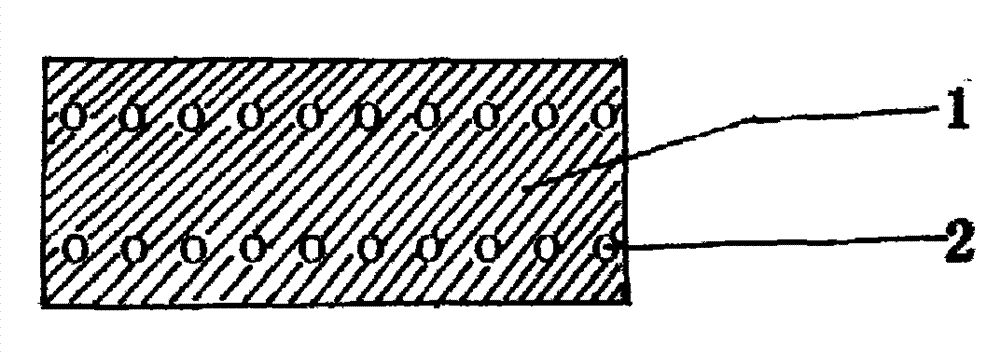

[0015] In the third step, in the production room, semi-finished raw materials (such as plastic male and female parts with open spaces) are used to reserve open spaces. 1, due to the constant pressure of helium in the production room, The open spaces of the plastic male and female parts have been permeated with helium gas, and people wear oxygen masks and glue them together by hand (such as bonding with adhesives) to produce a weight-reducing, micro Weight, zero weight, negative weight material.

[0016] The material produced is lighter than the raw material is the weight-reducing material, the material produced is slightly heavier than the micro-weight material, the material produced has no weight is the zero-weight material, and the material produced is lighter tha...

Embodiment 2

[0018] The first step is to evacuate the production room.

[0019] In the second step, constant-pressure hydrogen gas (for example, hydrogen gas at a constant pressure of 1 atmosphere) is injected into the production room.

[0020] In the third step, in the production room, semi-finished raw materials (such as plastic male and female parts with open spaces) are used to reserve open spaces one by one. 1, due to the constant pressure of hydrogen in the production room, the plastic The open spaces of the male and female parts have been permeated with hydrogen gas, and people wear oxygen masks and glue them together by hand (such as bonding with adhesives) to produce a weight-reducing, micro-weight, zero-weight material containing hydrogen 2. Weight, negative weight material.

[0021] The material produced is lighter than the raw material is the weight-reducing material, the material produced is slightly heavier than the micro-weight material, the material produced has no weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com