Preparation method of potassium aurous cyanide

A technology of potassium aurocyanide and potassium cyanide, applied in the directions of coordinating cyanide, metal cyanide, electrolysis process, etc., can solve problems such as being unsuitable for large-scale production, achieve high direct yield, improve current efficiency, and facilitate feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

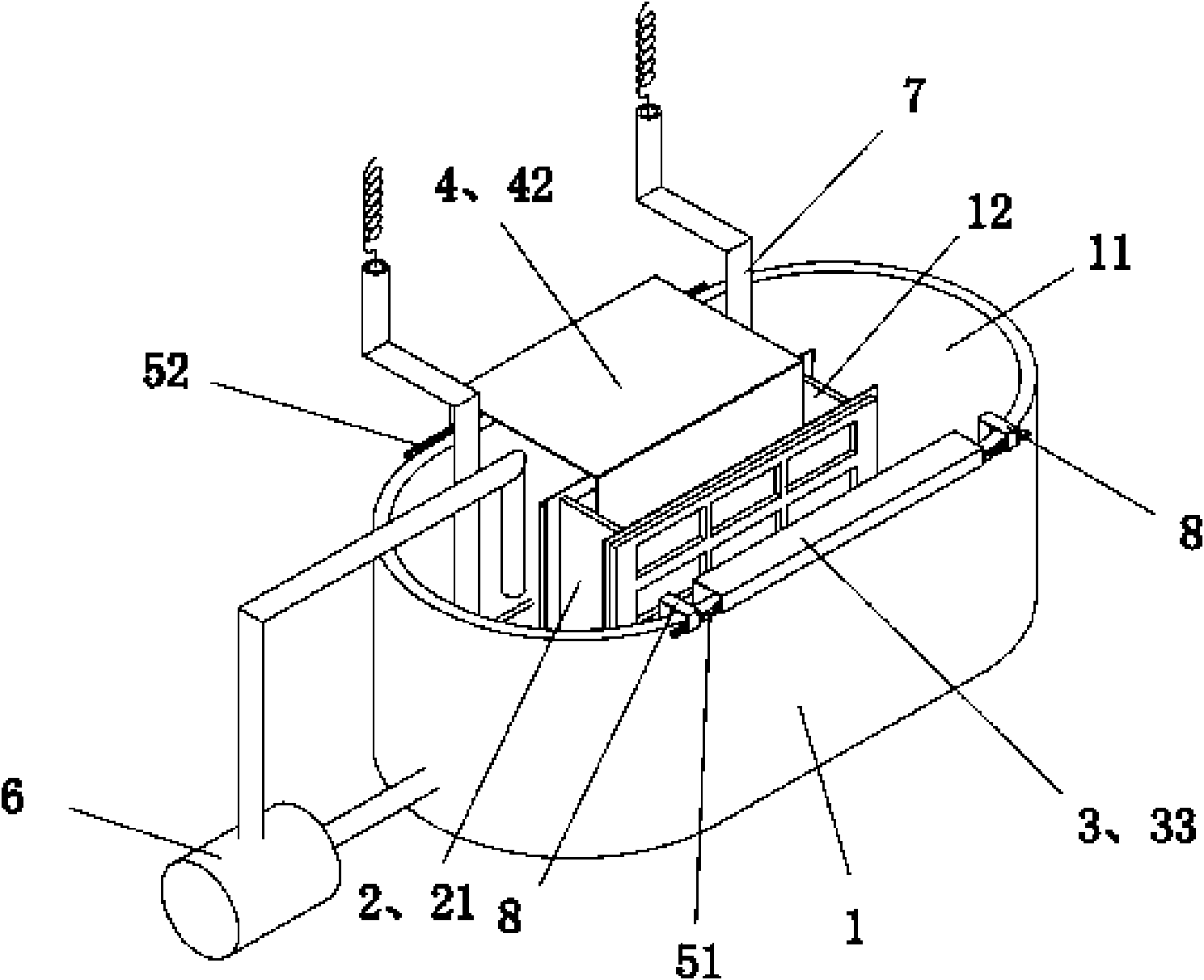

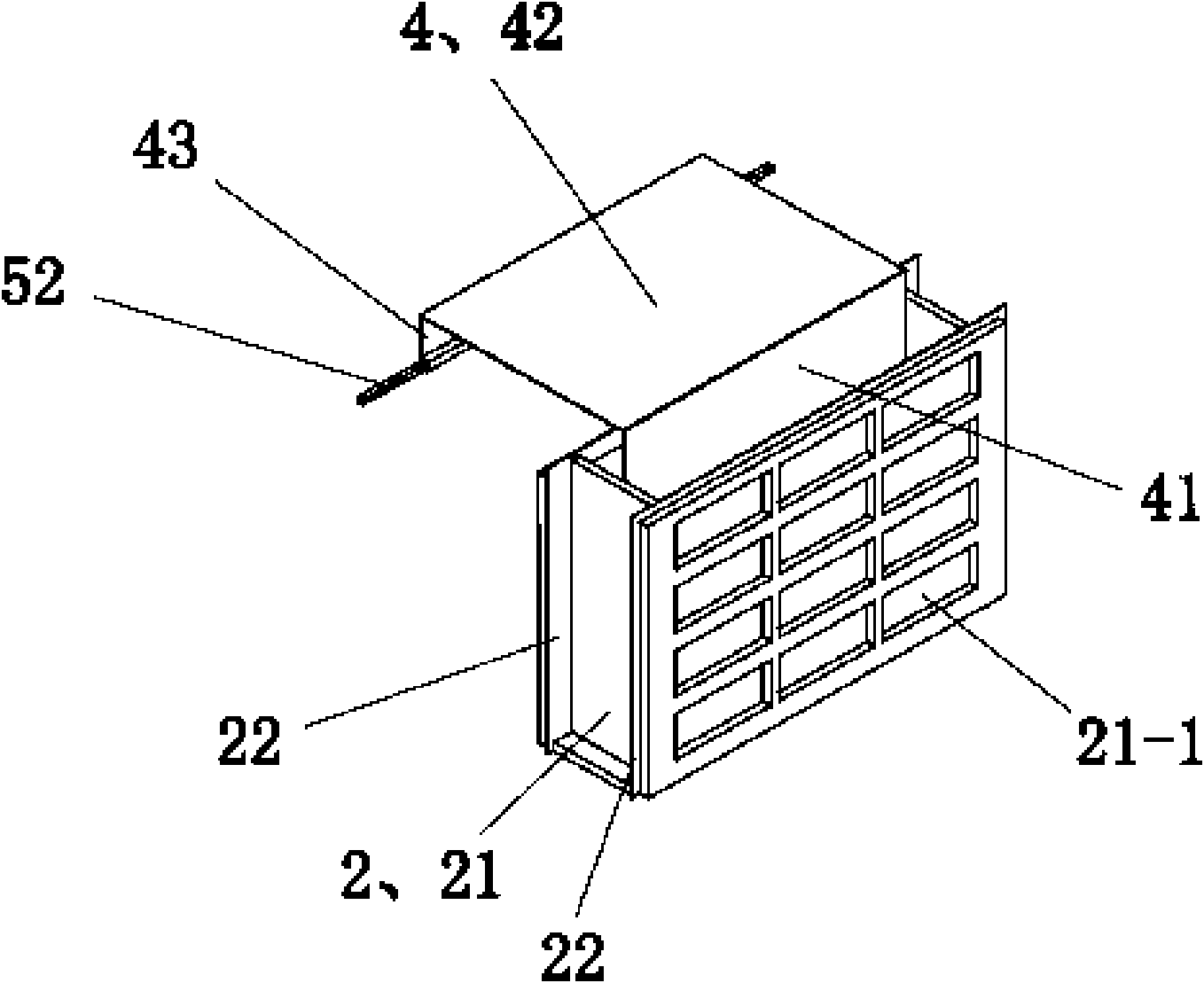

[0036] See figure 1 The device used in the preparation method of potassium aurous cyanide of the present embodiment comprises an electrolytic cell 1, a diaphragm tank 2, an anode plate 3, a cathode plate 4, an anode rod 51, a cathode rod 52, a circulating water pump 6 and a heating tube 7.

[0037] The electrolytic cell 1 is composed of a waist-circular tank bottom plate and a waist-circular wall plate fixed around the tank bottom plate, and the material is polytetrafluoroethylene or plexiglass.

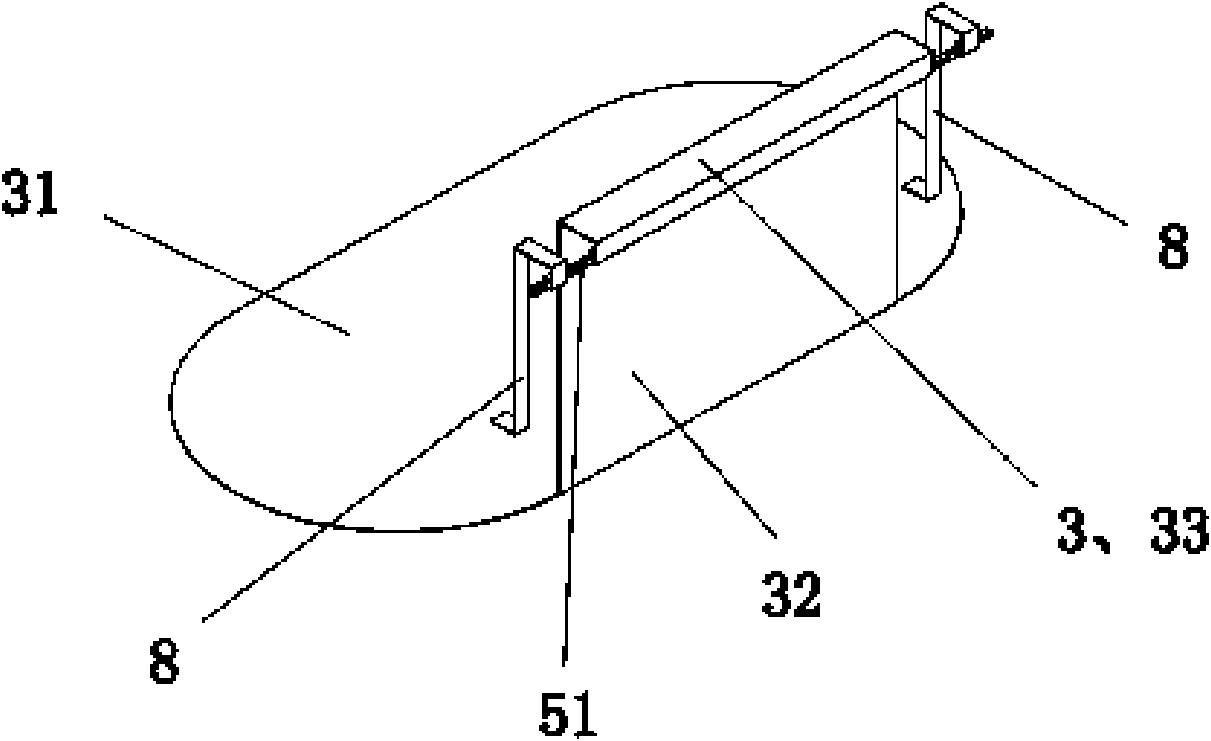

[0038] See figure 2 , the anode plate 3 is a one-piece folded plate made of iridium-coated titanium plate (MMO). The anode plate 3 includes a bottom plate 31 located on the bottom plate of the electrolytic cell 1 , a side plate 32 located on the inside of the front side cell wall of the waist circular wall plate of the electrolytic cell 1 , and an outer plate 33 extending out of the electrolytic cell 1 .

[0039] The anode rod 51 is a copper rod or a silver rod. Also fixedly conn...

Embodiment 2~ Embodiment 6

[0050] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0051] Table 1

[0052] Example 1

Embodiment 7

[0054] The rest of this embodiment are the same as Embodiment 1, the difference is: see Figure 4 and Figure 5 , there is no fixed connection thick gold sheet 8 on the anode rod 51, the time of current sudden drop will be extended to 18 hours like this. The weight of potassium aurous cyanide obtained at last is 33.024kg, and yield is 90.3%, and gold content is 68.36%, and is all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com