Bend insensitive single mode optic fiber with large effective area and manufacturing method thereof

A bending-insensitive, effective area technology, applied to multi-layer core/cladding optical fibers, cladding optical fibers, manufacturing tools, etc., can solve the problems of optical fiber mismatch, increased optical fiber connection loss, and high optical fiber manufacturing costs. The effect of low light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with embodiment.

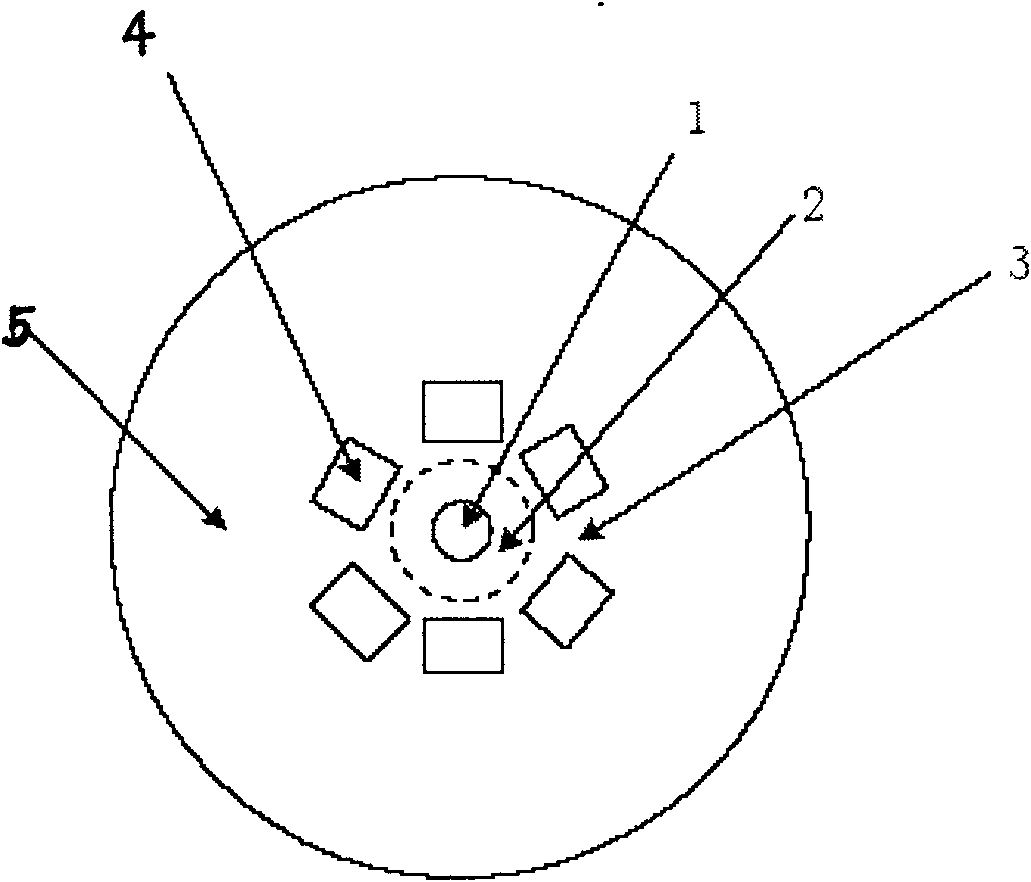

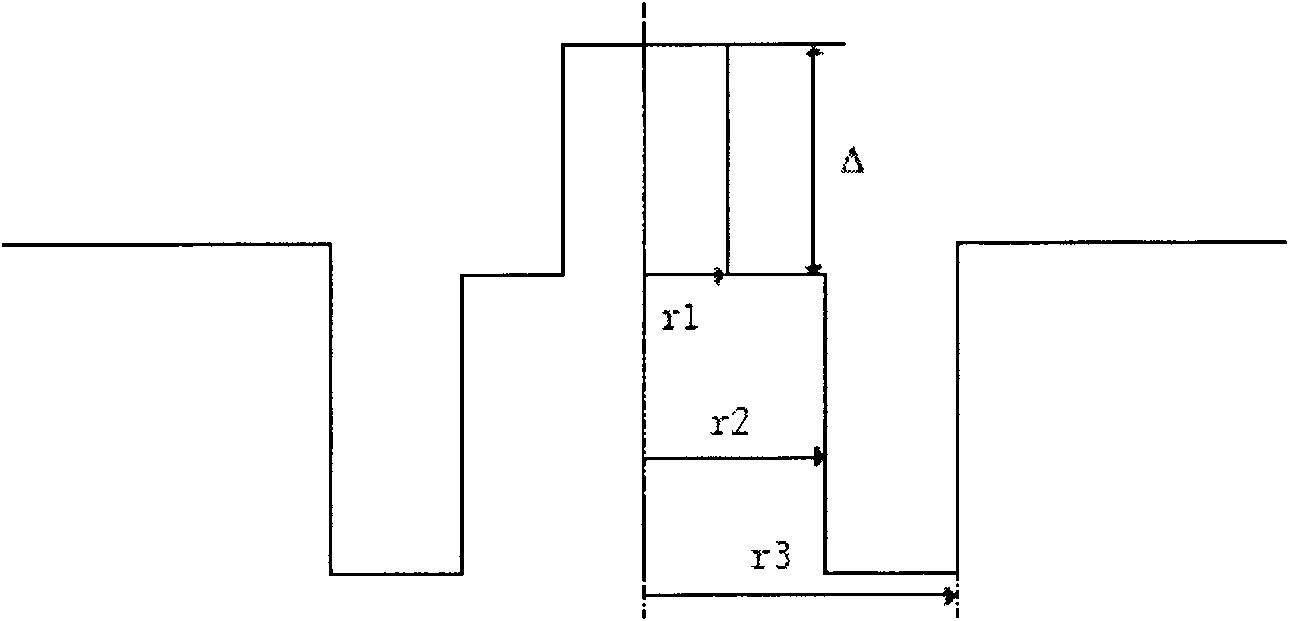

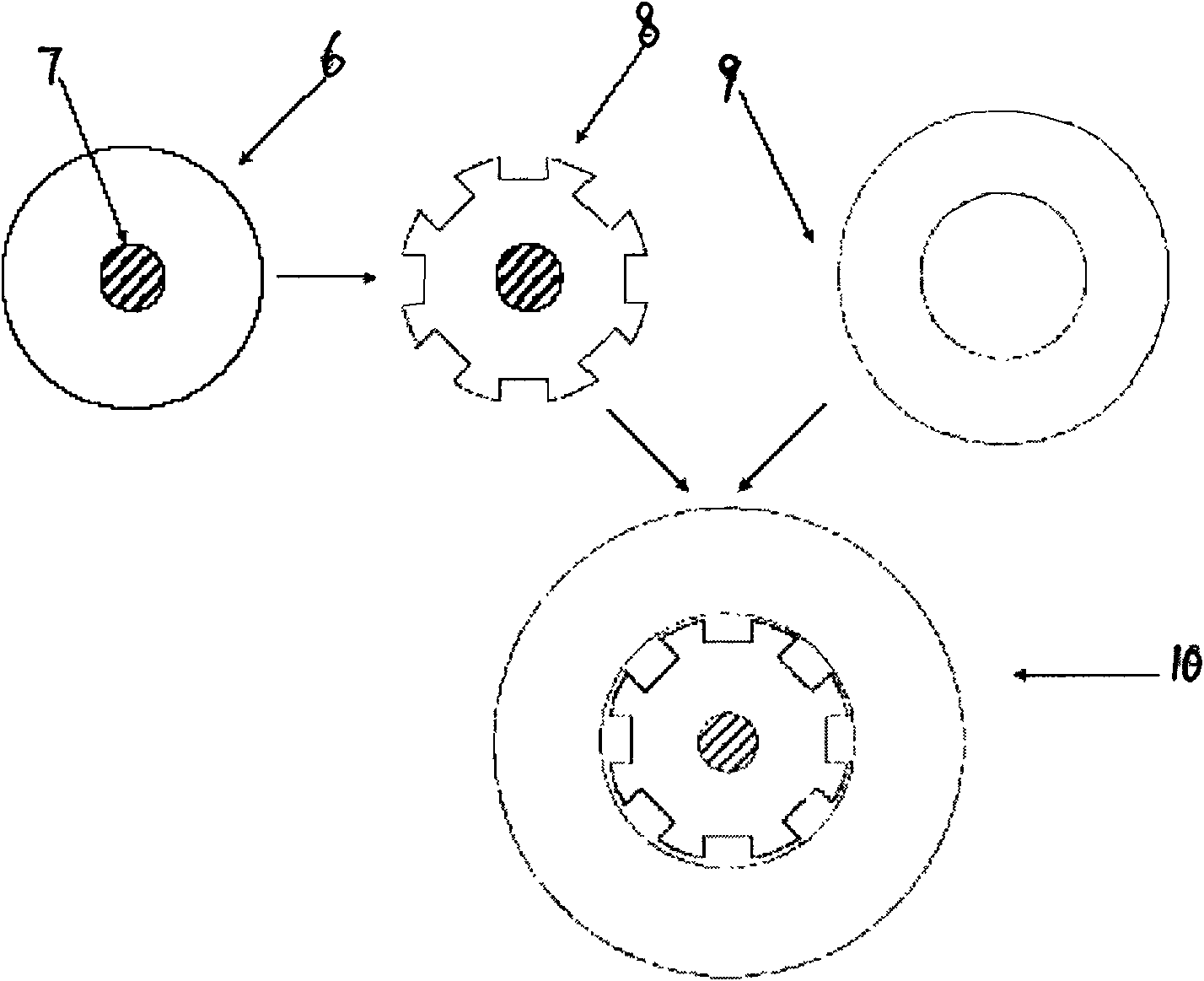

[0035] The G.652 low water peak optical fiber core rod is prepared by PCVD process, and the surface is opened in an approximate square along its axial direction (because the core rod is cylindrical, so the outer edge of the groove is arc-shaped,) the groove is grooved on the side. The central mandrel, the slots are uniformly distributed in the circumferential direction; after cleaning and drying, the RIC process is used to assemble the RIC process preform with the high-purity quartz tube. The main parameters of the preform are shown in Table 1; the RIC preform is directly drawn , using optical fiber coating materials for single-mode optical fiber production, the drawing speed is 800 m / min, the diameter of the optical fiber is 125±0.7μm, and the internal pressure of the RIC is controlled to be 800-950mbar. Analyze the end face of the optical fiber with a microscope to confir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com