Method for producing integral ceramics metal halide electric arc tube

A technology for a ceramic metal halide lamp and a manufacturing method, applied in the field of electric light sources, can solve the problems of uneven temperature distribution, lamp failure, stress concentration, etc., and achieve the effects of simple and reliable manufacturing process, reduced production cost, and no stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further elaborate the technical means and effects adopted by the present invention to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention should be able to gain a deep and specific understanding from this , however, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

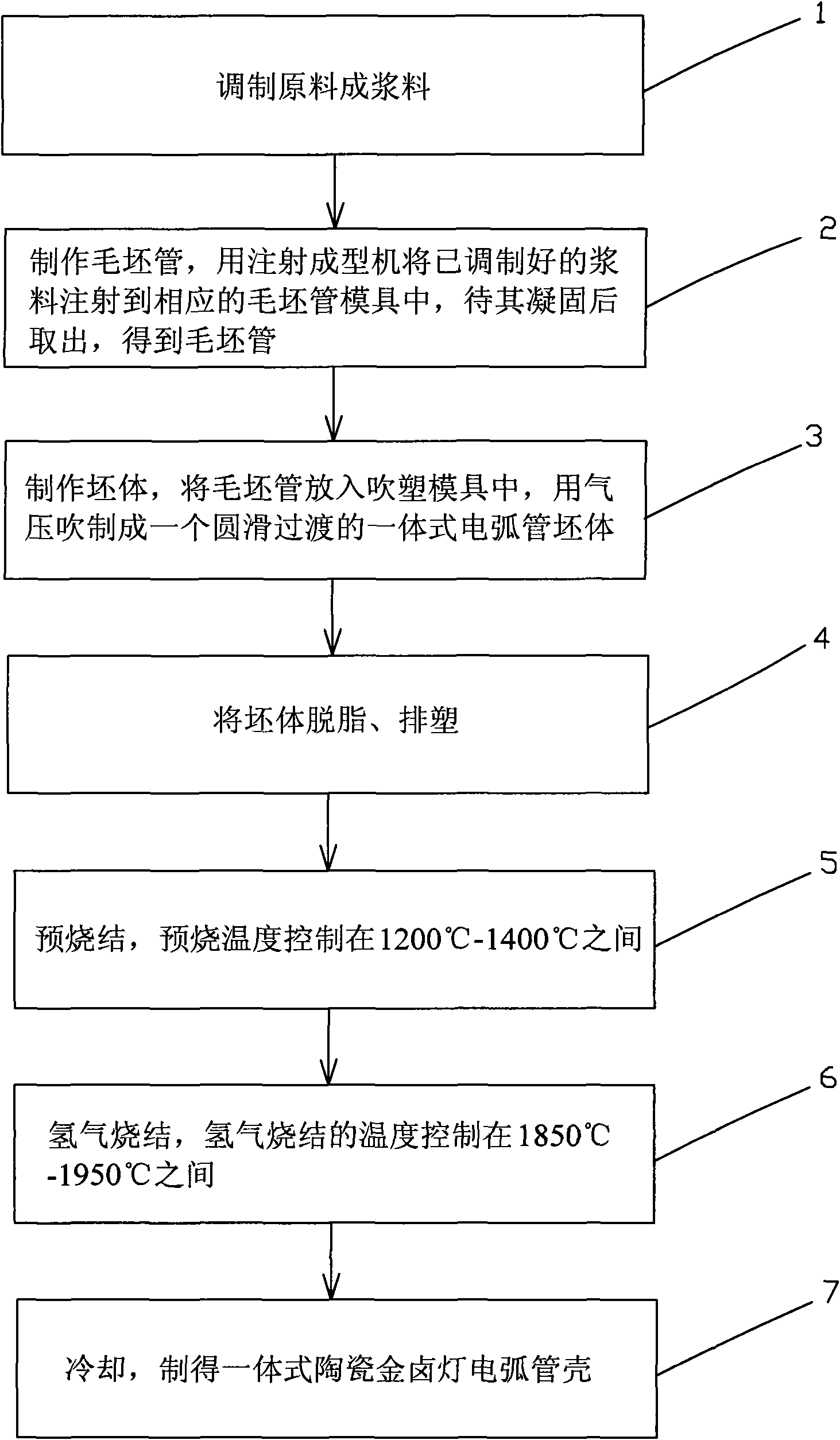

[0032] Such as figure 1 As shown, the manufacturing method of the integrated ceramic metal halide lamp arc tube of the present invention comprises:

[0033] Step 1, preparing raw materials into slurry, the composition and content (by weight) of the raw materials are as follows: 11-17 parts of paraffin wax; 11-17 parts of microcrystalline wax; 1-3 parts of stearin wax; 65-75 parts of plastic ; High-purity alumina 500-1000 parts. The plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com