Micro-strip resonator based on substrate integration waveguide

A technology for integrating waveguides and resonators on a substrate, applied in resonators, waveguide-type devices, electrical components, etc., can solve the problem of low Q value, and achieve the effect of improving Q value, easy to use, and compact design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

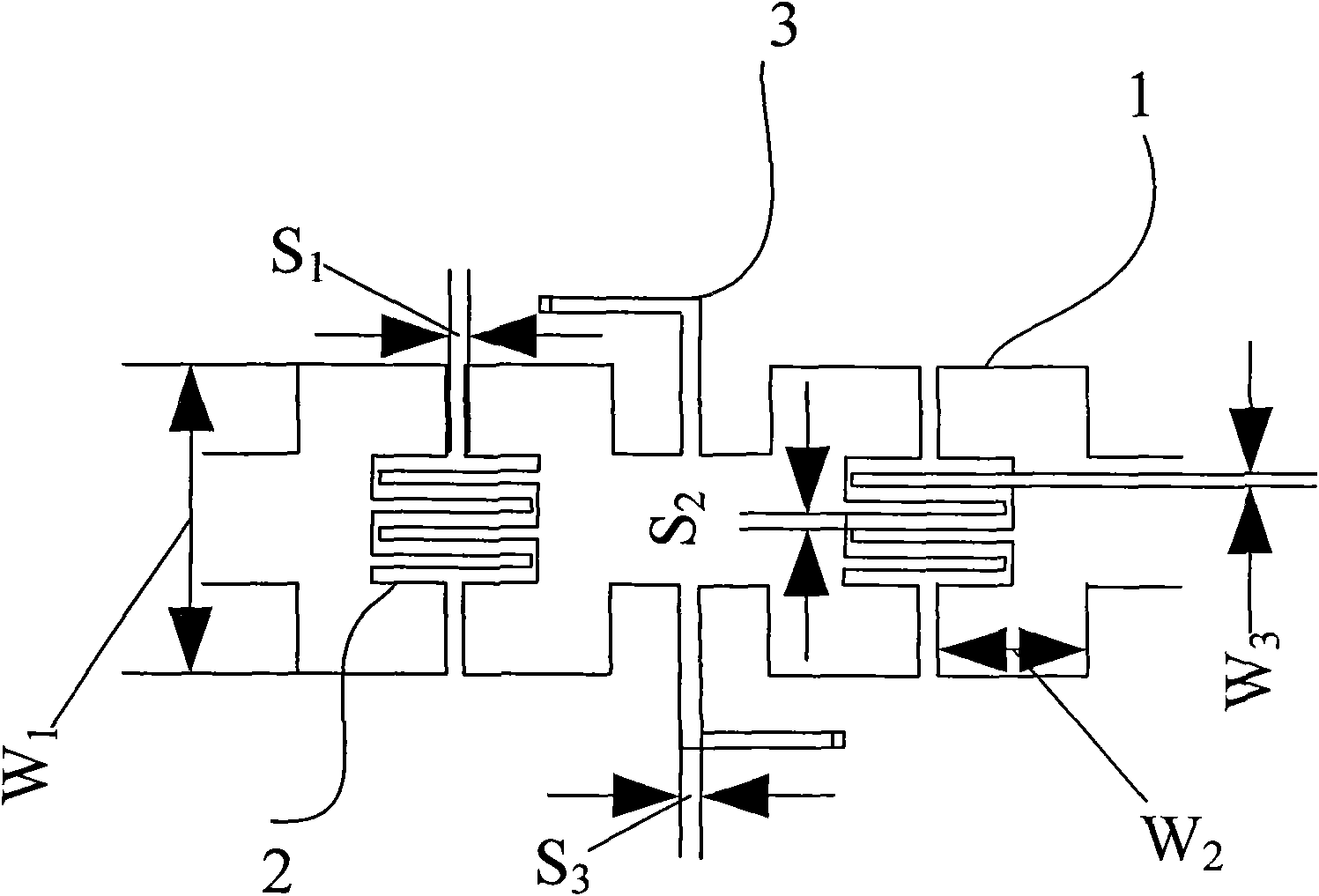

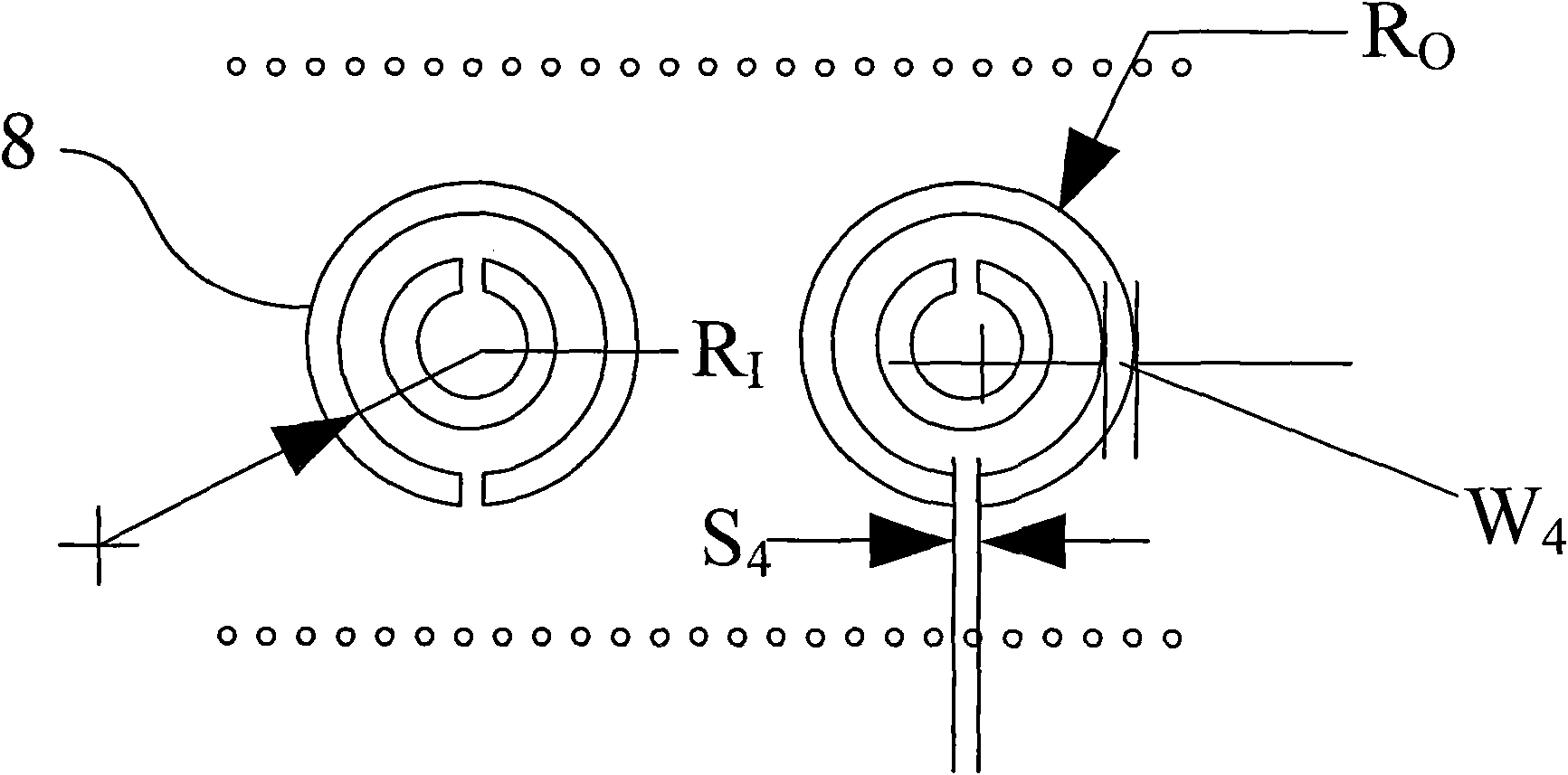

[0015] exist figure 1 Among them, the unit cell structure 1 of a conventional CSRR resonator consists of a series of interdigitated capacitors 2 and a pair of branch inductors 3, and is short-circuited to the ground plane through vias 5; according to the interdigitated capacitors, an opening is etched in the ground plane Resonant ring 8; CSRR is a material with negative permittivity and magnetic permeability at the same time.

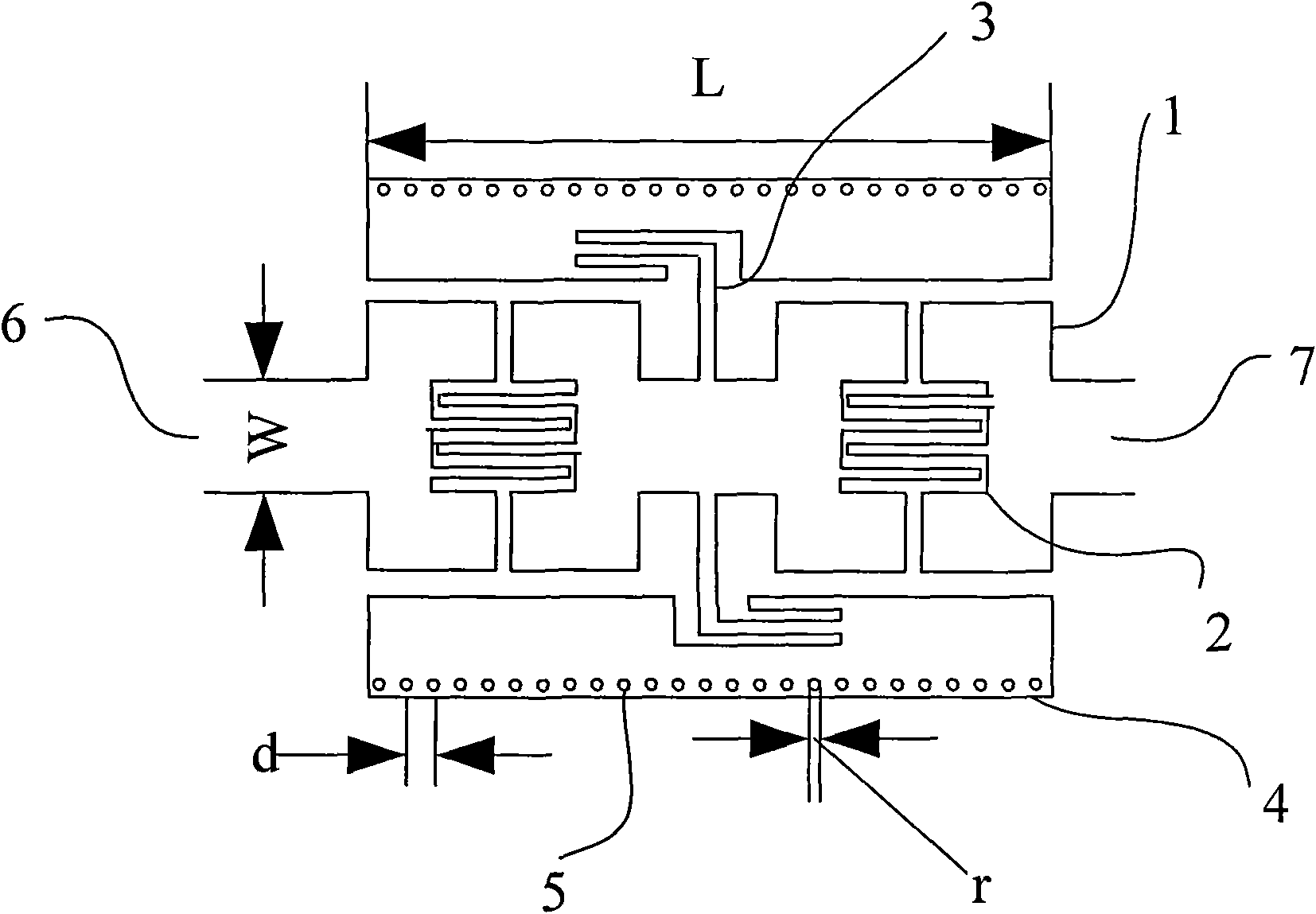

[0016] The microstrip resonator of this embodiment is loaded with SIW structure 4 on the two sides of conventional CSRR resonator; It is realized by punching a series of metal through holes 5 . The signal is input from the input port 6 and output from the output port 7; the through hole 5 limits the propagation of the electromagnetic field in the SIW; the SIW structure 4 based on the substrate integrated waveguide is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com