Method for preparing special product from carbon fiber

A technology of carbon fiber and plain fiber, which is applied in the field of carbon fiber production products, can solve the problems of insufficient carbon fiber layer pressure, uneven inner wall, and affecting product strength, etc., to achieve uniform force, convenient coating, and energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

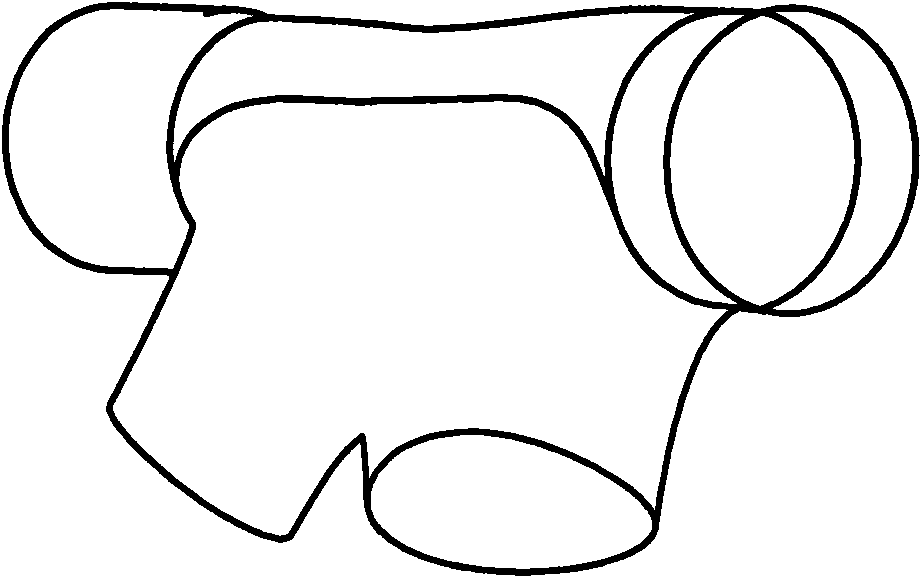

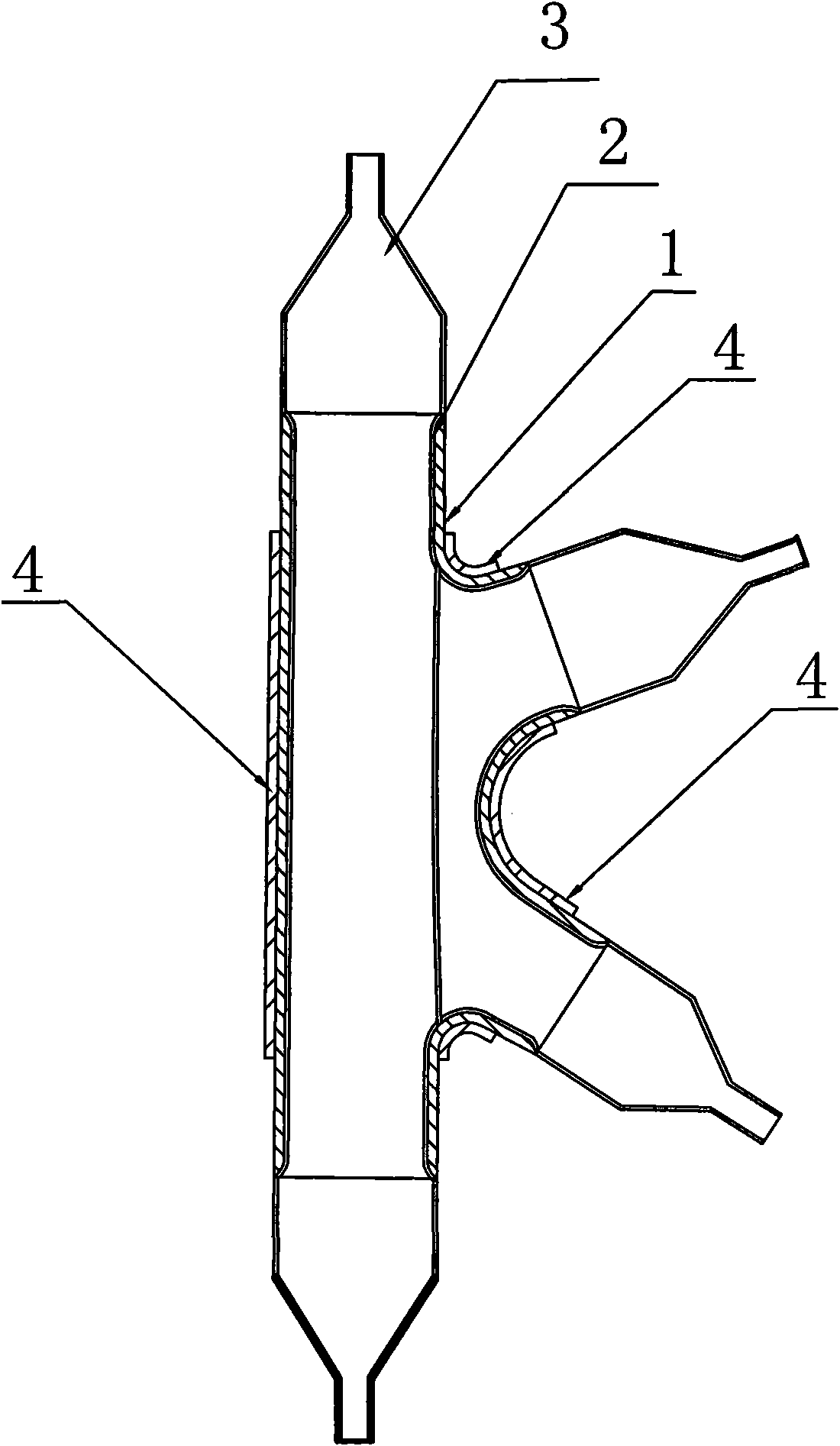

[0030] Embodiment 1, a method for making special-shaped products with carbon fiber, the structure of the special-shaped products is as follows figure 1 Shown, its preparation method comprises the following steps:

[0031] 1). The air bag mandrel 1 is molded with silica gel material. The air bag mandrel 2 conforms to the shape of the product, the size is slightly smaller, the interior is a hollow cavity, and there are two sets of channels; the air bag mandrel has a wall thickness of 1 For: 2.5mm, hardness: 40 Shore A, elongation: 250%, tensile strength: 7Mpa, tensile strength: 19 / M.

[0032] Since the air bag mandrel made of silicone material is easy to demould, the air bag mandrel 1 can form a product with a large inner cavity section and a small end;

[0033] 2). Nylon long bags 2 are respectively arranged in two groups of passages of the air bag mandrel 1, and the two ports of the nylon long bags are respectively provided with air nozzles 3, each forming a closed air cavity...

Embodiment 2

[0042] Embodiment 2, a method of making special-shaped products with carbon fiber, differs from Example 1 in that: the air bag mandrel 1 is formed with rubber material, and the air bag mandrel 2 conforms to the shape of the product, and its size is slightly smaller. It is a hollow cavity with two sets of channels; the wall thickness 1 of the mandrel of the air bag is: 3mm, the hardness is: 60 Shore A elongation: 350%. Tensile strength: 8Mpa. Tensile strength: 20 / M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com