Treatment process of copper-iron-contained high-concentration acidic mine wastewater

A mine acid wastewater treatment technology, applied in the field of copper and iron high concentration mine acid wastewater treatment, copper and iron high concentration mine acid wastewater treatment process, can solve the problem that is not suitable for high concentration acid wastewater treatment, metal ion tolerance Poor, low treatment efficiency and other issues, to achieve the effect of comprehensive process recycling with good benefits, low price and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

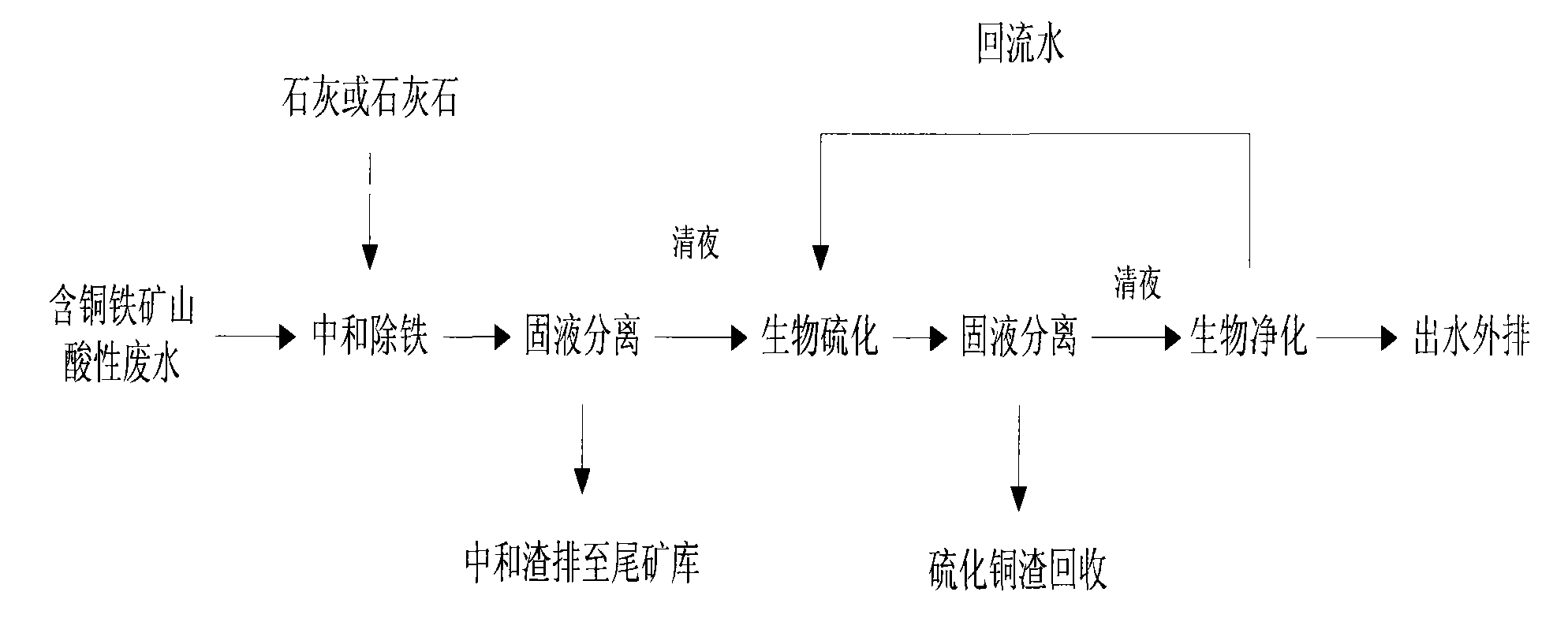

[0046] Such as figure 1 Shown, according to a kind of copper-iron-containing high-concentration mine acid wastewater treatment process that the present invention proposes, comprise following sequence process step and condition:

[0047] The first step: neutralize and remove iron, add lime or limestone to the acid wastewater of copper-containing iron mines to adjust the pH value of the wastewater to 2.5-3.5, so that the ferric iron in the wastewater can generate Fe(OH) 3 Neutralize slag;

[0048] The second step: solid-liquid separation, the clear liquid after neutralization and iron removal and the neutralization slag are subjected to solid-liquid separation, and the separated neutralization slag is sent to the tailings pond;

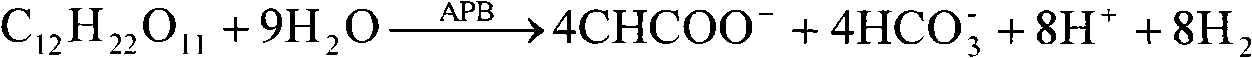

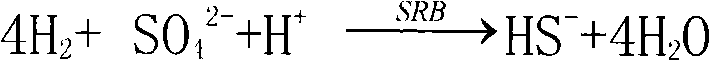

[0049] The third step: biological vulcanization, the clear liquid after solid-liquid separation A is mixed with the reflux water after the fifth step biological purification, the mixing ratio is 1:3-10, and the pH value after mixing is controlled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com