Multi-element composite micro-alloying copper alloy with high strength and high conductivity and preparation method thereof

A technology of micro-alloying and copper alloying, applied in the field of high-strength and high-conductivity copper alloy preparation, can solve the problems of insufficient strength, poor plasticity, and difficulty in achieving high-strength and high-conductivity matching, and achieve the control of product performance and plasticity. Excellent, easy-to-operate and mass-produced results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

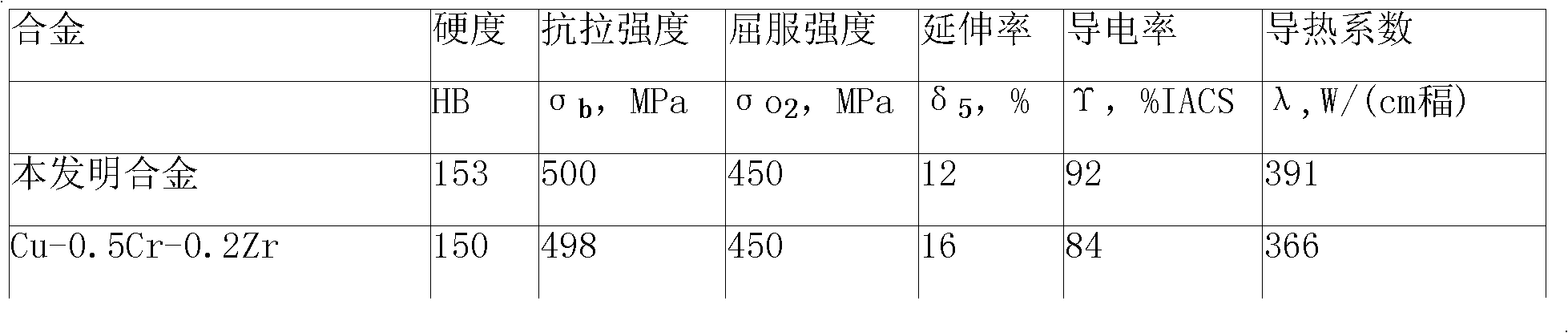

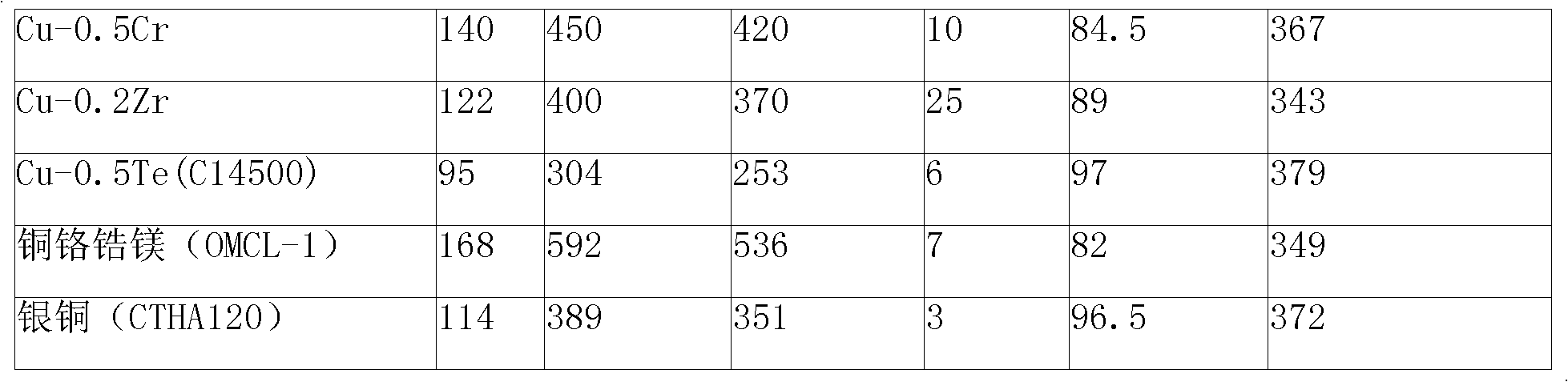

[0023] (1) Chemical composition (mass fraction, %) of alloy of table 1

[0024] Alloy

Cr

Zr

Te

Cu

Cu-Cr-Zr-Te

0.2-0.8

0.1-0.3

0.1-0.5

Bal.

[0025] (2) Melt copper, chromium, zirconium, and tellurium in a melting furnace according to the contents required in Table 1. After the electrolytic pure copper is completely melted, add industrial pure chromium and zirconium, and then heat up to 1450°C for 20 minutes, and then cool down to 1100°C. Then add commercially pure tellurium and keep it warm for 30 minutes. After the melt is refined and degassed, it is semi-continuously cast into a flat ingot.

[0026] (3) Homogenize the slab at a temperature of 800°C-900°C for 4h-12h, then air-cool. The homogenized ingot is kept at a temperature of 850°C-920°C for 1h-2h, and then the ingot is hot-rolled through multiple passes to about 5mm and air-cooled. When rolling, the hot-rolled plate needs to be annealed at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com