Process for preparing sodium cantharidinate

A technology of sodium cantharidinate and cantharidin, applied in the direction of organic chemistry, etc., to achieve the effect of high purity and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

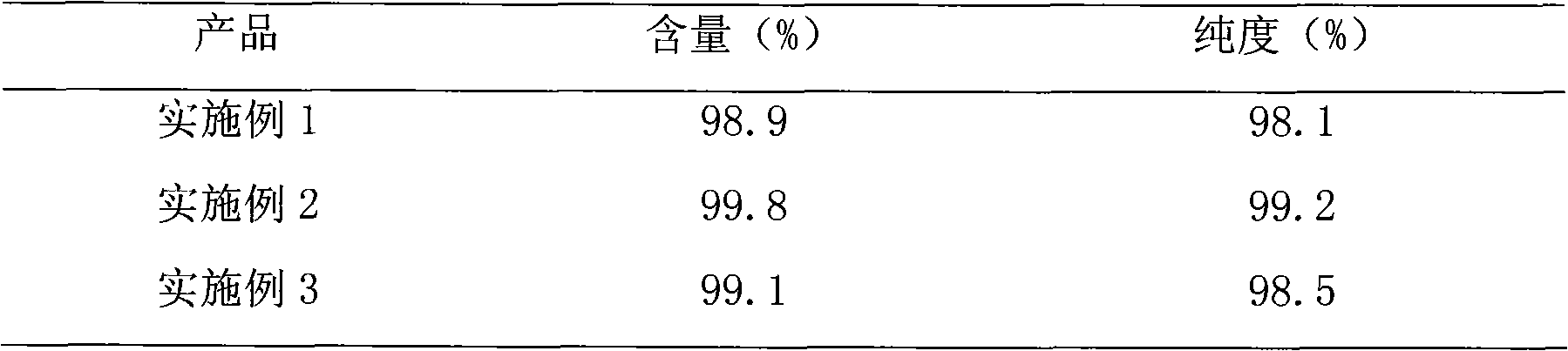

Examples

Embodiment 1

[0023] (1) The treatment of the cantharidin body.

[0024] Pick the dried cantharidin bodies that meet the standards of the National Pharmacopoeia, remove debris such as soil clods, and pulverize them so that the fineness of the cantharidin body powder is 20 mesh to 40 mesh.

[0025] (2) Extraction of cantharidin.

[0026] Put 100 kg of cantharidin body powder into a stainless steel extraction tank of 700 kg to 2000 liters of ethyl acetate saturated with hydrochloric acid in advance, soak for 16 hours, and stir once every half hour for the first 10 hours. Drain the leachate into storage tanks. Repeat the above operations, and then add 700 kg of ethyl acetate saturated with hydrochloric acid in advance to soak and extract once. Release the leaching liquid and combine it into the recoverer, heat it with steam to 50°C to concentrate, stop heating, and the recovered solvent will be used for the next extraction. After the leachate is drained, the insect residues are taken out an...

Embodiment 2

[0034] (1) The treatment of the cantharidin body.

[0035] Pick the dried cantharidin bodies that meet the national pharmacopoeia standards, remove soil clods and other sundries, and crush them so that the fineness of the cantharidin body powder is 20 mesh to 30 mesh.

[0036] (2) Extraction of cantharidin.

[0037] Put 100 kg of cantharidin body powder into a stainless steel extraction tank of 800 kg to 2000 liters of ethyl acetate saturated with hydrochloric acid in advance, soak for 16 hours, and stir once every half hour for the first 10 hours. Drain the leachate into storage tanks. Repeat the above operations, and then add 700 kg of ethyl acetate saturated with hydrochloric acid in advance to soak and extract once. Release the leaching liquid and combine it into the recoverer, heat it with steam to 50°C to concentrate, stop heating, and the recovered solvent will be used for the next extraction. After the leachate is drained, the insect residues are taken out and colle...

Embodiment 3

[0045] (1) The treatment of the cantharidin body.

[0046] Pick the dried cantharidin bodies that meet the standards of the national pharmacopoeia, remove soil clods and other sundries, and crush them so that the fineness of the cantharidin body powder is 30 mesh to 40 mesh.

[0047] (2) Extraction of cantharidin.

[0048] The formula ratio is:

[0049] Put 100 kg of cantharidin body powder into a stainless steel extraction tank of 900 kg to 2000 liters of ethyl acetate saturated with hydrochloric acid in advance, soak for 16 hours, and stir once every half hour for the first 10 hours. Drain the leachate into storage tanks. Repeat the above operations, and then add 700 kg of ethyl acetate saturated with hydrochloric acid in advance to soak and extract once. Release the leaching liquid and combine it into the recoverer, heat it with steam to 50°C to concentrate, stop heating, and the recovered solvent will be used for the next extraction. After the leachate is drained, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com