Neoprene closed cell foamed material and preparation method thereof

A technology of chloroprene rubber and foaming materials, which is applied in the field of high molecular polymers and its preparation, can solve the problems such as no neoprene foaming materials have been found, achieve good economic and social benefits, and the preparation process control is simple, The effect of reducing human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

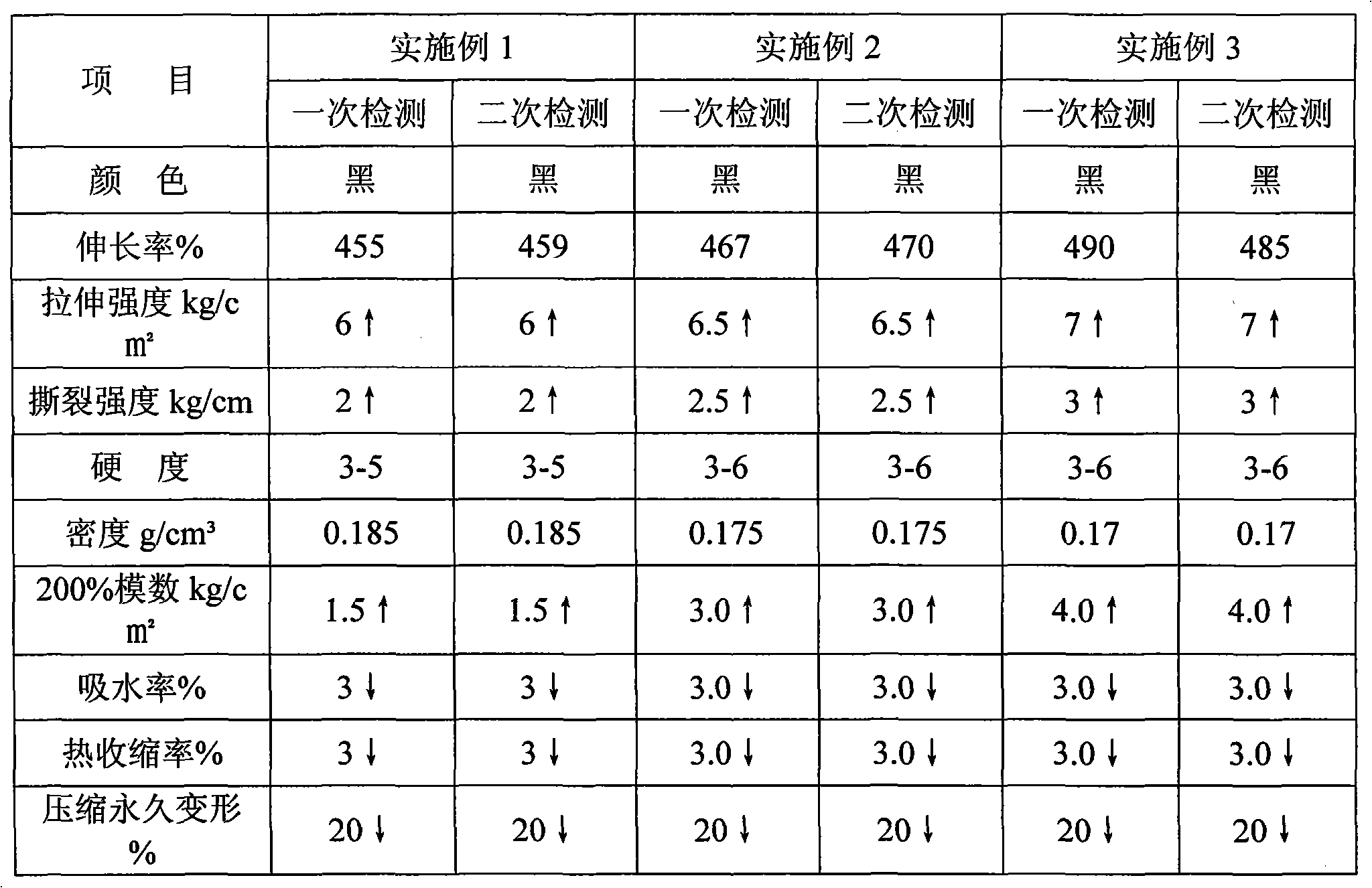

[0085] Embodiment 1-3 Neoprene closed-cell foaming material

[0086] Each raw material weight ratio (PHR) of embodiment 1-3 is as follows:

[0087] serial number

Embodiment 4

[0088] The preparation method of the neoprene closed-cell foam material of embodiment 4 embodiment 1

[0089] (1) Mastication

[0090] Put the chloroprene rubber into a 22-inch open mill for mastication, and the temperature of the rolls of the open mill is controlled at 50°C. First, pass it 3 times with a 5mm roll distance to make it soft under heat, and then pass it 3 times with a 3mm roll distance. Thin pass for 10 minutes with a small roller distance of 2.5mm, and finally the lower sheet is cooled and parked for 24 hours with a roller distance of 5mm;

[0091] (2) Mixing

[0092] A, the chloroprene rubber after step (1) is dropped into the feed chamber of 75L pressurized internal mixer and kneaded for 5 minutes, then magnesium oxide, antioxidant, dispersant are dropped into the feed chamber of internal mixer and kneaded for 5 minutes minute;

[0093] B. Put 1 / 2 of carbon black and magnesium powder into the material chamber of the internal mixer;

[0094] C. Put vaseline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com