Routine penetrometer

A penetrometer and casing technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of protection, radiation protection, special personnel supervision, complex safety facilities, in-situ testing and data inaccuracy. Retention and other issues, achieve considerable economic and social benefits, achieve construction quality management, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

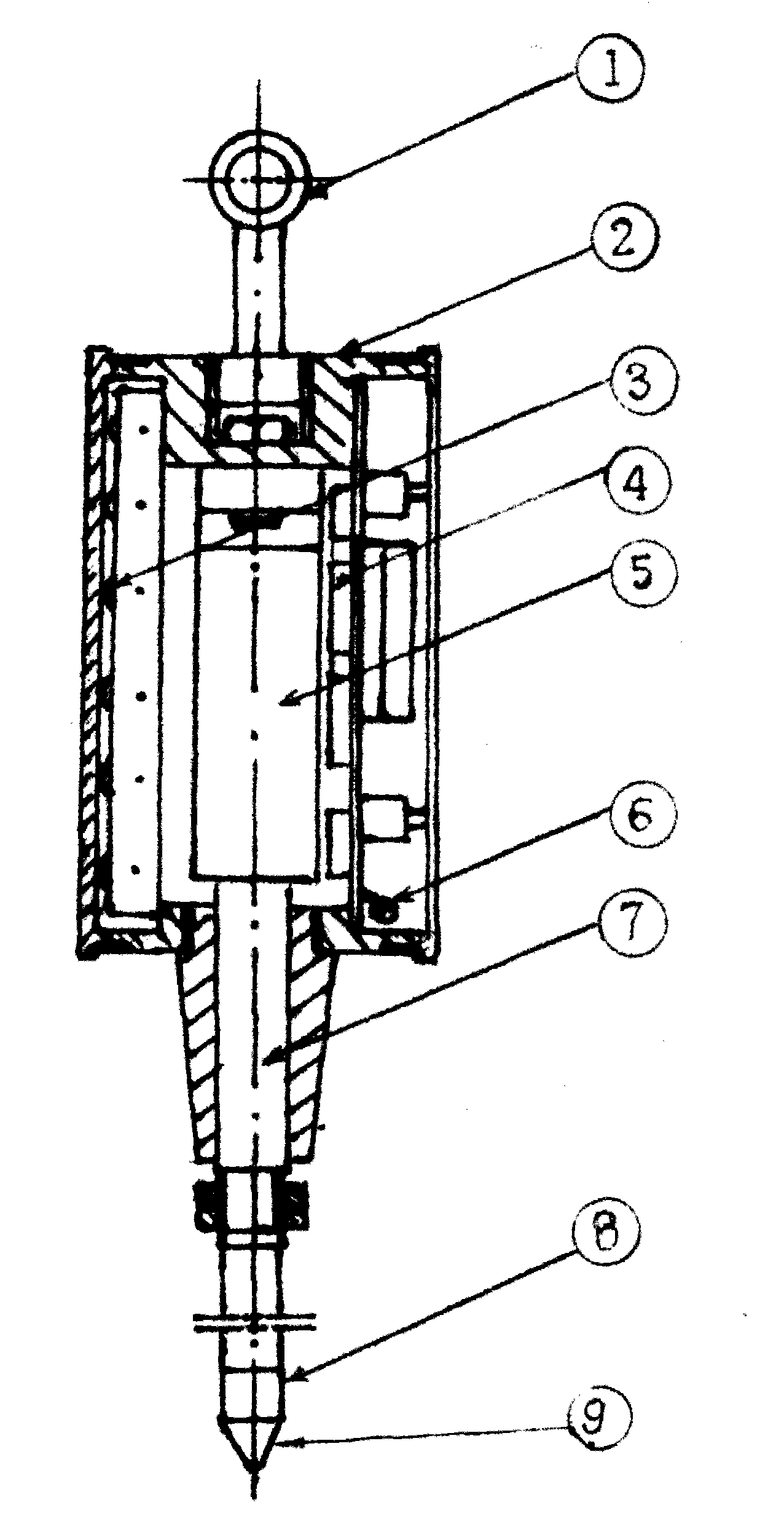

[0012] Fig. 1 is an embodiment of the present design invention: a special casing 2; Load sensor 5; Combine with mechanical conduction system (transmission shaft 7, probe rod 8, probe 9) and data acquisition processor 4 systematically Together, its features: the top of the casing is equipped with a T-shaped beam, the center of the inner cavity of the casing is fixed with a load sensor, the bottom of the casing is equipped with a displacement transmission shaft, and the casing is equipped with a data acquisition processor and a power box. , There is a communication interface outside the casing. The load sensor is connected with the transmission shaft, and then connected with the probe rod and the probe in turn.

[0013] The penetrating rod in Figure 1 is designed as a single-section or multi-section structure according to the detection needs, and the sections are connected by threads, keyways, and nails.

[0014] The contact probe in Fig. 1, its shape is designed as conical, py...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com