Processing method of soy protein and product thereof

A technology of soybean protein and processing method, which is applied in the direction of protein food ingredients, protein composition of vegetable seeds, food preparation, etc., to achieve technological progress, wide industrial application value, and good product efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

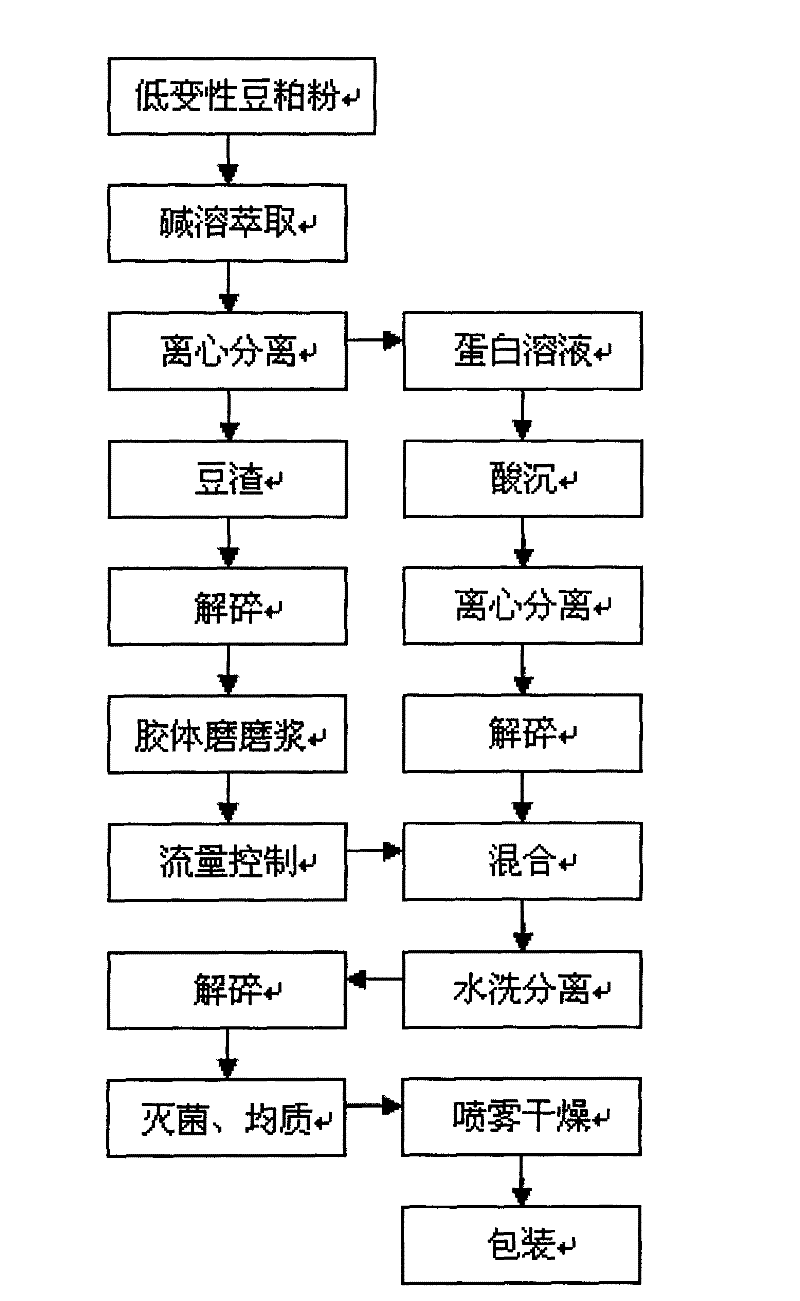

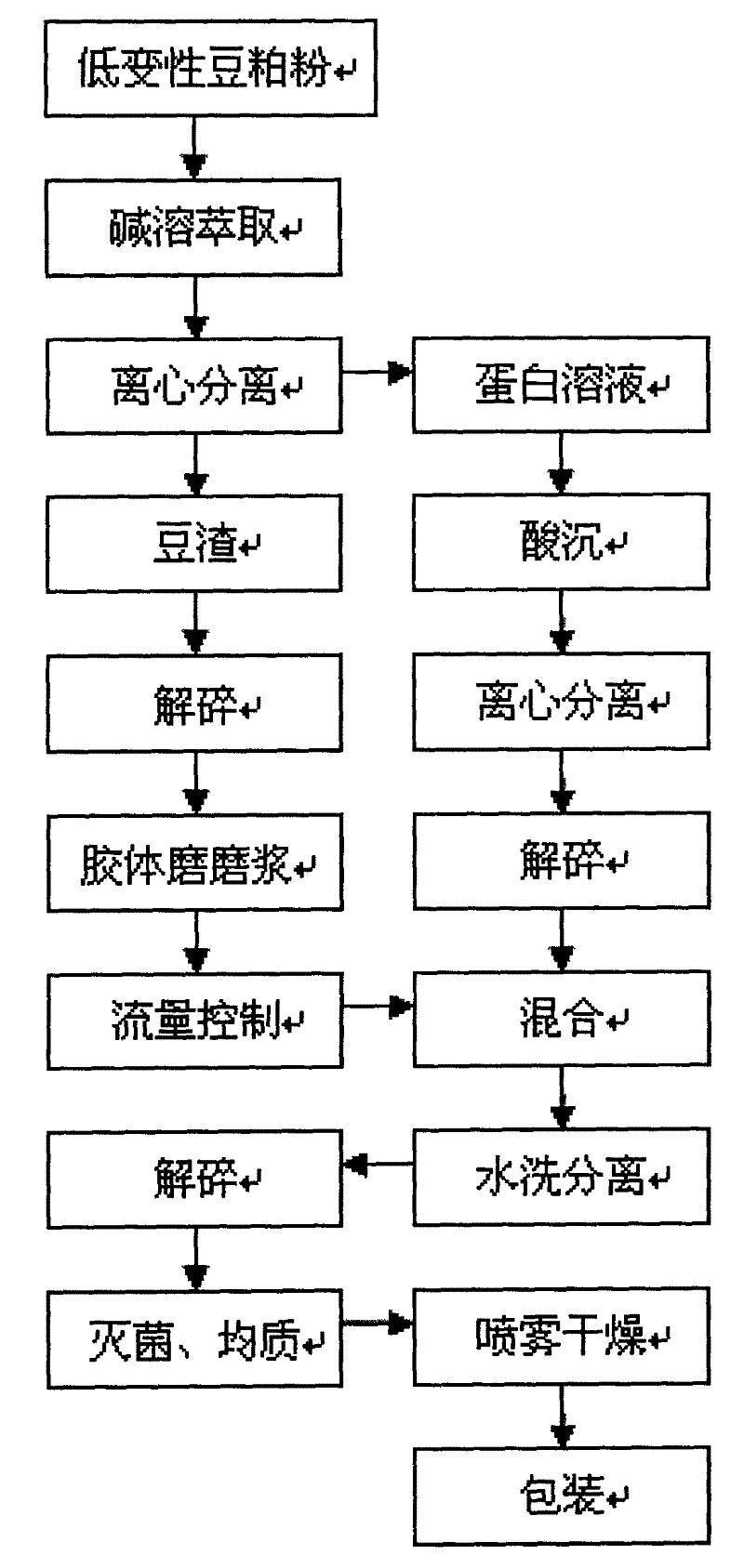

Image

Examples

Embodiment 1

[0038] Step 1: Transport the crushed low-temperature defatted soybean meal to the extraction tank, add 8 times the mass of water, adjust the pH to 7.0 with lye for extraction, the stirring speed is 90r / min, the temperature is controlled at 40°C, and the extraction time is 45min. The extract and bean dregs are pumped to a horizontal centrifuge for centrifugal separation, the separated protein solution is sent to a mixing soymilk tank, and the bean dregs enters an extraction storage tank.

[0039] Step 2: Pump the soymilk in the mixed soymilk tank into the acid sinking tank, add hydrochloric acid solution at 45°C and stir at 60r / min, and when the pH is adjusted to 4.2, let it stand for 30min to precipitate the protein. The precipitated protein and whey are transported to a horizontal centrifuge with a screw pump to separate the whey and protein curd, and the separated protein curd is ground and broken by adding water. At the same time, the bean dregs in the extraction storage ta...

Embodiment 2

[0044] Step 1: Transport the crushed low-temperature defatted soybean meal to the extraction tank, add 8.5 times the mass of water, adjust the pH to 7.2 with lye for extraction, the stirring speed is 90r / min, the temperature is controlled at 43°C, and the extraction time is 50min. The extract and bean dregs are pumped to a horizontal centrifuge for centrifugal separation, the separated protein solution is sent to a mixing soymilk tank, and the bean dregs enters an extraction storage tank.

[0045] Step 2: Pump the soymilk in the mixed soymilk tank into the acid sinking tank, add hydrochloric acid solution at 45°C, and stir at 65r / min, and when the pH is adjusted to 4.4, let it stand for 30min to precipitate the protein. The precipitated protein and whey are transported to a horizontal centrifuge with a screw pump to separate the whey and protein curd, and the separated protein curd is ground and broken by adding water. At the same time, the bean dregs in the extraction storage...

Embodiment 3

[0050] Step 1: Transport the pulverized low-temperature defatted soybean meal to the extraction tank, add 9 times the mass of water, adjust the pH to 7.4 with lye for extraction, the stirring speed is 90r / min, the temperature is controlled at 45°C, and the extraction time is 55min. The extract and bean dregs are pumped to a horizontal centrifuge for centrifugal separation, the separated protein solution is sent to a mixing soymilk tank, and the bean dregs enters an extraction storage tank.

[0051] Step 2: Pump the soymilk in the mixed soymilk tank into the acid sinking tank, add hydrochloric acid solution at 45°C and stir at 65r / min, and when the pH is adjusted to 4.4, let it stand for 30min to precipitate the protein. The precipitated protein and whey are transported to a horizontal centrifuge with a screw pump to separate the whey and protein curd, and the separated protein curd is ground and broken by adding water. At the same time, the bean dregs in the extraction storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com