Pressure soymilk grinder and pressure soymilk boiling method

A soymilk machine and pressure technology, applied in beverage preparation devices, household utensils, food science, etc., can solve the problems of poor taste, inconvenient cleaning, and complex structure of boiled milk, and achieve the effects of inhibiting loss, convenient cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

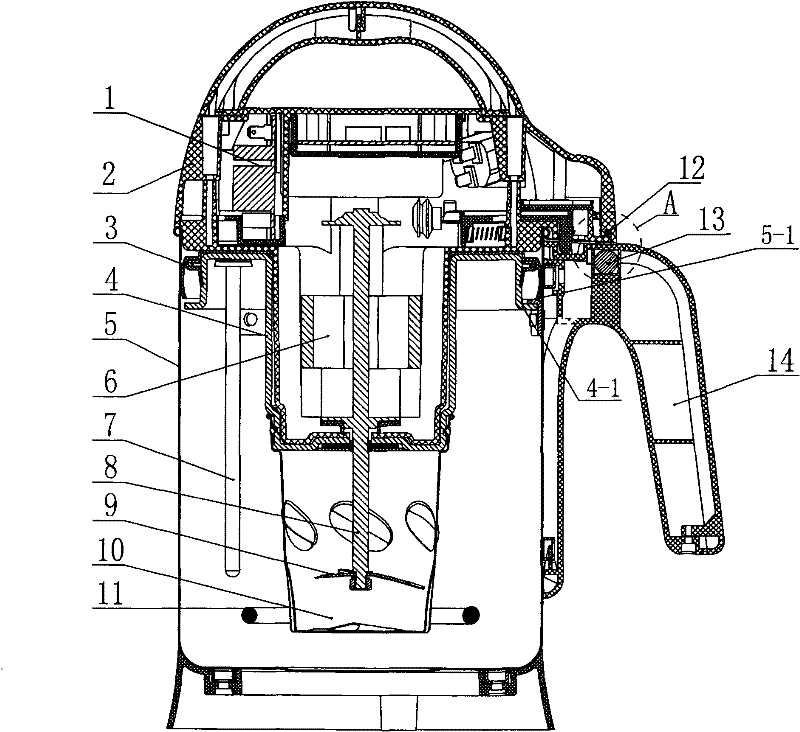

[0030] as attached figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 As shown, this pressure soybean milk machine is an embodiment of the motor top-mounted type, which consists of two parts: the machine base and the feeding cup;

[0031] The base part includes an electric control circuit board 1, a machine cover 2, a sealing ring 3, an inner cover of the base 4, a motor 6, a temperature sensor 7, a cutter shaft 8, a cutter 9, a net cover 10, a heater 11, and a reed Pipe 12, opening guide plate 21, conductive electrode 22, opening guide plate connecting rod 25, opening valve 26 and pressure limiting valve 27

[0032] The electric control circuit board 1 in the machine base is electrically connected with the motor 6, the heater 11, the reed switch 12, and the temperature sensor 7 respectively, so as to realize various signal detection and circuit control. Realize automatic refining, heating control, automatic induction chamber pressure function, and overpressure automa...

Embodiment 2

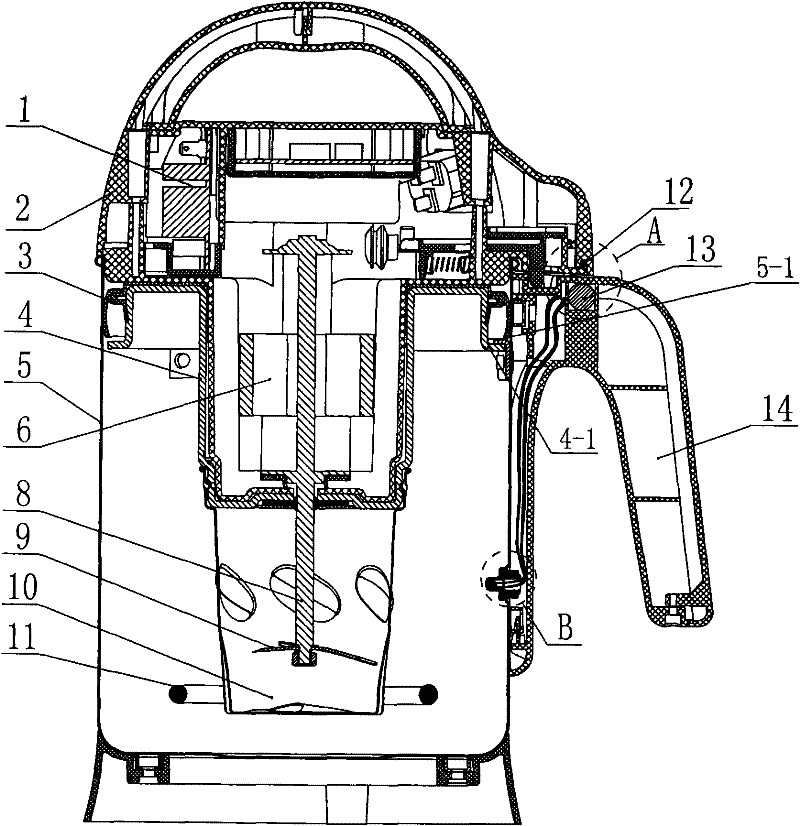

[0041] as attached Figure 2-Figure 7 As shown, the main structure and working principle of this pressure soybean milk machine are basically the same as that of Embodiment 1. The difference is that the temperature sensor of the second embodiment is arranged on the side wall of the cup body, and the electrical connection depends on the electrodes arranged on the handle and the machine. The electrodes on the seat are electrically connected.

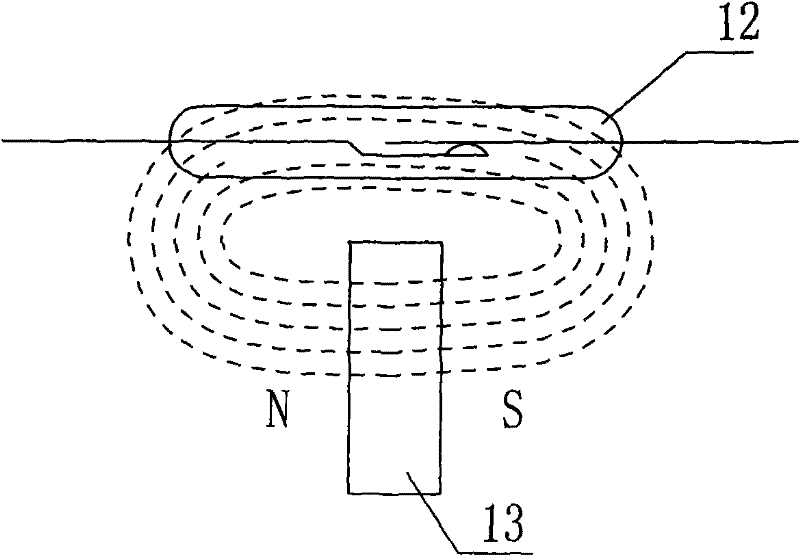

[0042] as attached figure 2 , Figure 5 , Figure 4 As shown, the feed cup is composed of feed cup 5, magnet 13, and handle 14. A guide rod chute 23 is arranged on the top of the handle 14, and a magnet 13 is arranged inside the handle. The placement direction of the magnet 13 can be horizontal or vertical; The temperature sensor on the side wall of the cup body consists of a temperature sensing cover sealing ring 15, a temperature sensing cover 16, a temperature sensing cover front end 17, a heat conducting grease 18, a thermistor 19 (...

Embodiment 3

[0047] as attached Figure 8 As shown, the lower part of the material cup is provided with a buckle frame 32. The bottom of the buckle frame 32 is an elastic body 33, which is placed on the bottom surface of the material cup. The upper part of the buckle frame 32 is connected to a rigid buckle 30 through a rotating shaft 31, and the buckle is fastened to the top surface of the machine base. Shoulder 29, the displacement end of elastic body is provided with tact switch.

[0048] A pressure-bearing shoulder 29 is set inside the machine base, and the top of the pressure-bearing shoulder 29 is the horizontal crimping part 28 of the rigid buckle 30. The buckle frame 32 can be symmetrical to both sides of the material cup 5, and multiple rigid buckles 30 can be rotated. Buckle the top of the shoulder 29 on the top surface of the machine seat. An electric heating plate for electric heating is arranged between the bead and the bottom of the material cup. When the electric heating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com