Preparation method of composite silica aerogel

A silica and aerogel technology, applied in the field of aerogel, can solve the problems of unsatisfactory pore distribution and particle size of aerogel, and achieve the effects of low cost, simple operation and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

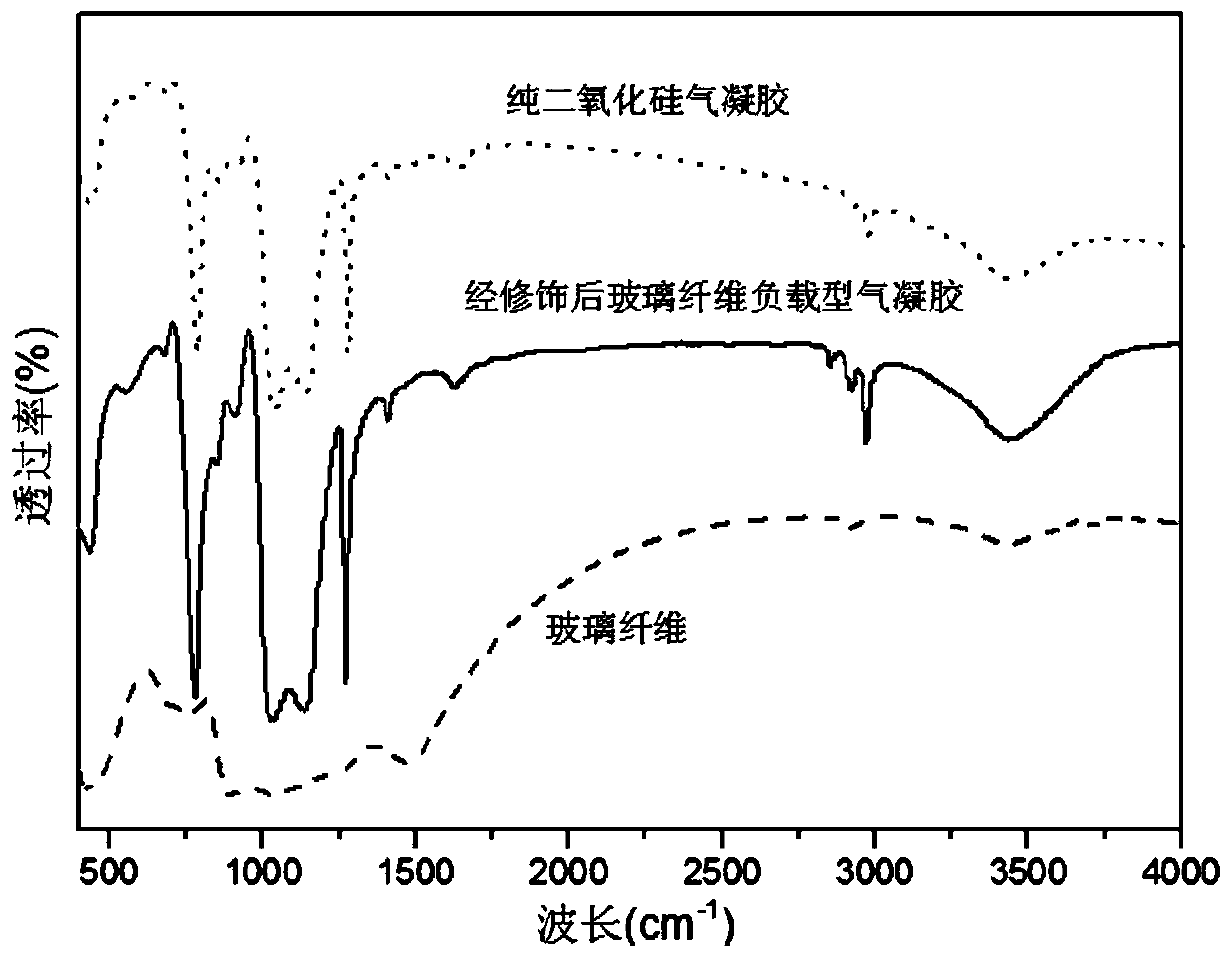

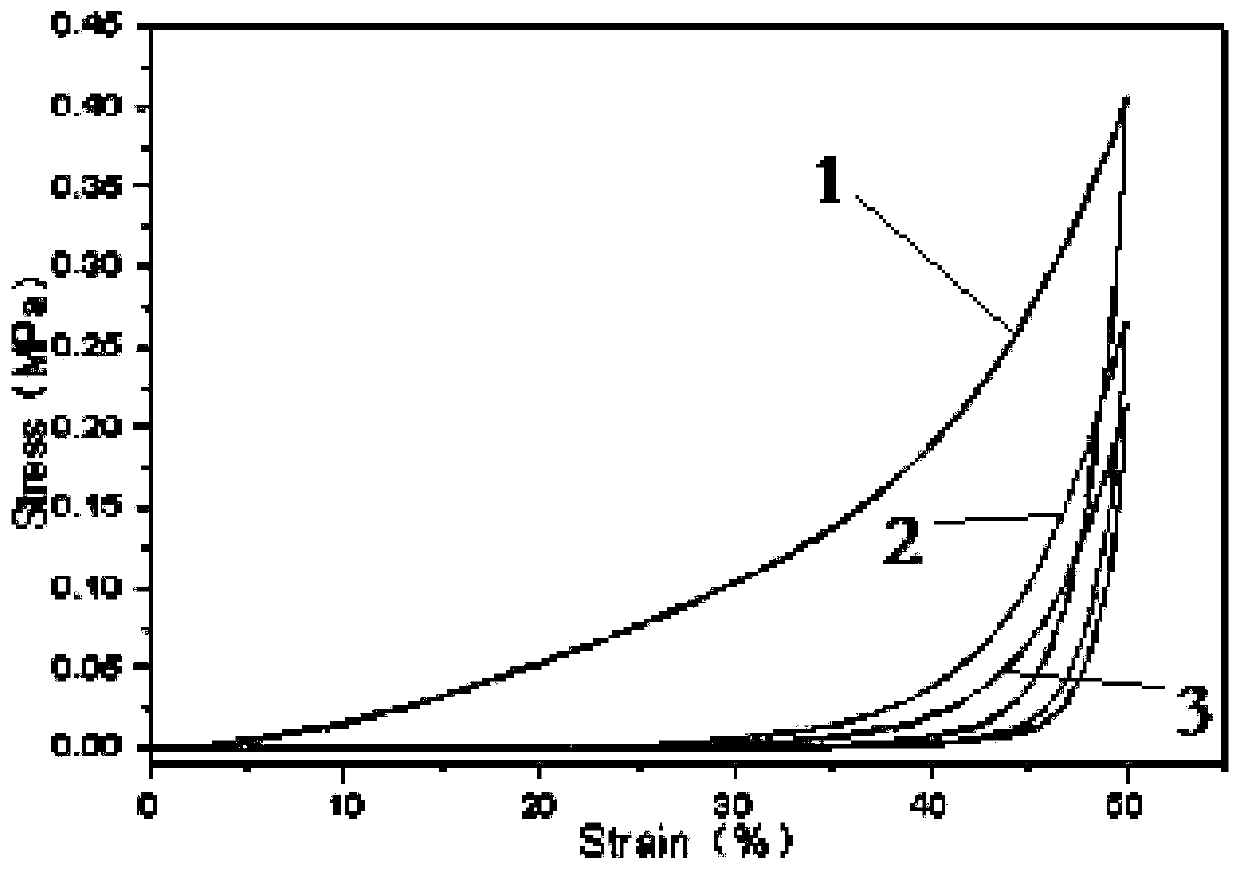

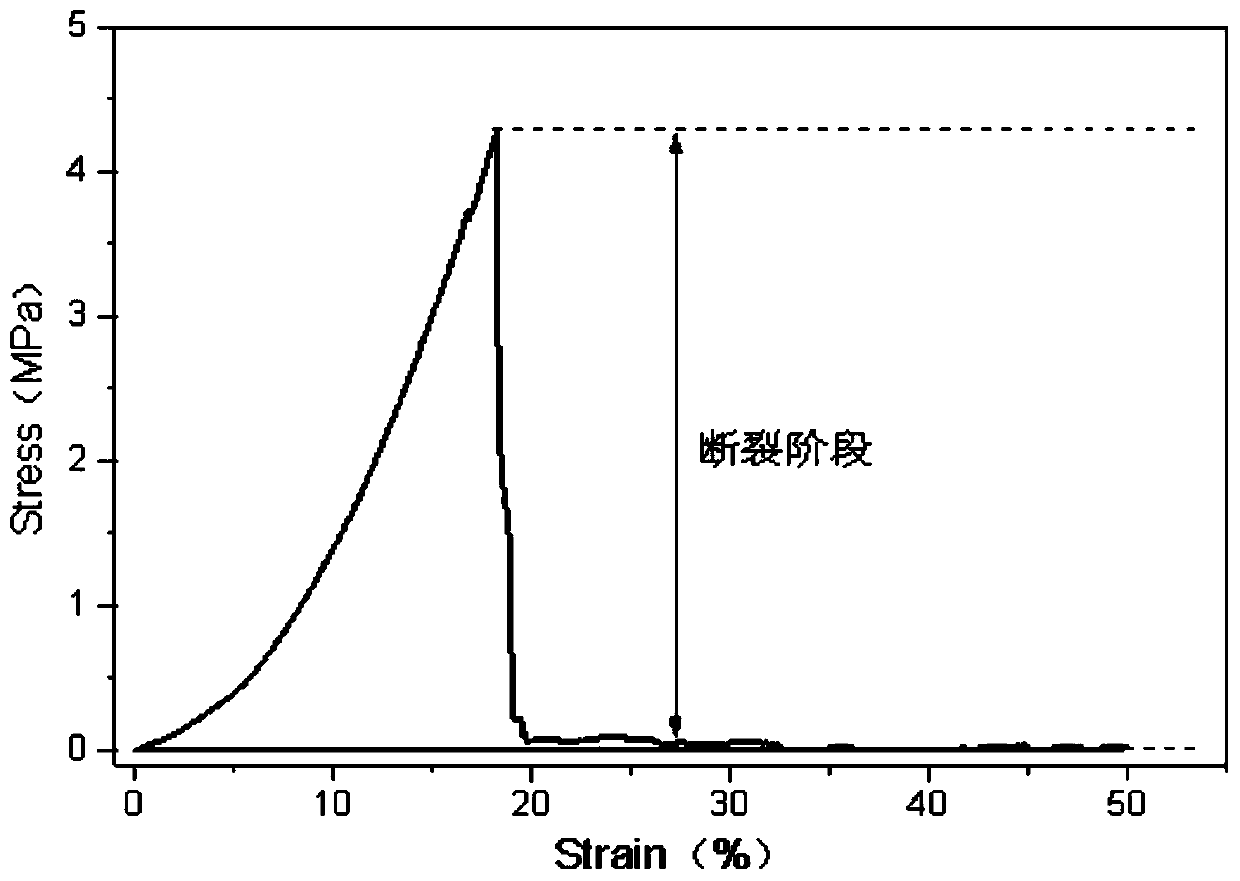

Embodiment 1

[0032] After washing the glass fibers, put them in an oven at 150°C for 12 hours to remove the remaining substances of the fibers and perform fluffing treatment. MTMS (methyltrimethoxysilane) with a total mass of 0.08g, H 2 O, hydrochloric acid aqueous solution and cationic detergent CTAB are added to the beaker, and a certain amount of glass fiber is added to mix and stir evenly. Adjust the pH between 3-4, stir and hydrolyze at 30°C for 1 hour, add 0.5 mol / L ammonia solution and stir for 5 minutes, then gel in ultrasonic to ensure that the fiber layer is evenly distributed until a wet gel is formed. The wet gel was soaked in a mixed solution of ethanol and n-hexane with a volume ratio of 1:1, aged and replaced in an oven at 60°C for 12 hours. Modified with a mixed solution of TMCS and n-hexane solution, and modified in an oven at 55-60°C for 12h. The modified wet gel was immersed in n-hexane, rinsed, and dried at 80°C for 10 hours, at 120°C for 2 hours, and at 150°C for 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com