Sealing method of steel-frame reinforced plastic composite pipe

A technology for reinforced plastic and composite pipes, applied in the field of plastic pipe processing, can solve the problems of difficult sealing quality, high production cost, cumbersome operation, etc., and achieve the effect of reducing personnel and equipment, reducing sealing cost and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

[0017] The steel frame reinforced plastic composite pipe sealing method comprises the following steps:

[0018] ① Clean the heating plate with a clean cotton fabric;

[0019] ② Grind the end face of the pipe with an electric angle grinder to remove the oxide layer;

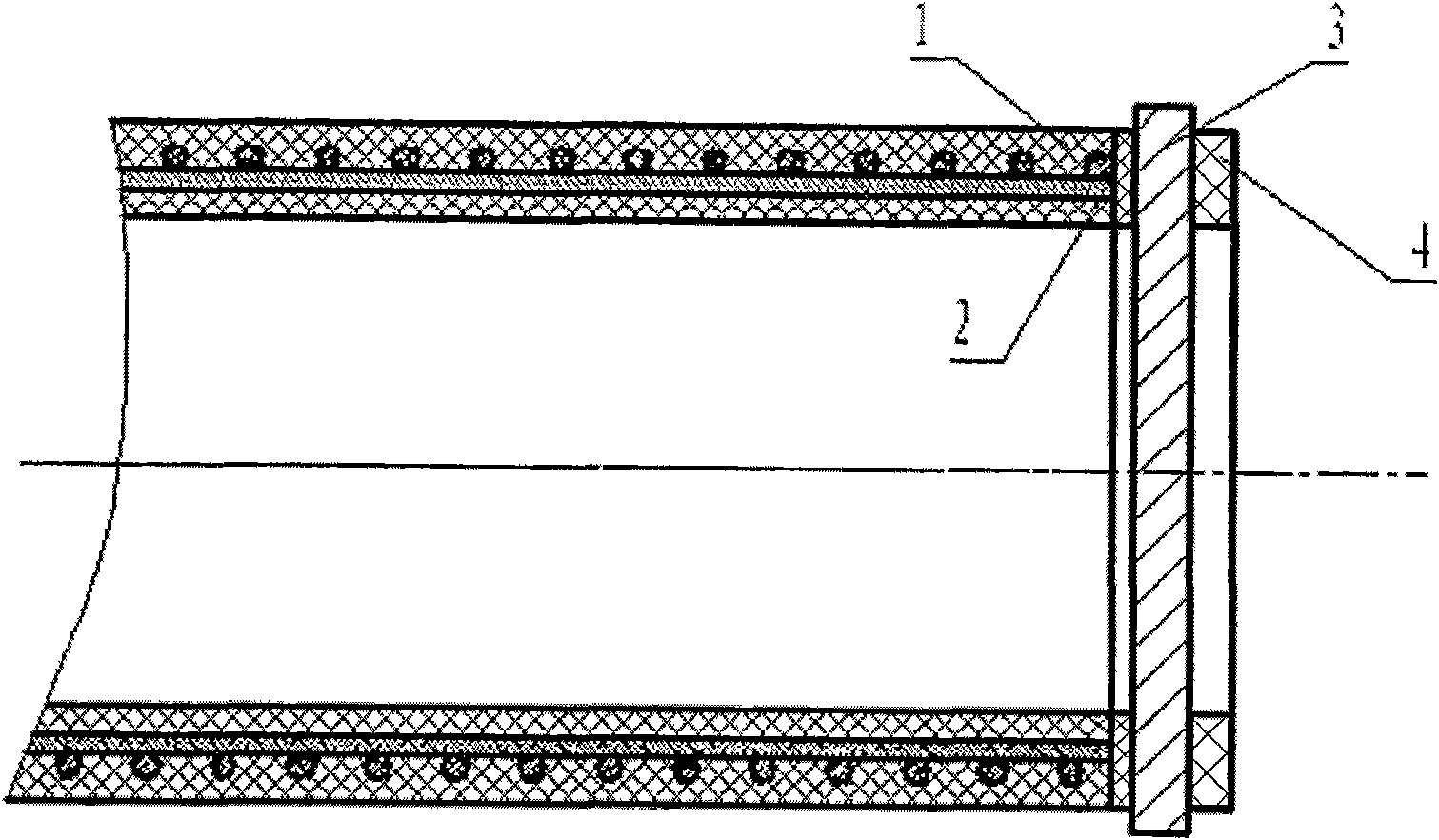

[0020] ③Tighten the pipe 1, plastic preheating ring 2, and plastic sealing ring 4 on the welding machine at the same time, and keep the end faces aligned;

[0021] ④ Use a milling cutter to mill the end face of the pipe to be melted and the end face of the sealing ring, and start welding immediately after milling;

[0022] ⑤ Install the heating plate 3 between the plastic preheating ring 2 and the plastic sealing ring 4, make the end faces of the plastic preheating ring 2 and the plastic sealing ring 4 stick to the heating plate, and apply a pressure of 0.15MP;

[0023] ⑥Heat the heating plate 3. The temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com