Novel process for pretreating carbendazim wastewater

A carbendazim and new process technology, which is applied in the new process field of pretreatment of carbendazim pesticide production wastewater, can solve problems such as incomplete sedimentation and centrifugation, high ammonia nitrogen concentration, and increased difficulty in biochemical treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

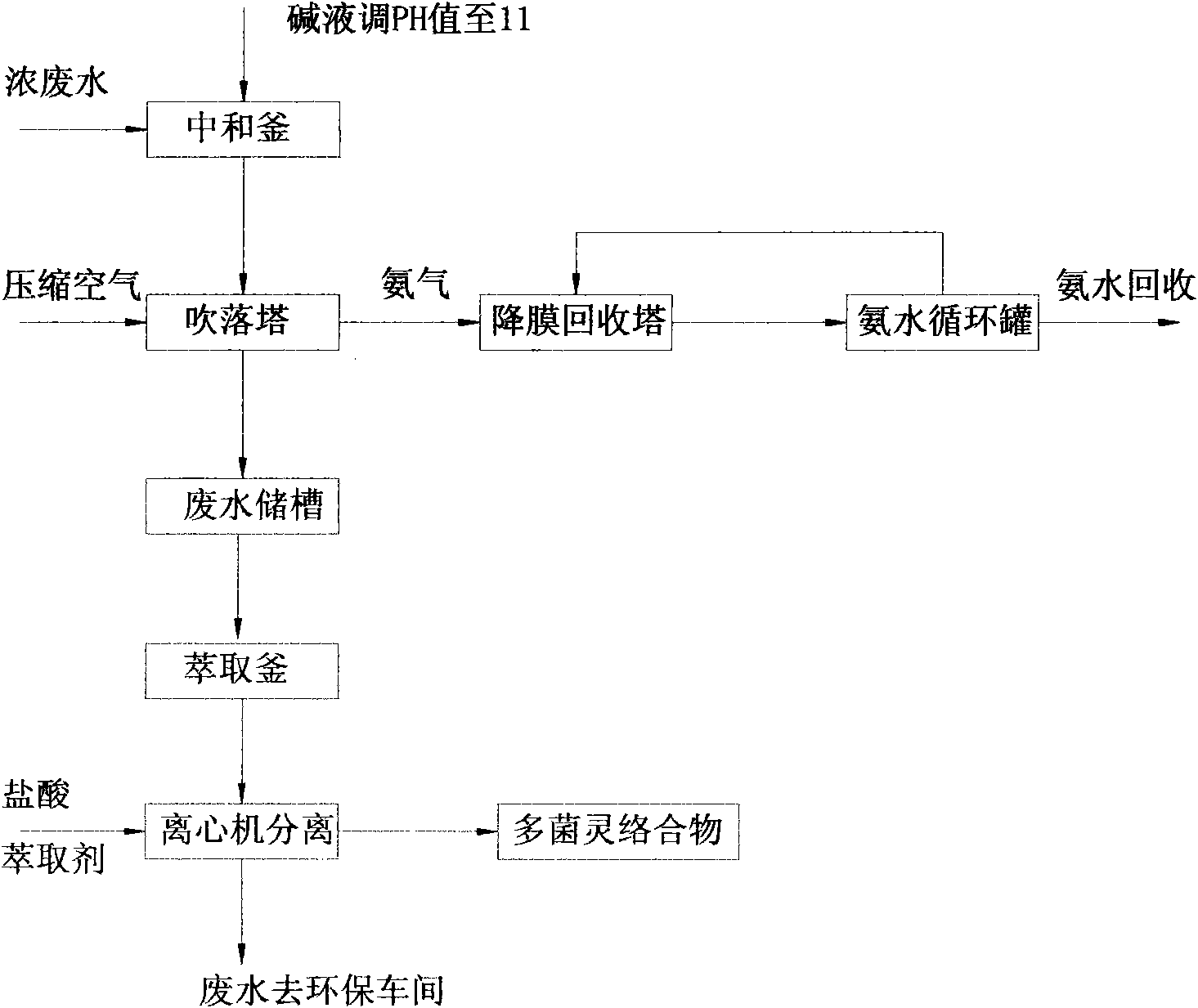

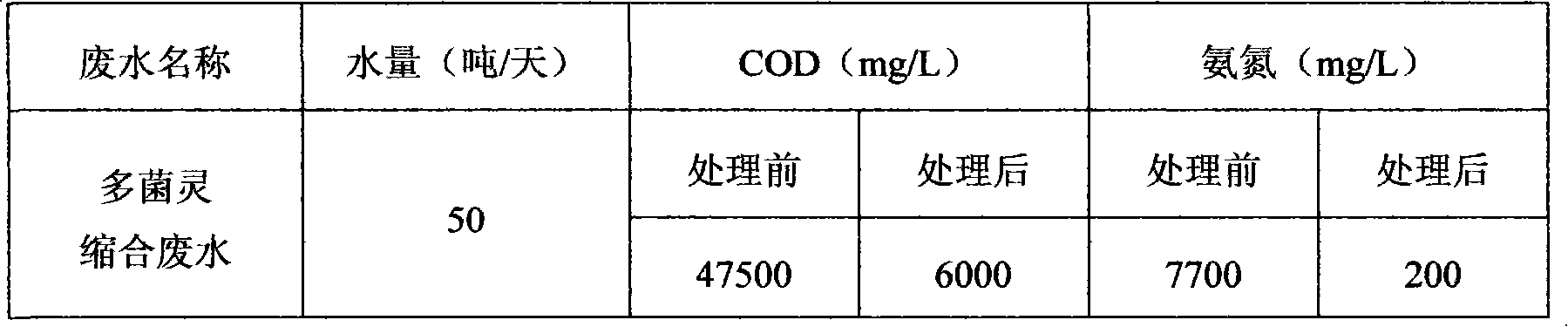

[0005] see figure 1 , the treatment process of the present invention mainly adopts the following process steps: 1, adjust the pH value to 11 in the neutralization tank with lye for concentrated waste water; 2, utilize compressed air to blow out ammonia in the stripping tower; 3, blow ammonia 4. Put the remaining waste water into the waste water storage tank; 5. Then put the waste water into the extraction kettle and extract it with hydrochloric acid and extractant; 6. Finally, use a centrifuge to separate the solid Carbendazim complex; 7. Wastewater is sent to the environmental protection workshop for biochemical treatment. After being treated by the new process of the invention, the color of the waste water becomes lighter, and the biochemical property is obviously improved, and it is transported to the environmental protection workshop through pipelines for biochemical treatment and discharged up to the standard. The solid carbendazim complex obtained in step 6 has medicina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com