Environment friendly metal forging mold-releasing agent

A release agent, an environmentally friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of clothing stains, damage to health, bronchitis and pneumoconiosis, etc., to achieve smooth forgings, prolong service life, reduce Effect of Die Wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

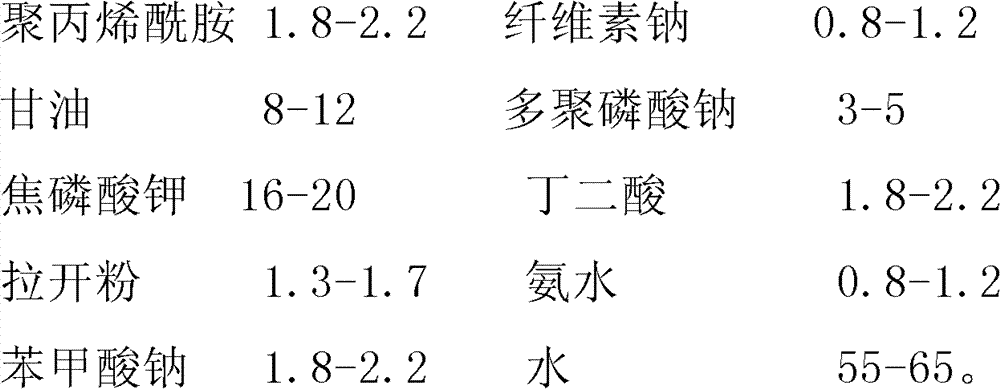

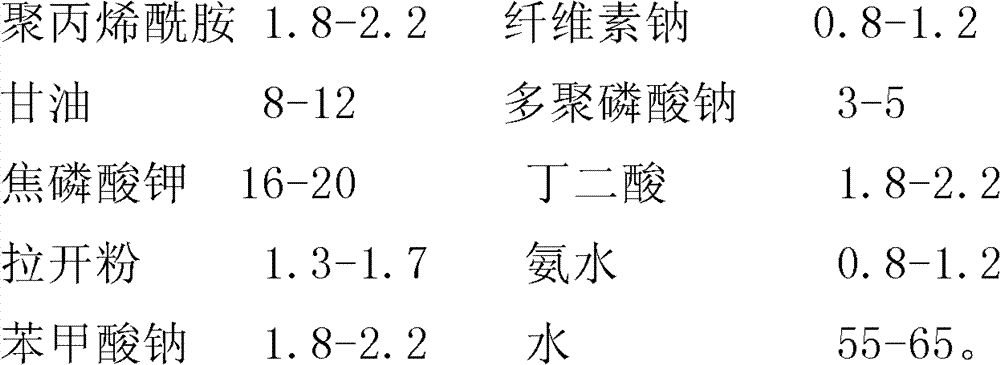

[0007] Take 2kg of polyacrylamide, 1kg of CMC-Na and 59.5kg of water, mix well, add 4kg of sodium polyphosphate, 18kg of potassium pyrophosphate, mix well, then add 1.5kg of pull-off powder, 10kg of glycerin, and 2kg of succinic acid, After mixing, add 1 kg of sodium benzoate and 1 kg of ammonia water, and grind with a colloid mill to obtain the finished product. Appearance: Light yellow translucent liquid; Relative density: 1.03; Viscosity: 9±2s; Suspension (1:4): 95%; PH value: 9.

[0008] Technical performance:

[0009] (1) According to the size, weight and shape of the forging body, it has good lubricity under high temperature conditions. For the die forging process of large forging molds without ejector devices, one spray can be used for multiple impact molding.

[0010] (2) It has a good heat insulation and cooling effect on the mold, and has excellent resistance to hot pressure, which can reduce mold wear and prolong the service life of the mold.

[0011] (3) Under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com