Sustained arc high energy electrostatic igniter and control method thereof

An igniter, continuous arc technology, applied in the continuous arc high-energy electrostatic igniter and its control field, can solve the problems of high cost consumption, hidden safety hazards, unsafe use and transportation, etc., and achieve the effect of improving ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

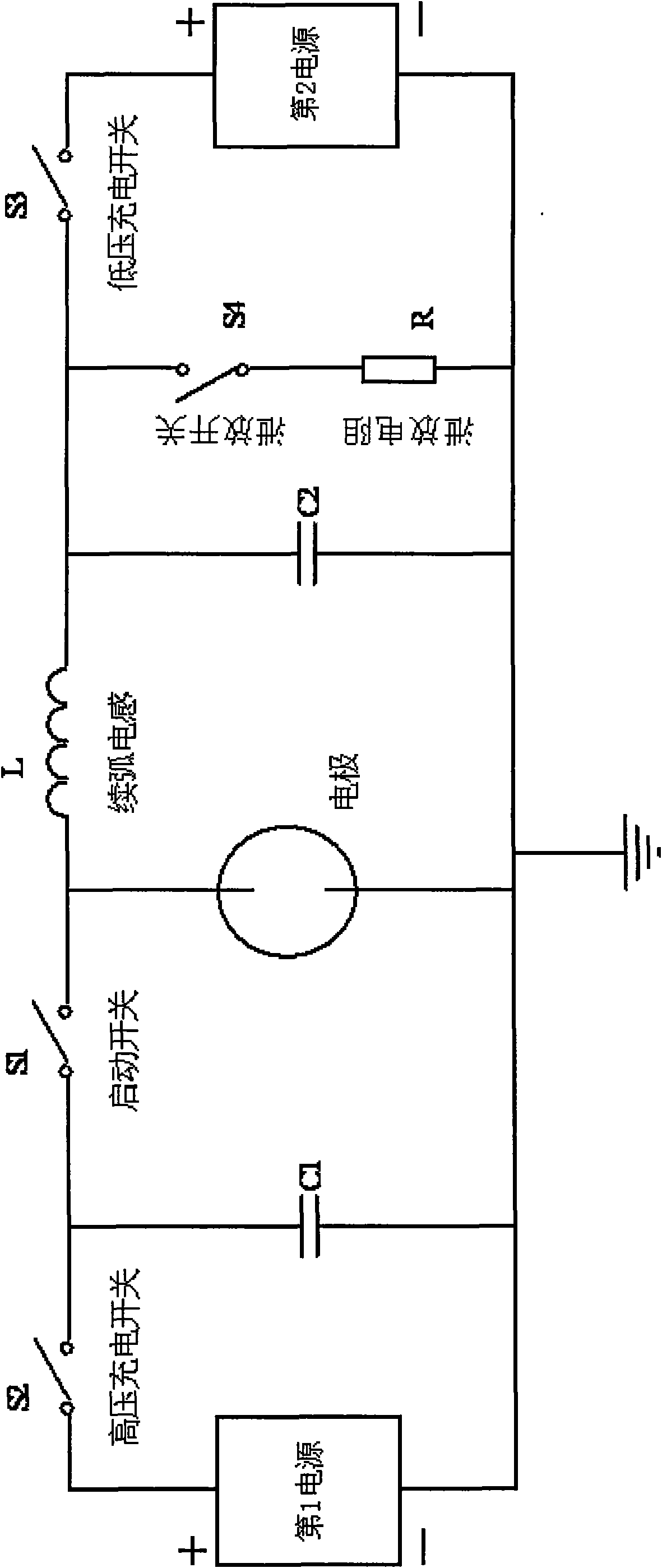

[0030] The arc-continuing high-energy electrostatic igniter is integrated in the dust cloud minimum ignition energy test system as the ignition source of the dust cloud. The system consists of explosive device, PLC control system, touch screen man-machine interface, upper computer PC and electrostatic ignition system. Install the electrode end of the continuous arc high-energy electrostatic igniter on the 20L spherical explosive device. During the ignition process, electric sparks will be generated in the 20L spherical explosive device, releasing huge energy and emitting strong light.

[0031] image 3 It is the circuit schematic diagram of the continuous arc type high-energy electrostatic igniter of the present embodiment. It is mainly composed of charging circuit, ignition circuit, continuous arc circuit and discharge circuit.

[0032] The charging circuit includes a first power source and a second power source. The first power supply charges the high-voltage capacitor C1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com