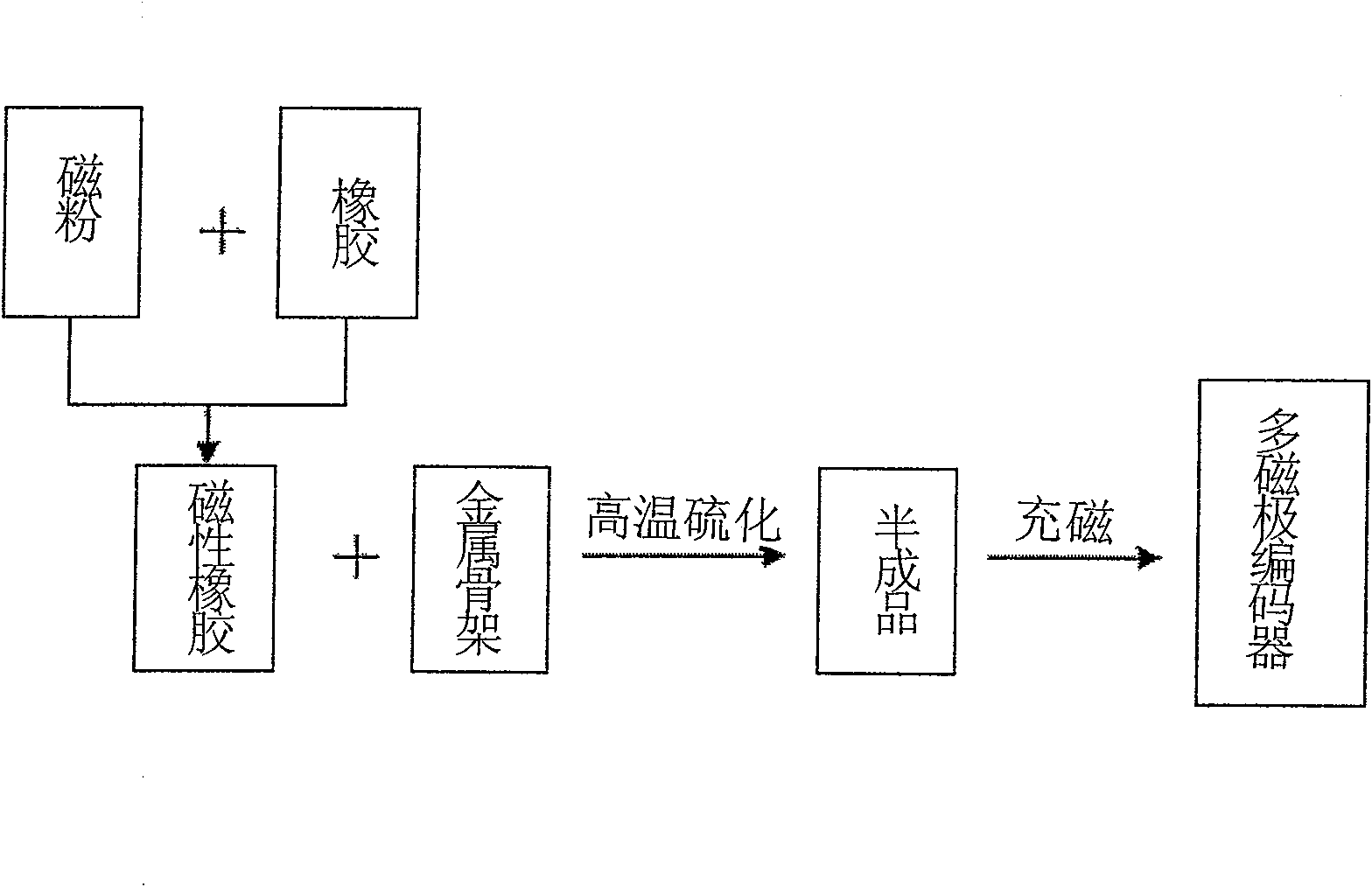

Process for manufacturing multi-polar magnetic coder

A magnetic encoder and manufacturing process technology, which are applied to devices using electric/magnetic methods, and use electric/magnetic devices to transmit sensing components, etc., can solve the problems of large volume, inelastic product shape, singleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] In order to achieve a magnetic encoder with a high electromagnetic signal, it is necessary to choose a suitable magnetic powder material. The magnetism of magnetic powder depends on the type of magnetic powder; the magnetic properties of the same type of magnetic powder depend on the crystal structure, mainly crystal shape, particle size and uniformity; magnetic powder mainly includes metal magnetic powder and ferrite magnetic powder. And the reason of the price, the actual application is less, mainly use the ferrite magnetic powder. Ferrites with better performance include cobalt ferrite, strontium ferrite, barium ferrite and iron ferrite; the magnetic properties of cobalt ferrite are better than barium ferrite and strontium ferrite, but cobalt ferrite Ferrite is expensive, has poor thermal stability and magnetic retention, and is rarely used in practical applications. After a lot of experiments, we found that strontium ferrite has the best overall performance. Magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com