Magnetic recording medium

a magnetic recording and recording drive technology, applied in the direction of magnets, instruments, other domestic objects, etc., can solve the problems of large coercive force, difficult to perfectly isolate the crystal grain of the ferromagnetic film, noise reduction and increase of noise, etc., to achieve noise reduction and high coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) Explanation of a method for manufacturing a magnetic recording medium according to the present invention:

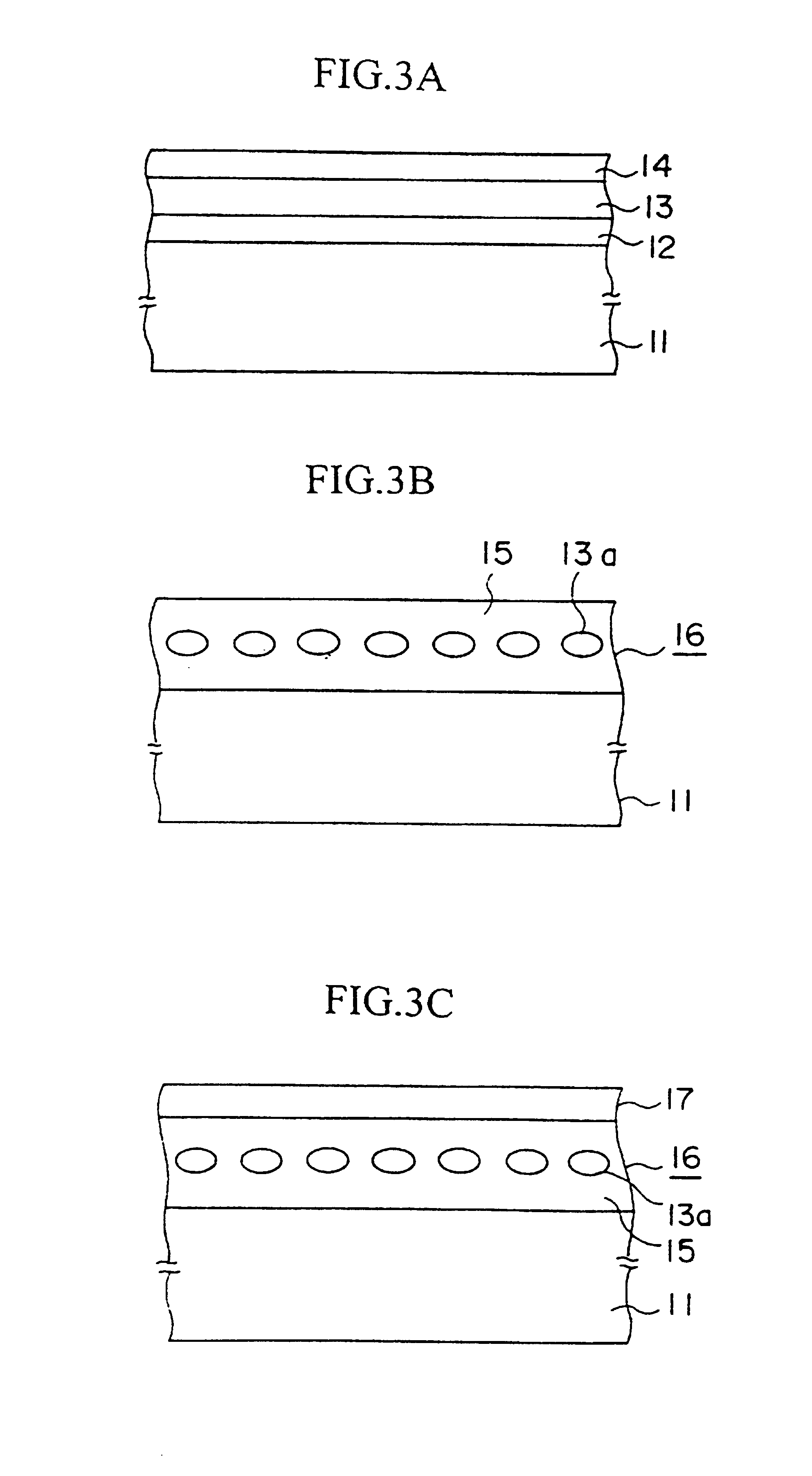

FIGS. 3A to 3C are sectional views showing a manufacturing method of the magnetic recording medium according to the first embodiment of the present invention.

First, as shown in FIG. 3A, a silver (Ag) film (nonmagnetic film) 12 having a film thickness of 5 nm is formed by sputtering on a silicon substrate (nonmagnetic substrate) 11 having a diameter of 2.5 inch, for example, under the conditions that argon pressure is 5 mTorr, a substrate temperature is 20.degree. C., a DC power is 0.2 kW, and a DC bias voltage is not applied.

Then, a cobalt (Co) film (ferromagnetic film) 13 of 7 nm in film thickness is formed on the silver film 12 by sputtering under the conditions that argon pressure is 5 mTorr, a substrate temperature is 20.degree. C., a DC power is 0.2 kW, and a DC bias voltage is not applied.

Subsequently, a silver (Ag) film 14 having a film thickness of 5 nm is formed on t...

second embodiment

(2) Explanation of a method for manufacturing a magnetic recording medium according to the present invention:

FIG. 5 is a sectional view showing a magnetic recording medium manufactured by a manufacturing method according to a second embodiment of the present invention. The second embodiment differs from the first embodiment in that a carbon film is used in place of the silver films between which the cobalt film is put. Also, since a carbon film 18 is utilized on the uppermost portion of the recording layer 19, the protection layer is shared with the carbon film 18 on the recording layer 19.

Referring to FIG. 5, the second embodiment of the present invention will be explained hereinafter.

First, a carbon film (nonmagnetic film) having a film thickness of 5 nm is formed by sputtering on a silicon substrate (nonmagnetic substrate) 11 under the conditions that argon pressure is 10 mTorr, a substrate temperature is 20.degree. C., an AC power having a frequency of 13.56 MHz is 0.2 kW, and a...

third embodiment

The third embodiment is different from the first and second embodiments in the respect that a Co.sub.90 Cr.sub.10 film may be used in place of the cobalt film as the ferromagnetic film sandwiched with the nonmagnetic films.

In comparison with the Co film, the crystal structures of crystal grains of the ferromagnetic film are readily formed as the hcp structures in the Co.sub.90 Cr.sub.10 film, because of existence of Cr therein. Thus, the Co.sub.90 Cr.sub.10 film has a feature that high coercive force can easily be obtained.

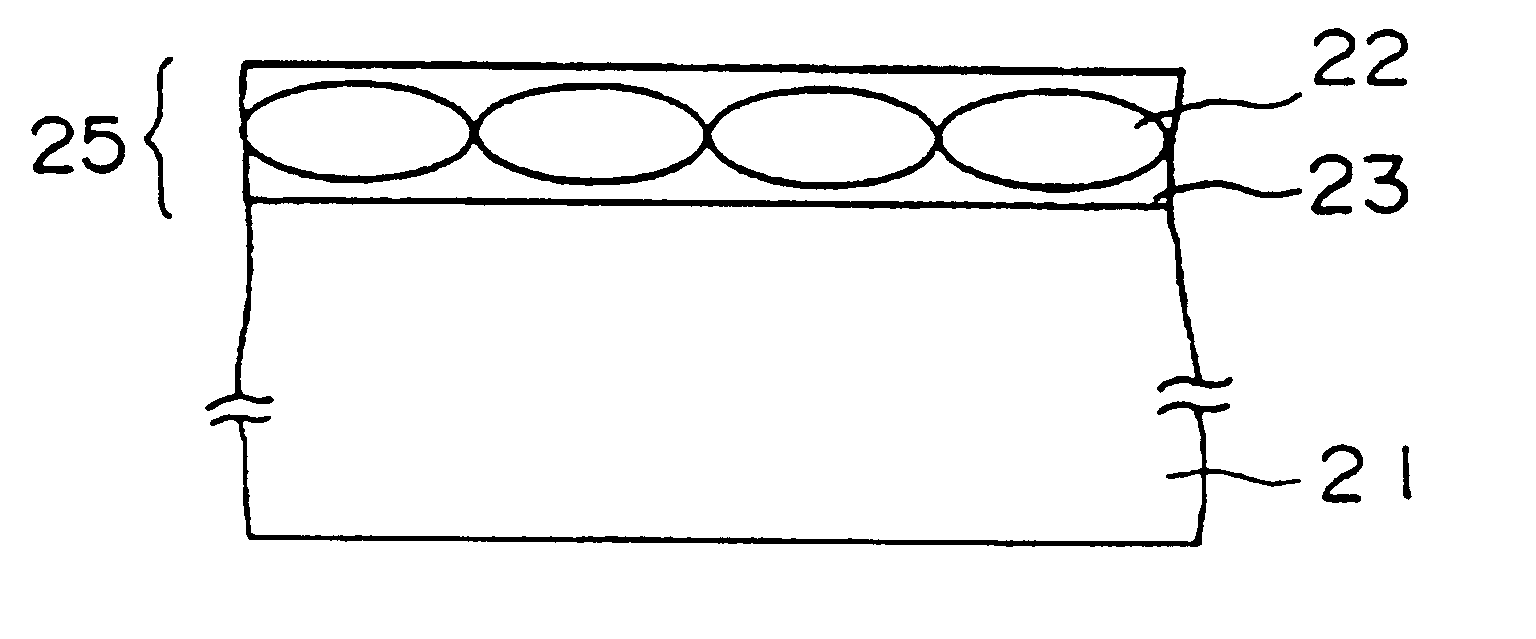

A film forming method is the same as that used for the Co film, which has been explained in the first and second embodiments. As a result, the recording layer 21 in which the crystal grains 13 of Co.sub.90 Cr.sub.10 are dispersed into the silver film 20 and mutual crystal grains 13c are perfectly isolated can be formed on the silicon substrate (nonmagnetic substrate) 11.

In this case, as shown in Table I above, assuming that noise power in the conventional example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| average grain diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com