Glass fiber tape film lapping aluminum circular transposition lead

A technology of glass ribbon and transposed wire, applied in the directions of quartz/glass/glass enamel, conductor, insulated conductor, etc., can solve the problem of less transposition times of transposed wire, large core gap of transposed wire, large eddy current and circulating current loss and other problems to achieve the effect of reducing quality, improving electrical performance, reducing eddy current and circulating current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

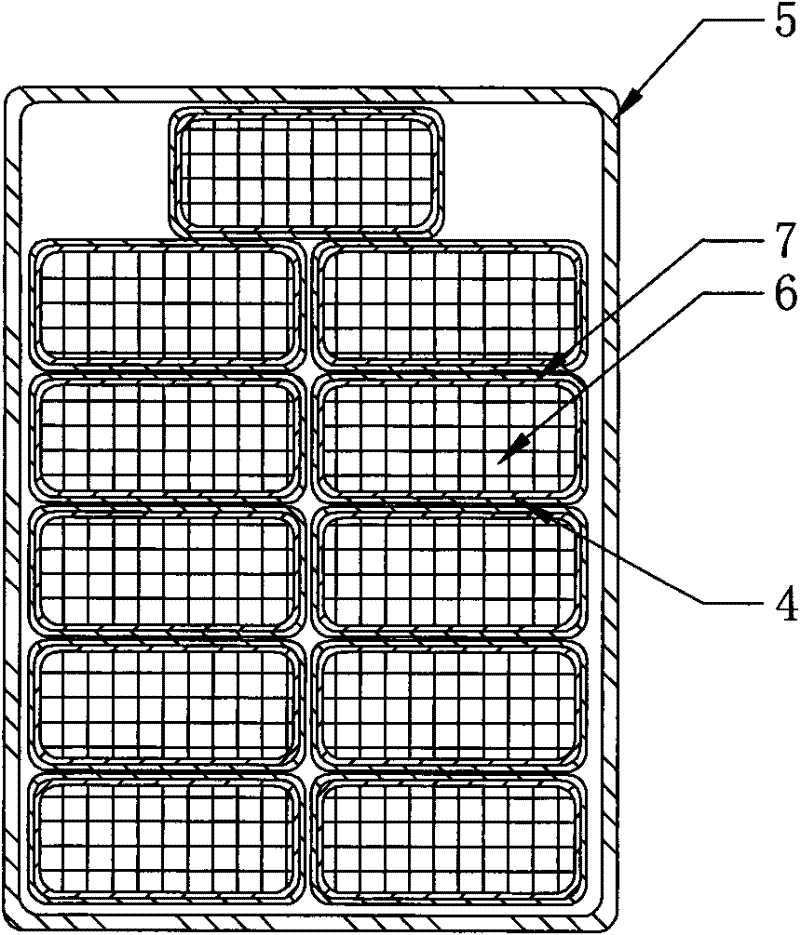

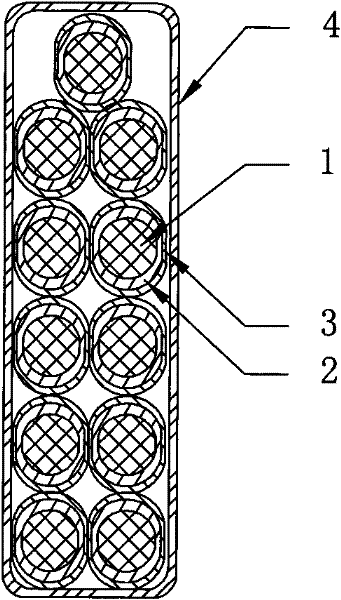

[0012] See image 3 , Figure 4 , the present invention includes a transposition wire core, the exterior of the transposition wire core is wrapped by an insulating layer 4, the transposition wire core is transposed into two rows by several film-wrapped wires, and the film-wrapped wire is a film-wrapped aluminum round wire, The insulating layer 4 is a glass ribbon, and the wrapping structure of the insulating layer 4 is that the outermost two layers of glass ribbons 5 and 6 are self-locking wrapping, and the remaining layers of glass ribbons are wrapping with opposite seams; the film-wrapped aluminum round conductor includes the aluminum round conductor 1, Aluminum round conductor 1 is wrapped with film 2; film 2 is coated with insulating varnish 3; film 2 is polyester film or polyimide film; insulating varnish 3 is epoxy self-adhesive varnish. When the aluminum round transposition wire wrapped with glass ribbon film of the present invention is applied to an outdoor environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com