Method for producing tungsten trioxide powder for photocatalyst, tungsten trioxide powder for photocatalyst, and photocatalyst product

一种光催化剂、三氧化钨的技术,应用在氧化钨/氢氧化钨、催化剂活化/制备、化学仪器和方法等方向,能够解决制造效率低等问题,达到粒径分布窄、优异光催化性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

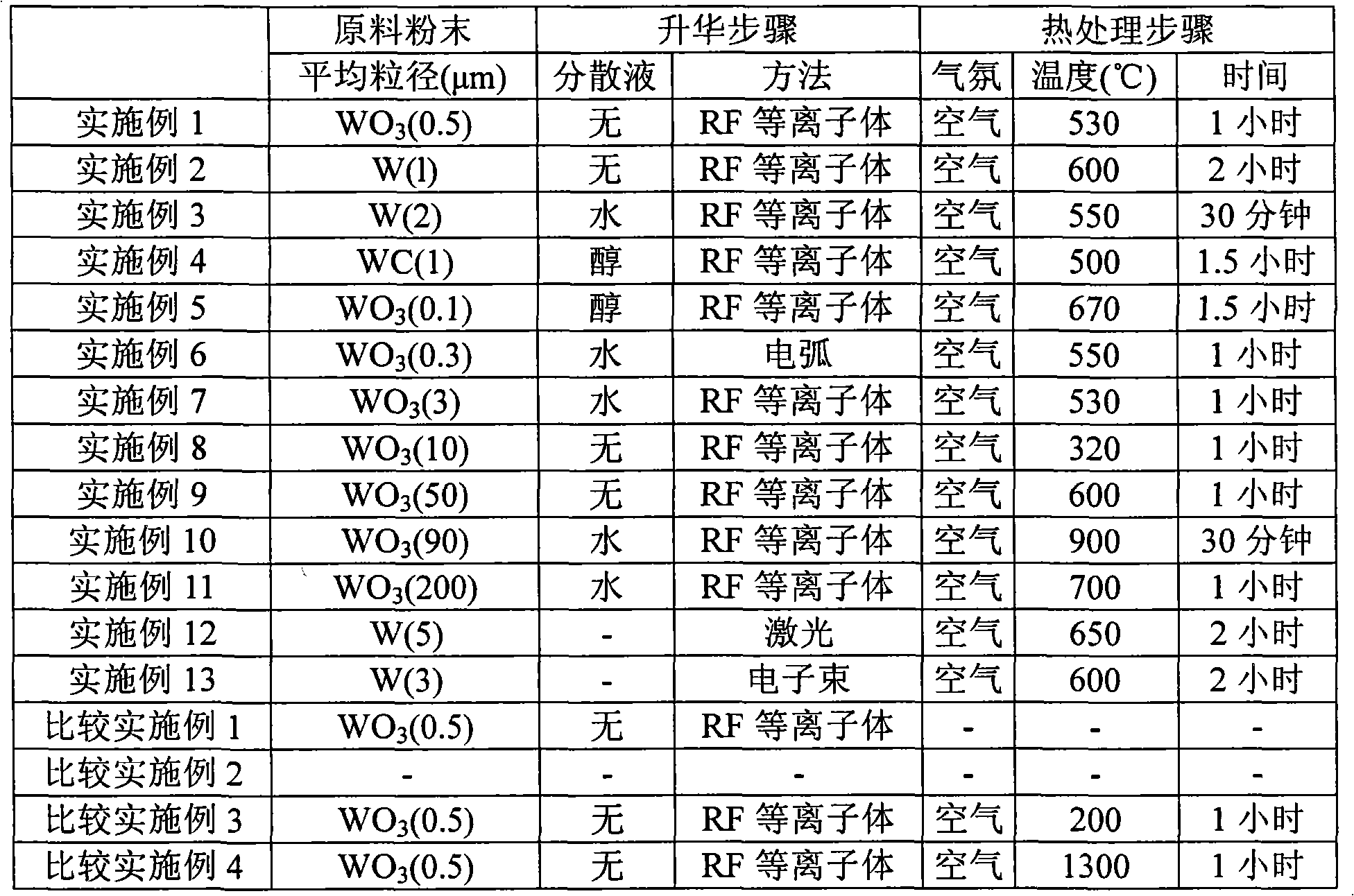

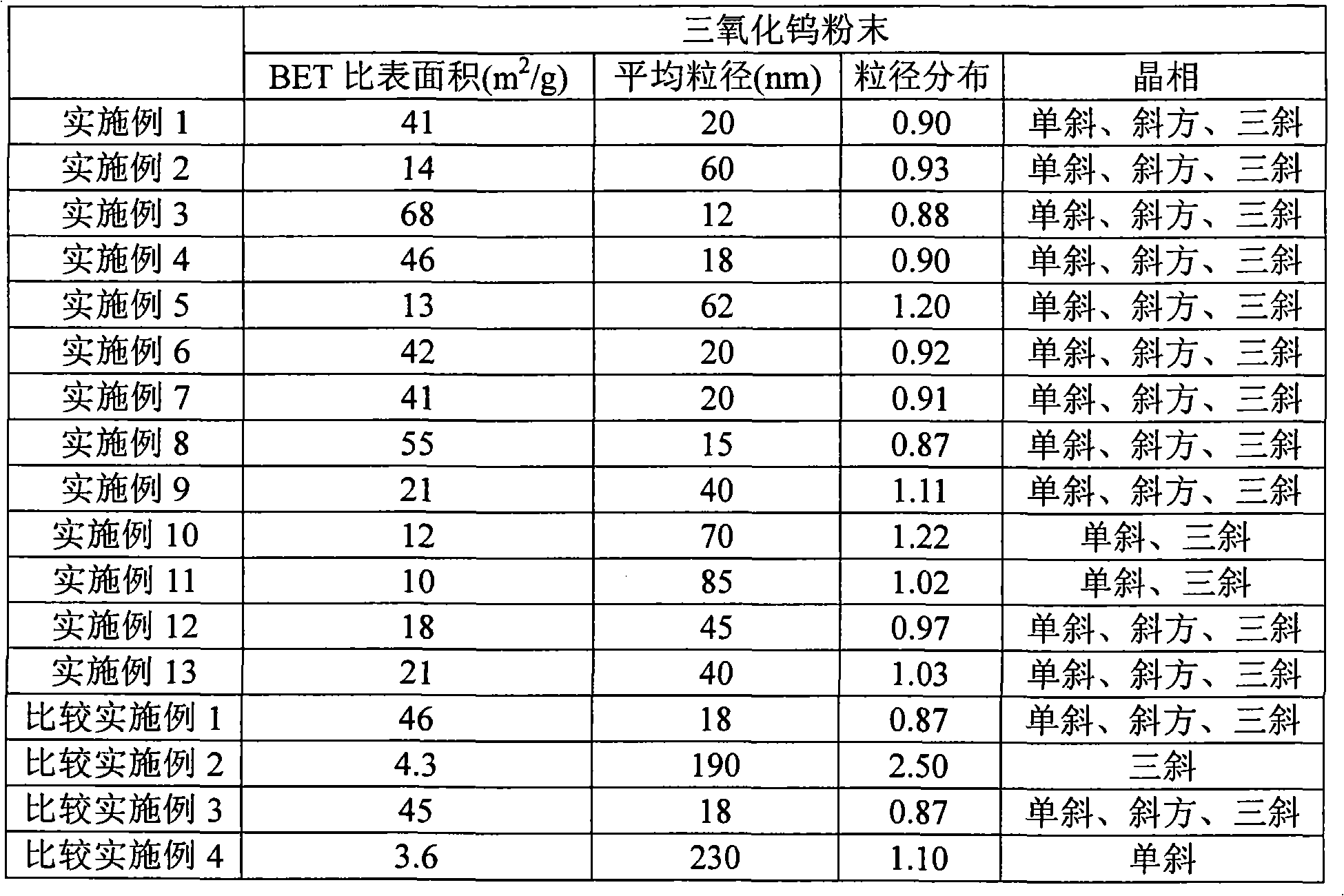

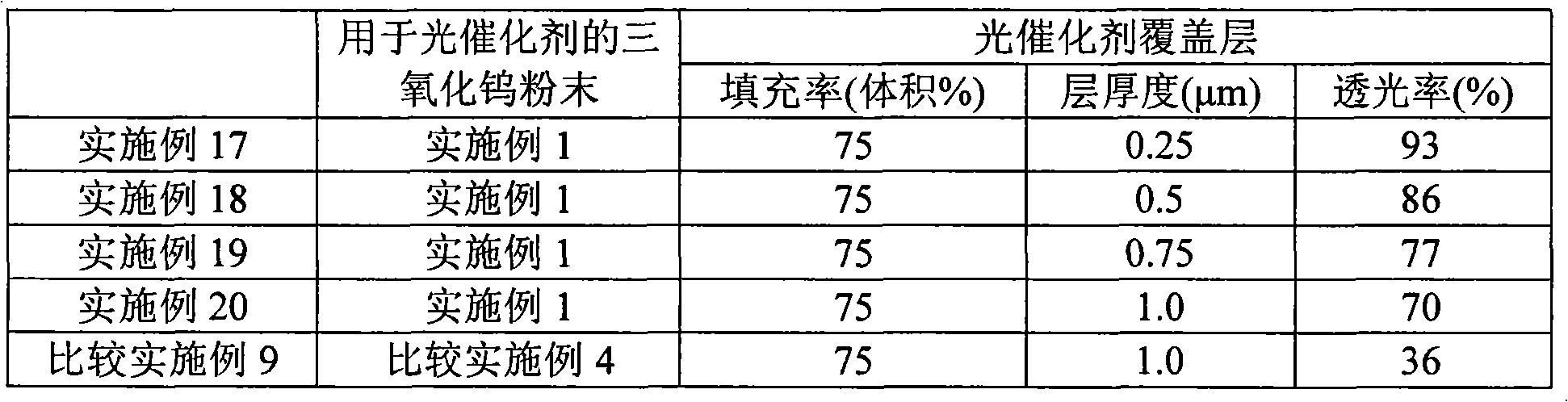

[0089] Tungsten trioxide powder having an average particle diameter of 0.5 μm was prepared as a raw material powder. In the sublimation step, while using the atmosphere (air) as a carrier gas, the raw material powder was sprayed into RF plasma and the average flow velocity was adjusted to 1 m / s, and the raw material powder was sublimated while undergoing an oxidation reaction. Tungsten trioxide powder is thus obtained by the sublimation step.

[0090] Then, the obtained tungsten trioxide powder was subjected to a heat treatment step of 530° C.×1 hour in an air atmosphere. Thereby obtaining tungsten trioxide powder for photocatalyst.

[0091] For the obtained tungsten trioxide powder for photocatalyst, the BET specific surface area, particle size distribution and crystal phase were measured. As for the particle size distribution parameter, a (D90-D10) / D50 value calculated from D90, D50, and D10 obtained by calculating the cumulative diameter of 150 or more crystal grains obta...

Embodiment 2

[0094] Tungsten metal powder having an average particle diameter of 1 μm was prepared as a raw material powder. In the sublimation step, while using the atmosphere (air) as a carrier gas, the raw material powder was sprayed into RF plasma and the average flow velocity was adjusted to 2 m / s, and the raw material powder was sublimated while undergoing an oxidation reaction. Tungsten trioxide powder is thus obtained by the sublimation step.

[0095] Then, the obtained tungsten trioxide powder was subjected to a heat treatment step of 600° C.×2 hours in an air atmosphere. Thereby obtaining tungsten trioxide powder for photocatalyst.

[0096] To the obtained tungsten trioxide powder for photocatalyst, carry out and embodiment 1 described identical measurement, and obtain following result: BET specific surface area is 14m 2 / g, the particle size distribution (D90-D10) / D50 is 0.93. Furthermore, it was found that the crystal phases consisted only of monoclinic crystals, orthorhombi...

Embodiment 3

[0098] Tungsten metal powder having an average particle diameter of 2 μm was prepared as a raw material powder. In the sublimation step, the raw material powder was mixed with water to prepare a dispersion liquid, which was sprayed into RF plasma while using the atmosphere (air) as a carrier gas, and the average flow velocity was adjusted to 0.5 m / s. The raw material powder is sublimated while undergoing an oxidation reaction, and tungsten trioxide powder is obtained through the sublimation step.

[0099] Then, the obtained tungsten trioxide powder was subjected to a heat treatment step at 550° C. for 30 minutes in an air atmosphere. Thereby obtaining tungsten trioxide powder for photocatalyst.

[0100] To the obtained tungsten trioxide powder for photocatalyst, carry out and embodiment 1 described identical measurement, and obtain following result: BET specific surface area is 68m 2 / g, the particle size distribution (D90-D10) / D50 is 0.88. Furthermore, it was found that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com