Oil gas recovery device and method of coating adsorption combination technology

A technology combining process and recovery method, which is applied in the field of oil and gas recovery devices in gas stations and oil depots, can solve the problems of difficult to reach the oil and gas concentration emission standards, and achieve the effect of remarkable separation effect, simple system structure and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

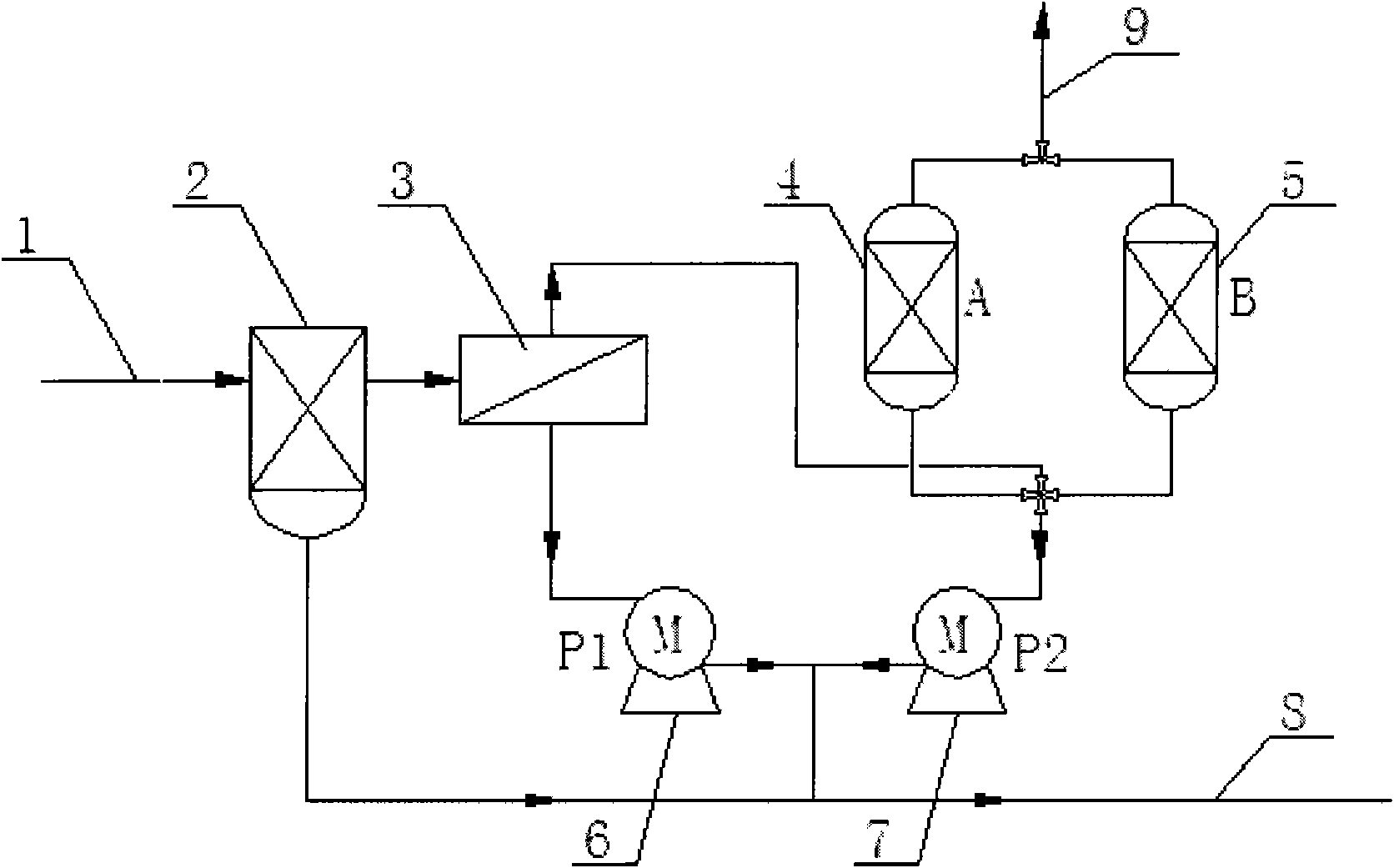

[0018] Such as figure 1 As shown, the specific process of the present invention is provided with a gas collector (1), an oil-gas separator (2), a membrane separator (3), an adsorber A (4), an adsorber B (5), and a vacuum pump P1 from left to right (6), vacuum pump P2 (7), oil return pipe (8) and discharge port (9) above the two adsorbers.

[0019] The connection of each part in the figure is as follows: the gas collecting pipe (1) is connected with the inlet end of the oil-gas separator (2); the outlet end of the top of the oil-gas separator (2) is connected with the inlet end of the membrane separator (3), and the oil-gas separation The outlet at the bottom of the device (2) is connected to the oil return pipe (8); the retentate gas outlet of the membrane separator (3) is connected to the inlet of the adsorber A (4) and the adsorber B (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com