Method for treating waste water from citric acid-production

A technology of citric acid wastewater and its treatment method, which is applied in natural water treatment, flotation water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of complex operation and poor treatment effect of citric acid wastewater, and achieve The effect of solving the shortage of water resources, good water quality and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

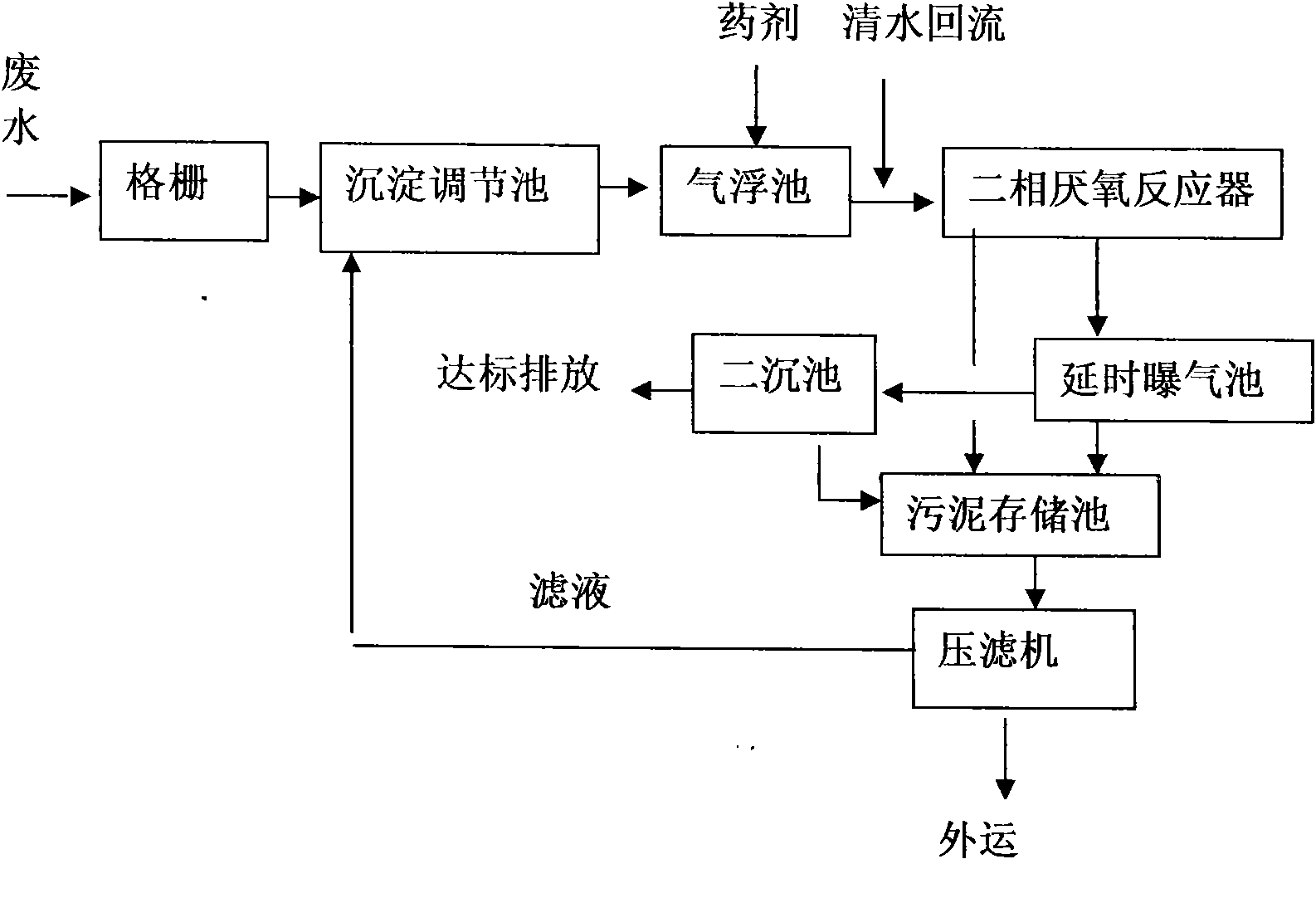

[0008] The present invention adopts two-phase anaerobic-aerobic combined process, and the processing capacity is 1000m 3 / d, specifically divided into three stages:

[0009] (1) Wastewater physical treatment stage. The waste water flows through the grid tank, sedimentation adjustment tank, and air flotation tank to effectively remove insoluble suspended solids and reduce the load of subsequent biochemical treatment. The sedimentation tank adopts the reinforced concrete advection type, one, underground type, which has the function of heat preservation, and because of the uneven production drainage, it also has the function of regulating tank, and the hydraulic retention time is 8h; the air flotation tank adopts the reinforced concrete advection type, one, the ground type, placed On the basis of the platform, the sewage can flow into the anaerobic pool by gravity.

[0010] (2) Wastewater biochemical treatment stage. The wastewater after physical treatment is diluted 1:1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com