Method for preparing hydrolyzed collagen protein by fresh animal skin

A technology for hydrolyzing collagen and animal skin, which is applied in the field of preparation of hydrolyzed collagen to achieve the effects of saving water resources, reducing energy consumption and production costs, and saving energy and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

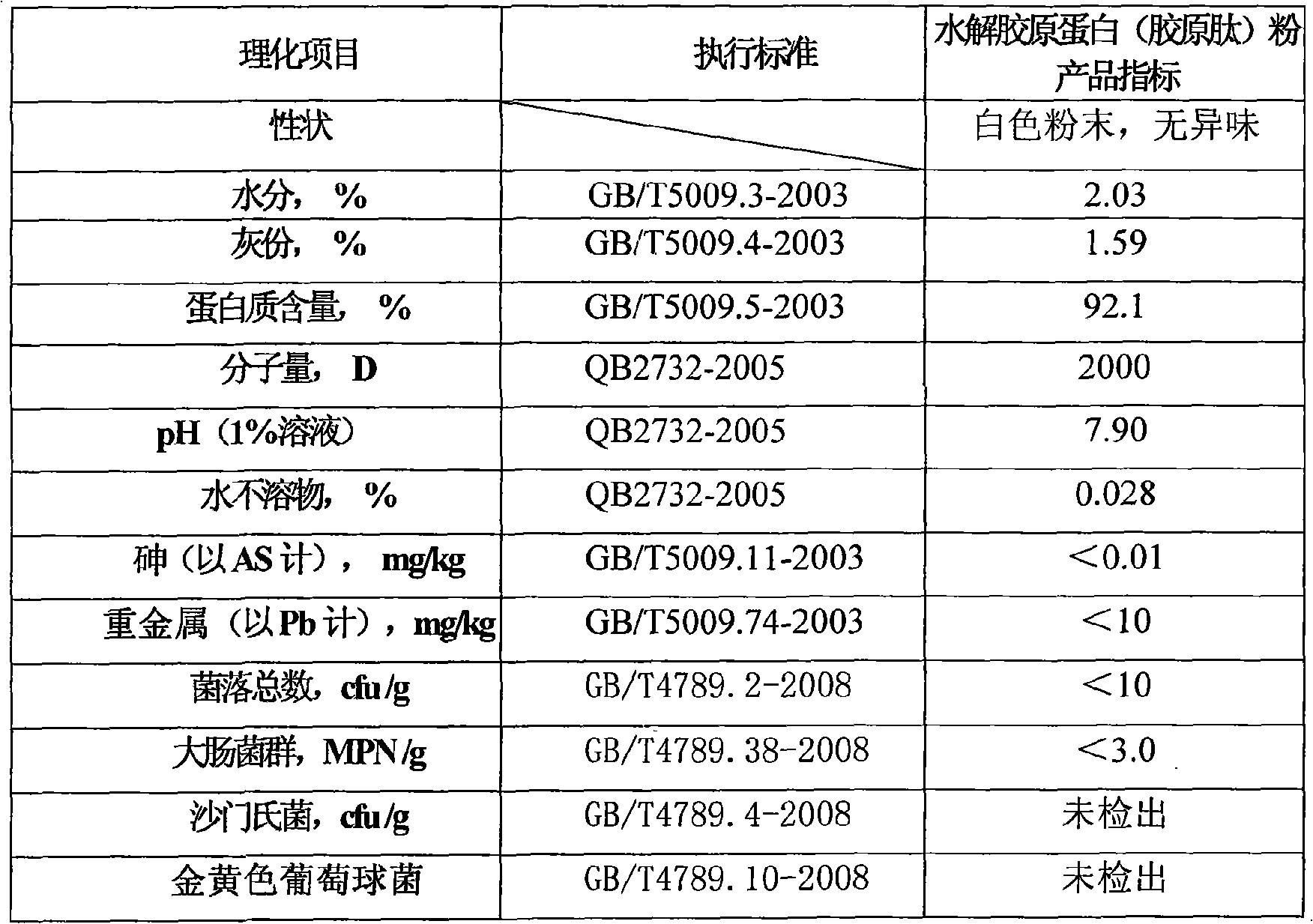

Embodiment 1

[0024] The process of preparing hydrolyzed collagen from pigskin is as follows:

[0025] (1) Preparatory work: After washing the container and pipeline, empty the container and pipeline with demineralized water.

[0026] (2) Mince fresh food-grade pigskin that has not been stored after depilation and degreasing, and requires length × width ≤ 1 × 1cm.

[0027] (3), enzymatic hydrolysis: add 1.5 tons of water and chopped pigskin with a wet weight of 110kg to the reactor, heat it to 60°C with steam under stirring, add 0.6Kg2709 protease, at this time the pH value is 8.0, heat preservation and stirring reaction 4 Hours, there is no blocky leather in the reactor at this time.

[0028] (4), removal of solid particles: the reaction solution of the (3) step reaction was left standstill for 0.7 hours, at this time the solid particles settled completely, and the solid particles and the grease layer were removed;

[0029] (5) Enzyme hydrolysis reaction-separation coupling: put the reac...

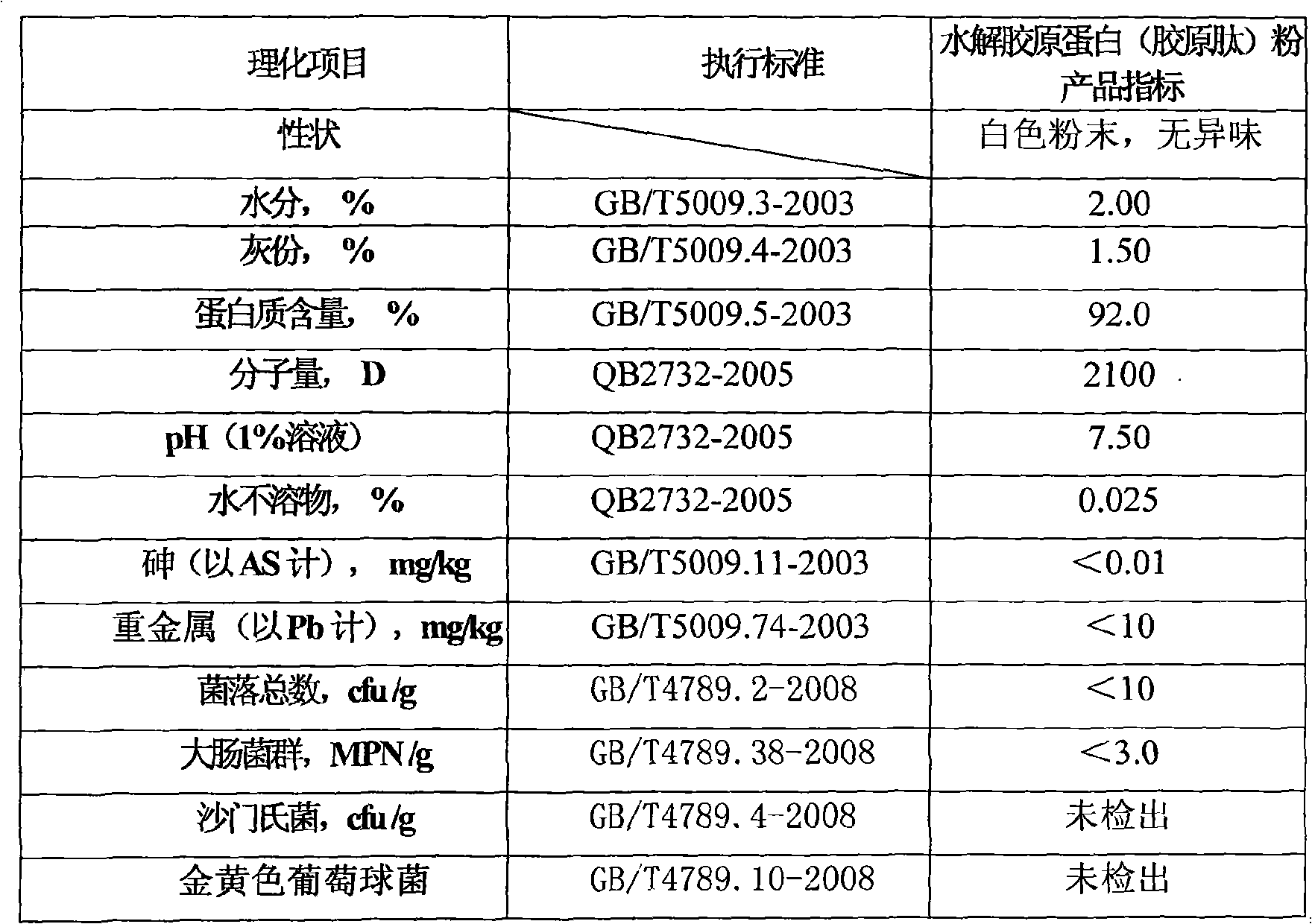

Embodiment 2

[0036] The process of preparing hydrolyzed collagen from sheepskin is as follows:

[0037] (1) Preparatory work: After washing the container and pipeline, empty the container and pipeline with demineralized water.

[0038] (2) Chopped fresh food-grade sheepskin that has been depilated and degreased without storage, requiring length × width ≤ 1 × 1cm;

[0039] (3) Enzymolysis: Add 1.5 tons of water and chopped sheepskin with a wet weight of 100kg to the reaction kettle, heat it to 40°C with steam under stirring, add 0.3Kg1398 protease, at this time the pH value is 8.2, and keep stirring for 5 hours , At this time, there is no lump leather in the reactor.

[0040] (4), removal of solid particles: the reaction solution of the (3) step reaction was left to stand for 0.5 hour, at this time the solid particles settled completely, and the solid particles and the grease layer were removed;

[0041] (5) Enzyme hydrolysis reaction-separation coupling: put the reaction solution after r...

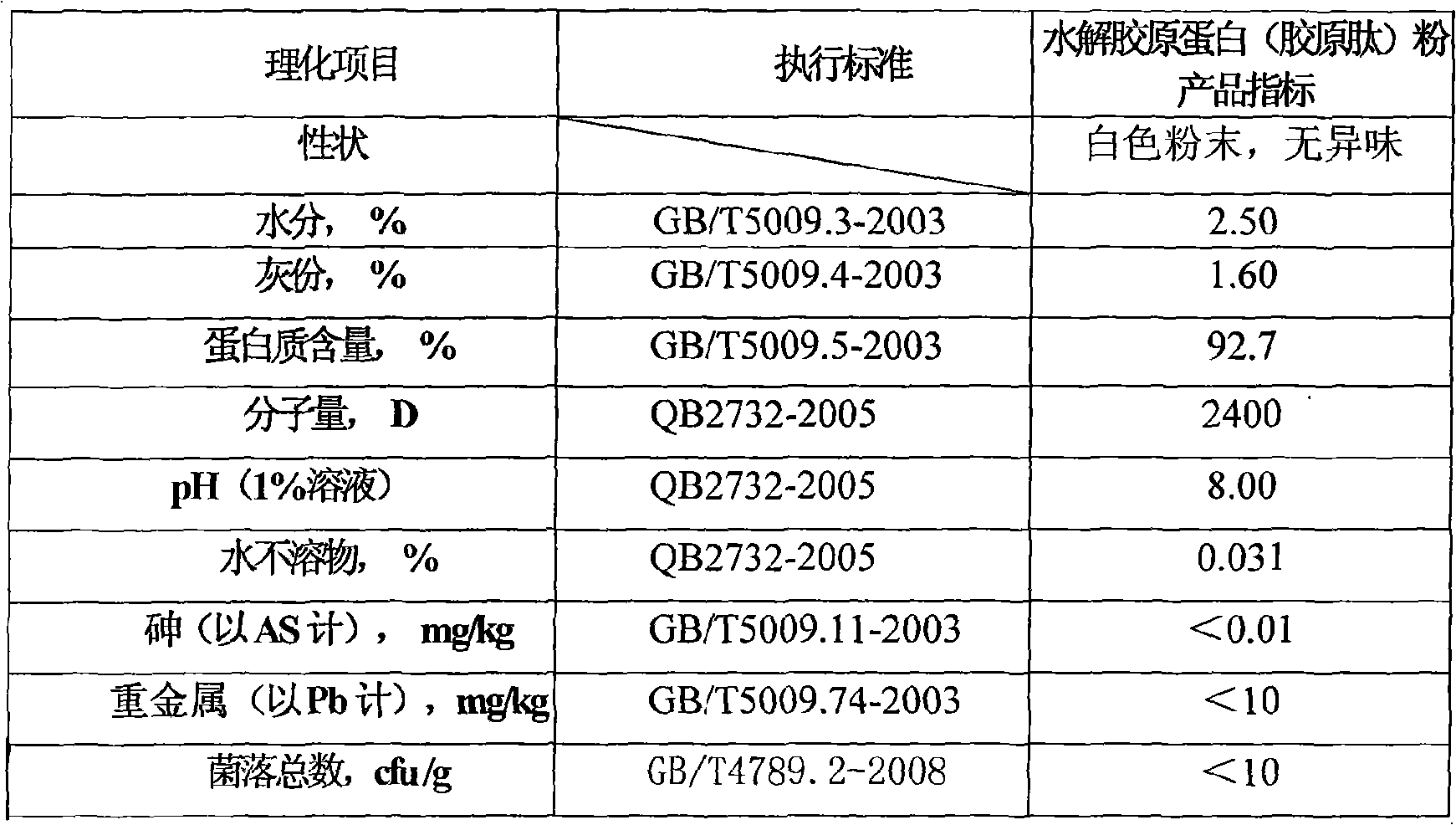

Embodiment 3

[0049] The process of preparing hydrolyzed collagen from cowhide is as follows:

[0050] (1) Preparatory work: After washing the container and pipeline, empty the container and pipeline with demineralized water.

[0051] (2) Mince unstored fresh food-grade cowhide after depilation and degreasing, requiring length × width ≤ 1 × 1cm;

[0052] (3) Enzymolysis: add 1.5 tons of water and 120kg of chopped cowhide to the reaction kettle, heat it with steam to 65°C under stirring, add 1.2Kg2709 protease, at this time the pH value is 8.5, and keep stirring for 3 hours , At this time, there is no lump leather in the reactor.

[0053] (4), removal of solid particles: the reaction solution of the (3) step reaction was left to stand for 1 hour, at this time the solid particles settled completely, and the solid particles and the grease layer were removed;

[0054] (5) Enzyme hydrolysis reaction-separation coupling: put the reaction solution after removing solid particles and grease layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com