Silver-copper nano alloy and preparation method thereof

A nano-alloy and alloy technology, applied in the field of silver-copper nano-alloy and its preparation, can solve the problems of inability to form an alloy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

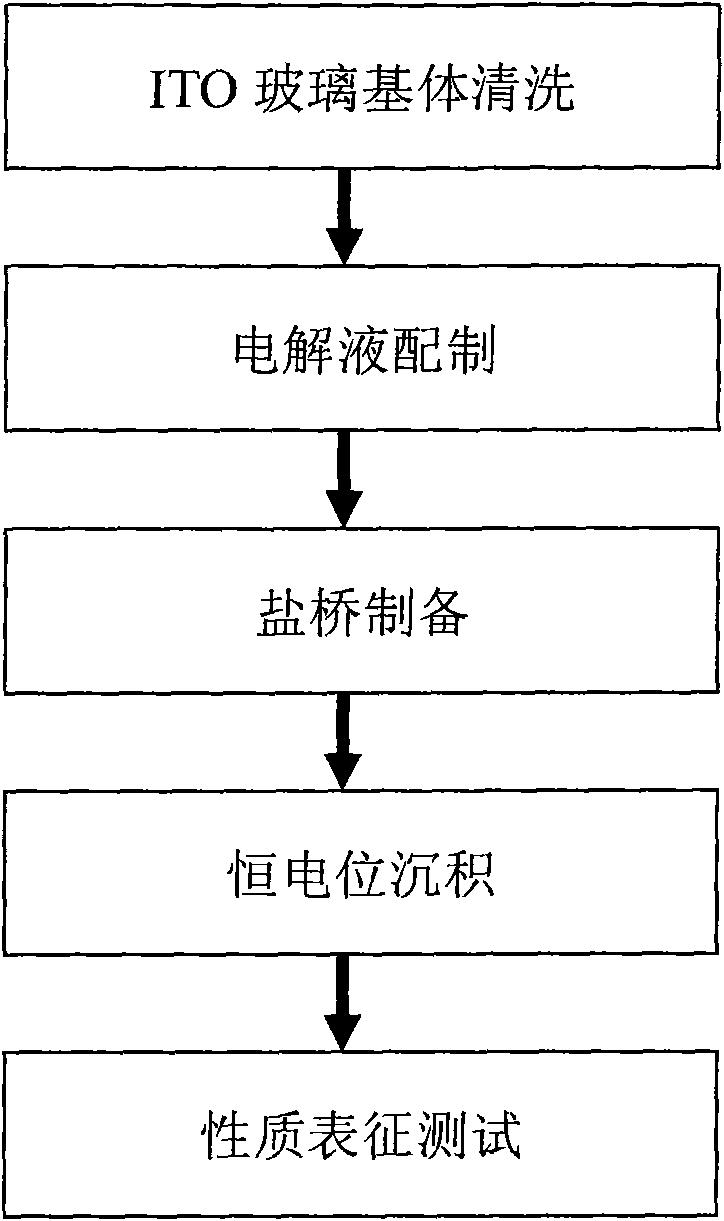

Method used

Image

Examples

Embodiment 1

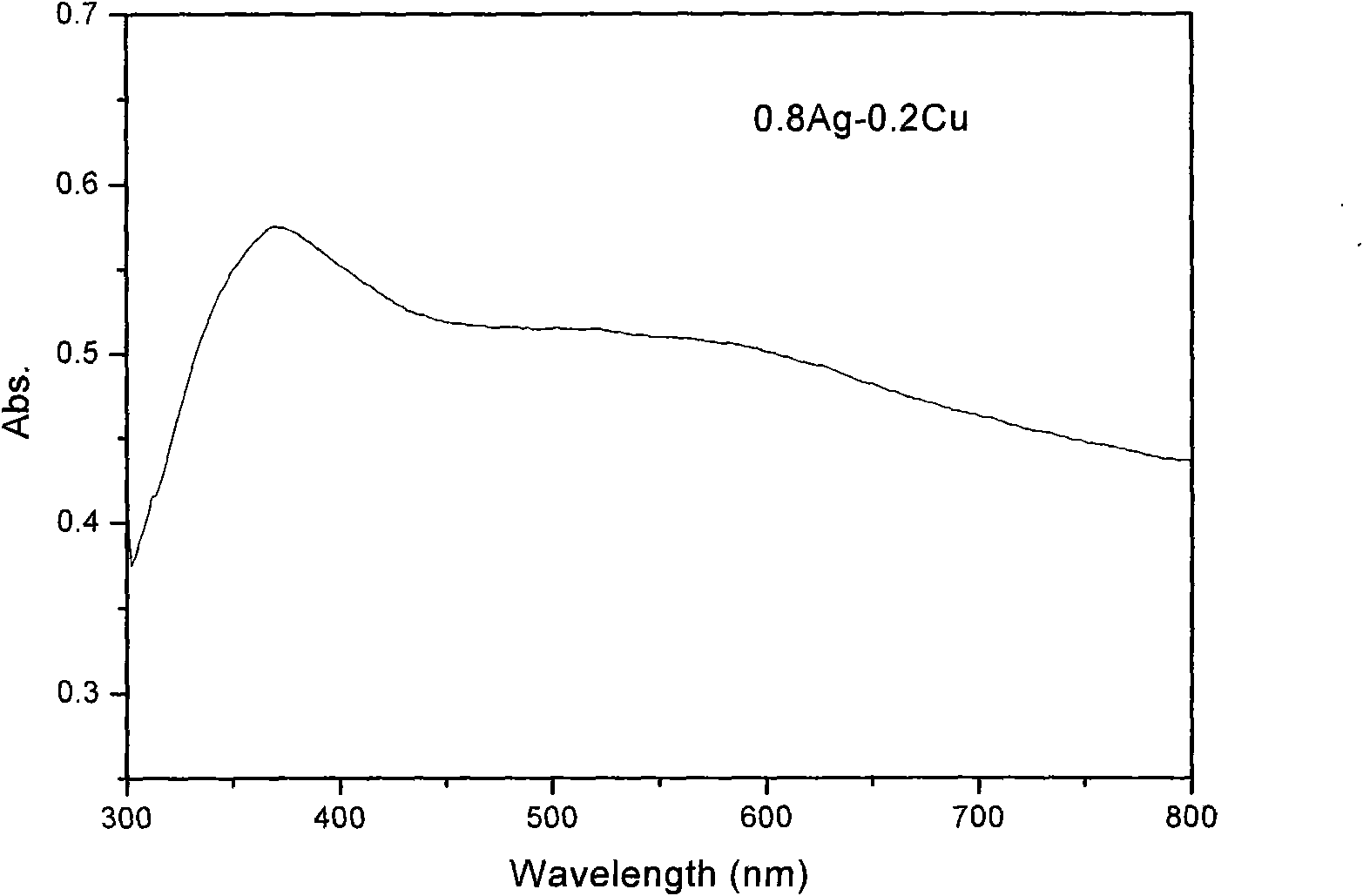

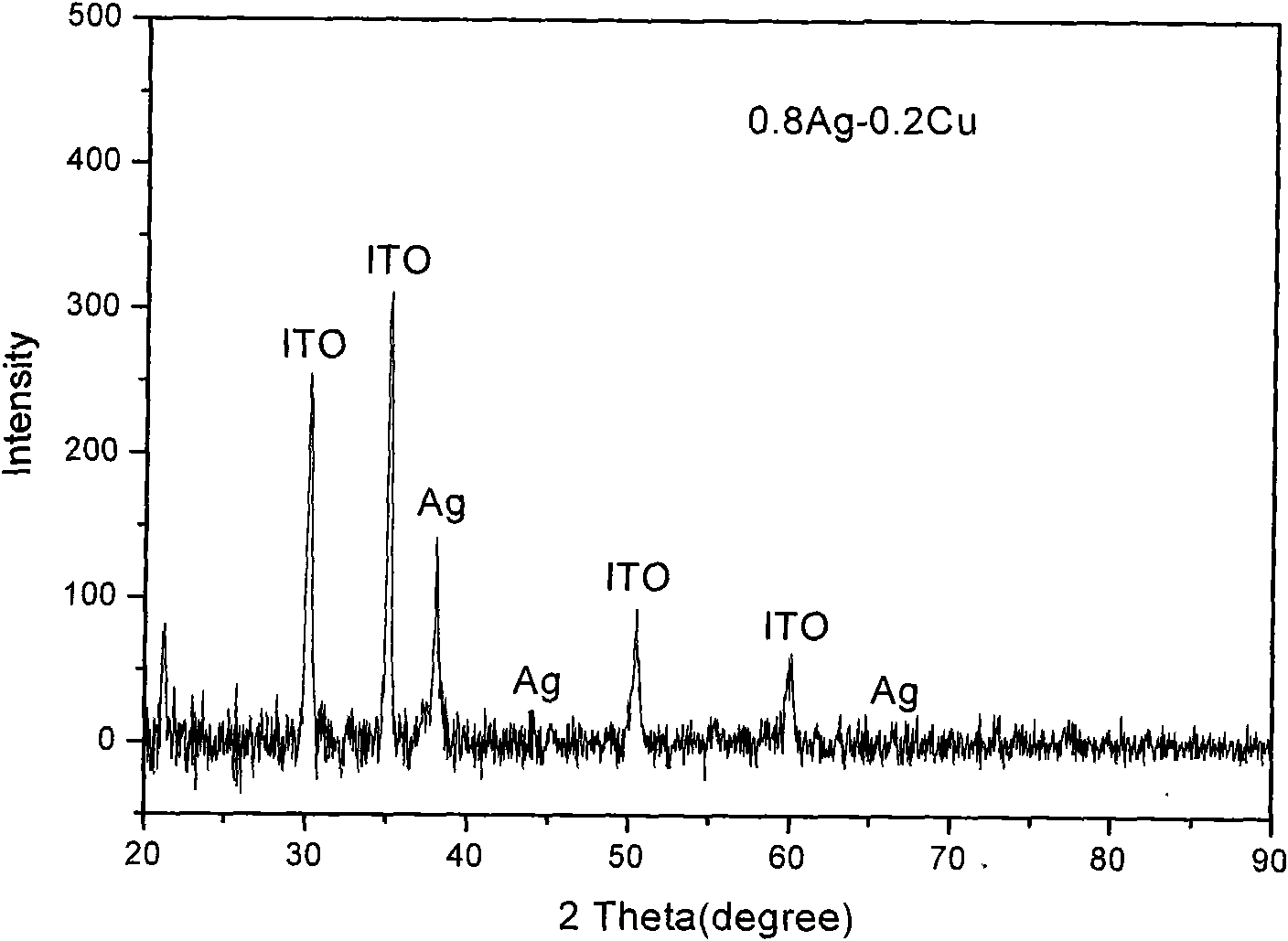

[0027] This embodiment is a silver-copper nano-alloy and its preparation method, wherein the molar composition of the silver-copper nano-alloy is (1-x)Ag-xCu, x=0.2 in this embodiment, the alloy composition is 0.8Ag-0.2Cu, The phase of the alloy is a single-phase solid solution with FCC structure; the microstructure of the alloy is dendrite, and the length of the primary dendrite of the selected alloy is 10-20 μm, the distance between the secondary dendrites is 100-200 nm, the length is 2-10 μm, and the third dendrite The crystal spacing is 10-20nm, and the length is 2-10nm. The preparation process of this embodiment comprises the following steps:

[0028] Step 1 Clean the ITO glass substrate

[0029] Soak the ITO glass substrate in 0.5mol / L NaOH solution for 15 minutes to increase the hydrophilicity of the ITO glass substrate; then rinse the ITO glass with deionized water; finally, ultrasonically clean the ITO in acetone solution for 15 minutes, to remove organic matter fro...

Embodiment 2

[0042] This embodiment is a silver-copper nano-alloy and its preparation method, wherein the molar composition of the silver-copper nano-alloy is (1-x)Ag-xCu, in this embodiment x=0.5, and the alloy composition is 0.5Ag-0.5Cu; The phase of the alloy is a single-phase solid solution with FCC structure; the microstructure of the alloy is dendrite, and the length of the primary dendrite of the selected alloy is 10-20 μm, the distance between the secondary dendrites is 100-200 nm, the length is 2-10 μm, and the third dendrite The crystal spacing is 10-20nm, and the length is 2-10nm. In this example, three samples were prepared under different deposition voltages, and the specific preparation process is as follows:

[0043] Step 1 Clean the ITO glass substrate

[0044] Soak the ITO glass substrate in 0.5mol / L NaOH solution for 15 minutes to increase the hydrophilicity of the ITO glass substrate; then rinse the ITO glass with deionized water; finally, ultrasonically clean the ITO i...

Embodiment 3

[0057] This embodiment is a silver-copper nano-alloy and its preparation method, wherein the molar composition of the silver-copper nano-alloy is (1-x)Ag-xCu, x=0.8 in this embodiment, and the alloy composition is 0.2Ag-0.8Cu; The phase of the alloy is a single-phase solid solution with FCC structure; the microstructure of the alloy is dendrite, and the length of the primary dendrite of the selected alloy is 10-20 μm, the distance between the secondary dendrites is 100-200 nm, the length is 2-10 μm, and the third dendrite The crystal spacing is 10-20nm, and the length is 2-10nm. In this example, three samples were prepared under different deposition voltages, and the specific preparation process is as follows:

[0058] Step 1 Clean the ITO glass substrate

[0059] Soak the ITO glass substrate in 0.5mol / L NaOH solution for 15 minutes to increase the hydrophilicity of the ITO glass substrate; then rinse the ITO glass with deionized water; finally, ultrasonically clean the ITO i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com