Sheathing paper containing bamboo charcoal particles

A heat-insulating paper and particle technology, applied in paper, papermaking, special paper, etc., can solve the problems of difficult production, complicated processing, poor heat insulation effect, etc., and achieve the effect of easy grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above and other features and advantages of the present invention will be described in detail below with reference to the accompanying drawings.

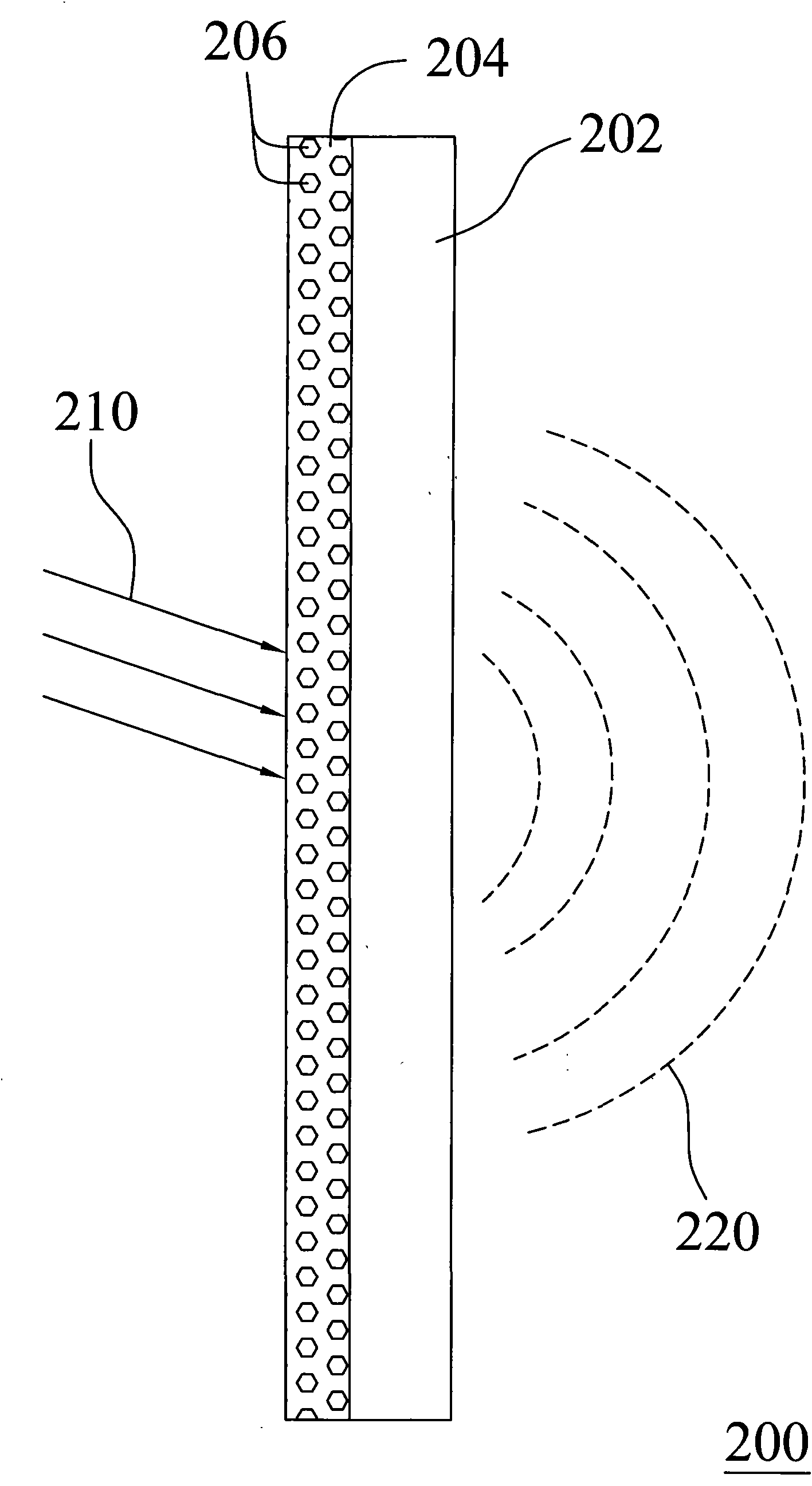

[0020] see figure 2 , figure 2 Shown is the heat insulation mechanism of the first embodiment of the heat insulation paper disclosed by the present invention. Wherein, the thermal insulation paper 200 includes a base material 202 and a thermal insulation layer 204 . In addition, the thermal insulation layer 204 contains nano bamboo charcoal particles 206 . When an incident light 210 is given to the insulation paper 200 , the bamboo charcoal particles 206 will absorb part of the near-infrared light and convert it into far-infrared light 220 to release.

[0021] The remainder of the insulating layer 204 is adhesive, which is suitably cross-linked by (meth)acrylic polymers. The method of cross-linking is to use a cross-linking agent, which can be isocyanate compound, epoxy compound, melamine resin, and the cross-linking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com