Dry-type film oxygen enriching device

A dry-type membrane and oxygen-enriched technology, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of complex supporting structure, difficult operation and maintenance, high production cost, etc., and achieve high oxygen concentration and good combustion-supporting effect , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

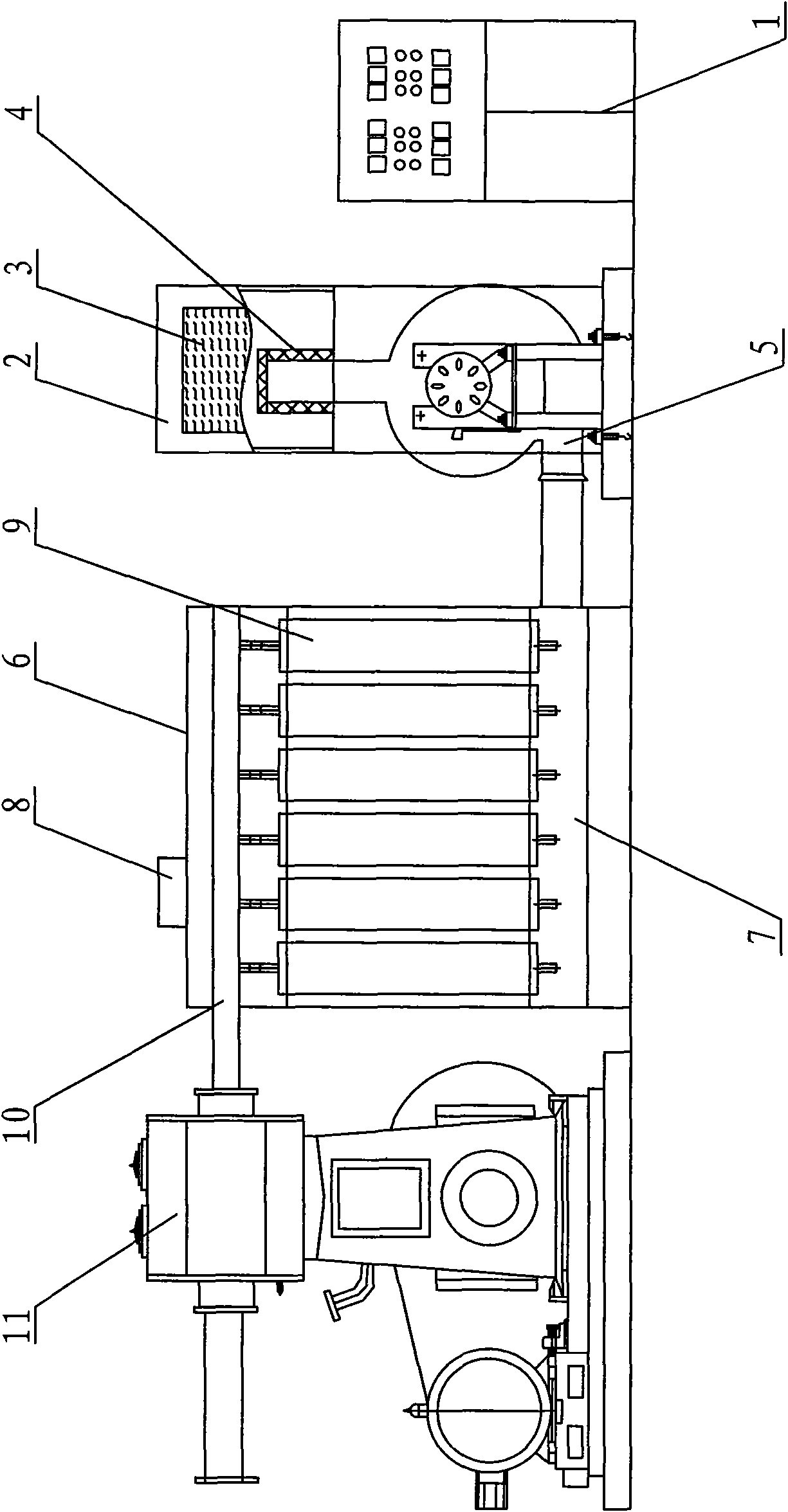

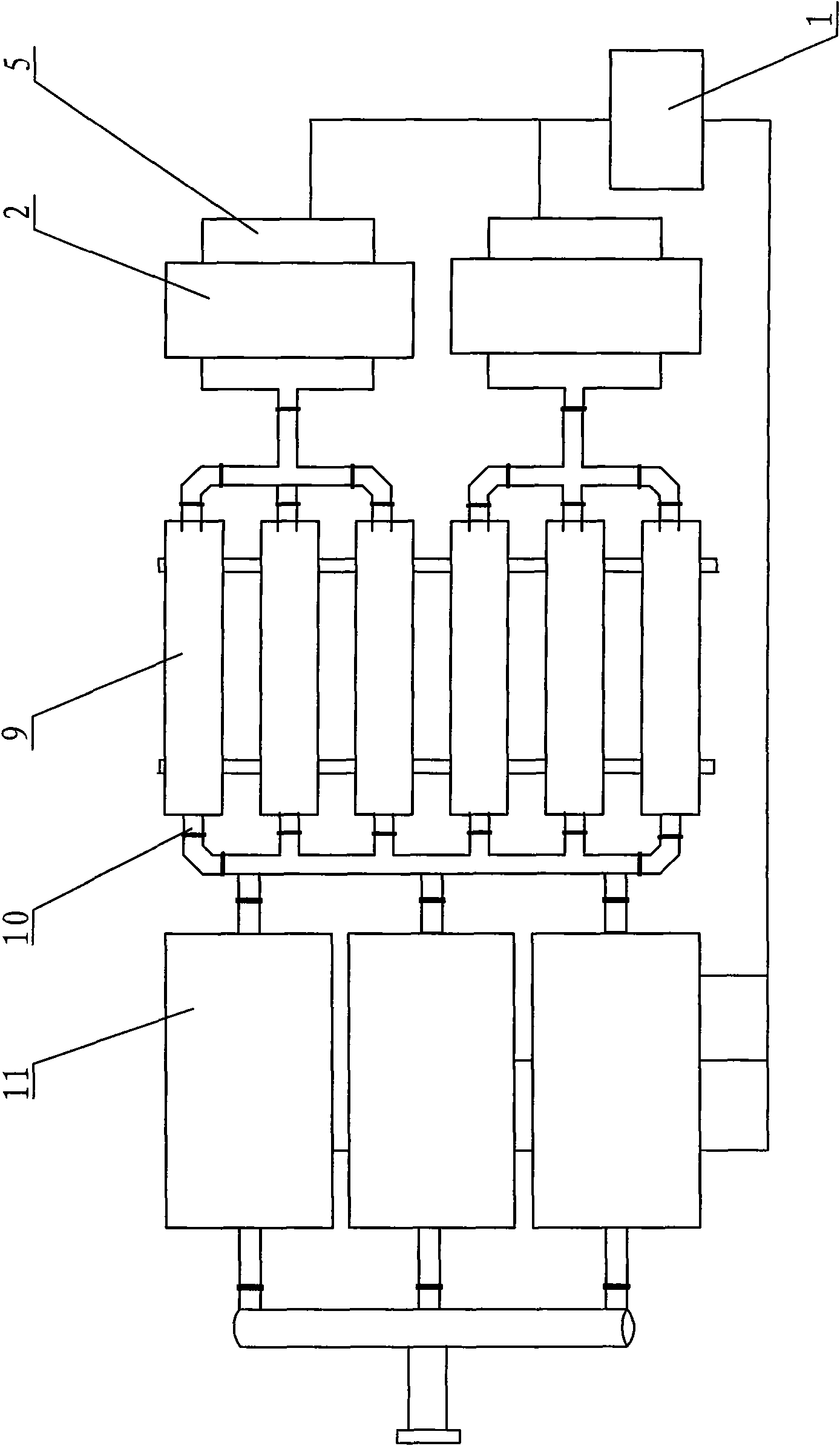

[0019] figure 1 The dry-type membrane oxygen enrichment device shown is mainly composed of a control system 1, an air filter device 2, a high-pressure centrifugal fan 5, an oxygen enrichment tank 6, and an oil-free vacuum pump 11 skid-mounted in one body. The shell of the air filter device 2 is provided with a filter screen 3, and the inside of the air filter device is provided with a filter element 4 placed at the air inlet of the high-pressure centrifugal fan 5; The top of the oxygen-enriched box 6 is provided with a waste gas discharge port 8, and the bottom of the oxygen-enriched box 6 is provided with an air box 7 connected to the air outlet of the high-pressure centrifugal fan 5. The oxygen-enriched membrane module is composed of a plurality of oxygen-enriched membranes 9 arranged side by side on the air box 7 , the air inlet of each oxygen-enriched membrane 9 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com