Method for preparing industrial calcium chloride

A technology for the production of industrial calcium chloride, applied in chemical instruments and methods, calcium/strontium/barium chloride, inorganic chemistry, etc., can solve the problems of reducing the economic value of aquatic products, polluting the environment, etc., to avoid ecological environment pollution, Less secondary pollution, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

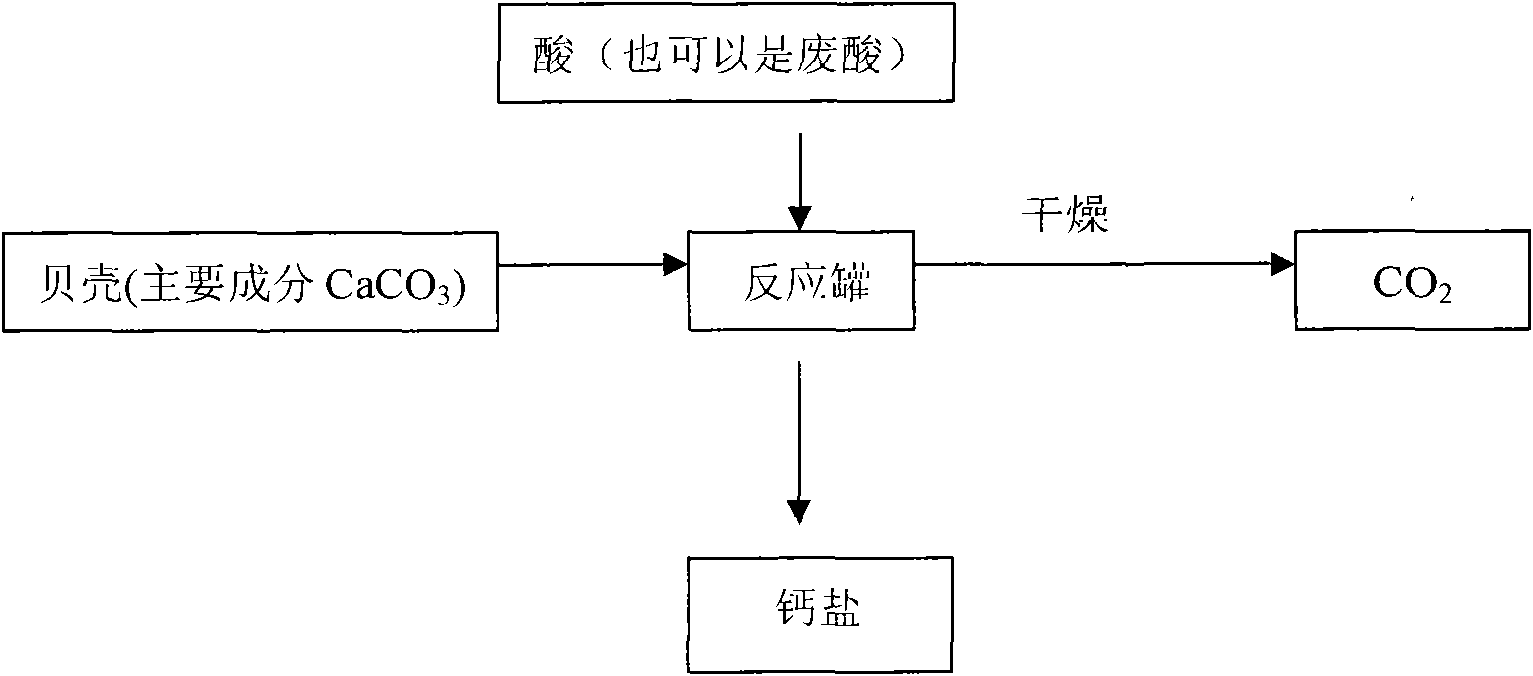

Method used

Image

Examples

Embodiment 1

[0018] The first step: shell pretreatment: remove the soil and other sundries on the surface of the shell with clean water, then crush it, store the powdered shell powder separately for later use, and control the particle size of the shell after crushing to about 16-20 mesh, because the particle size is too large It is inconvenient to stir during the reaction, and the particle size is too small and will be ejected by air bubbles during the reaction.

[0019] The second step: reaction stage: get 1.06 parts of pulverization (containing 1 part of calcium carbonate) and join in the middle of the reactor, under stirring condition, add concentrated hydrochloric acid (mass concentration 36%) slowly to the reaction that has been equipped with pulverized shell particles In the tank, control the acid addition rate at 1-1.5L / h, so as to avoid the phenomenon of "boiling" in the reaction tank when the acid addition rate is too fast. If the phenomenon of "potting" occurs, it can be solved b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com