Method for removing chlorine in chlorinated organic pollutant through electrochemistry method

A pollutant and electrochemical technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of less microbial species, reduced biodegradability, poor degradation effect, etc., and achieve dechlorination efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

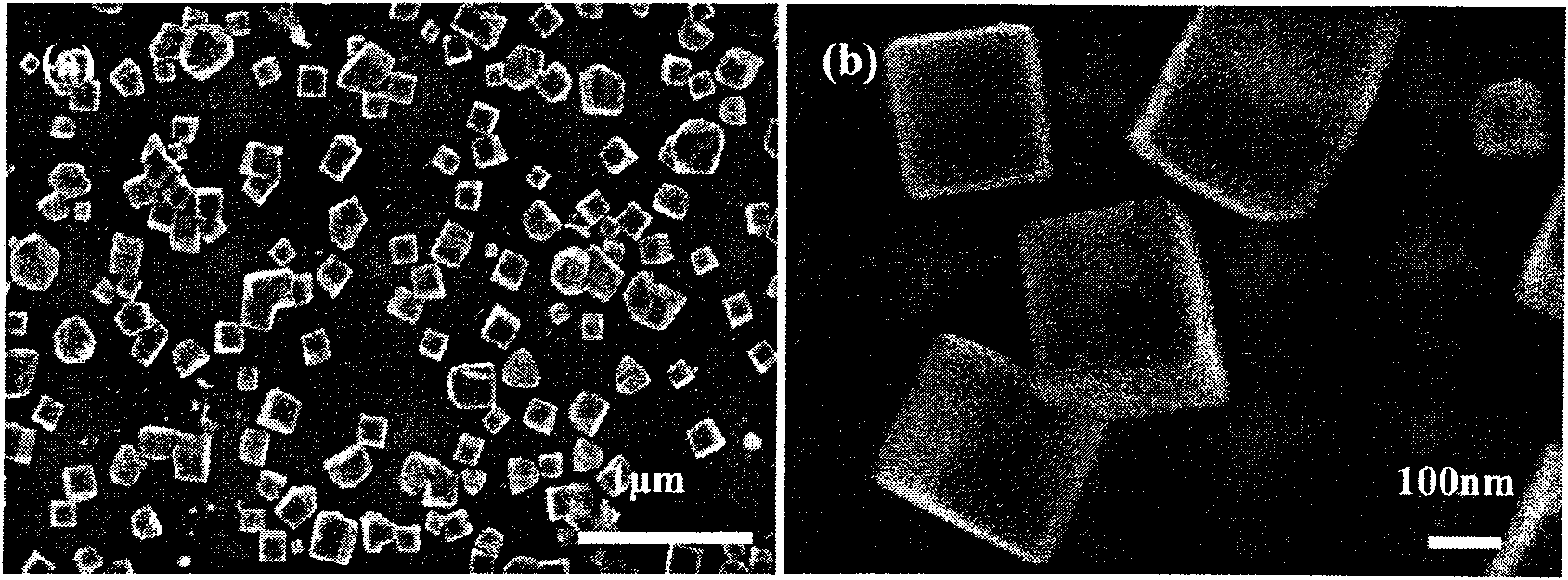

[0024] Preparation of glassy carbon electrode modified with core-shell nano bimetallic Fe / Pd catalyst:

[0025] First polish the glassy carbon electrode with 3500# metallographic sandpaper, and then polish the mirror surface of the paper with 0.5μm alumina powder. Before the experiment started, the glassy carbon electrode was first placed in HNO 3 Solution (HNO 3 :H 2 (O volume ratio 1:1) ultrasonic 5min, and then rinse with ultrapure water. The electrochemical experiments were all carried out in the electrolytic cell of the traditional three-electrode system: a clean glassy carbon electrode was used as the working electrode, a Pt sheet was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode.

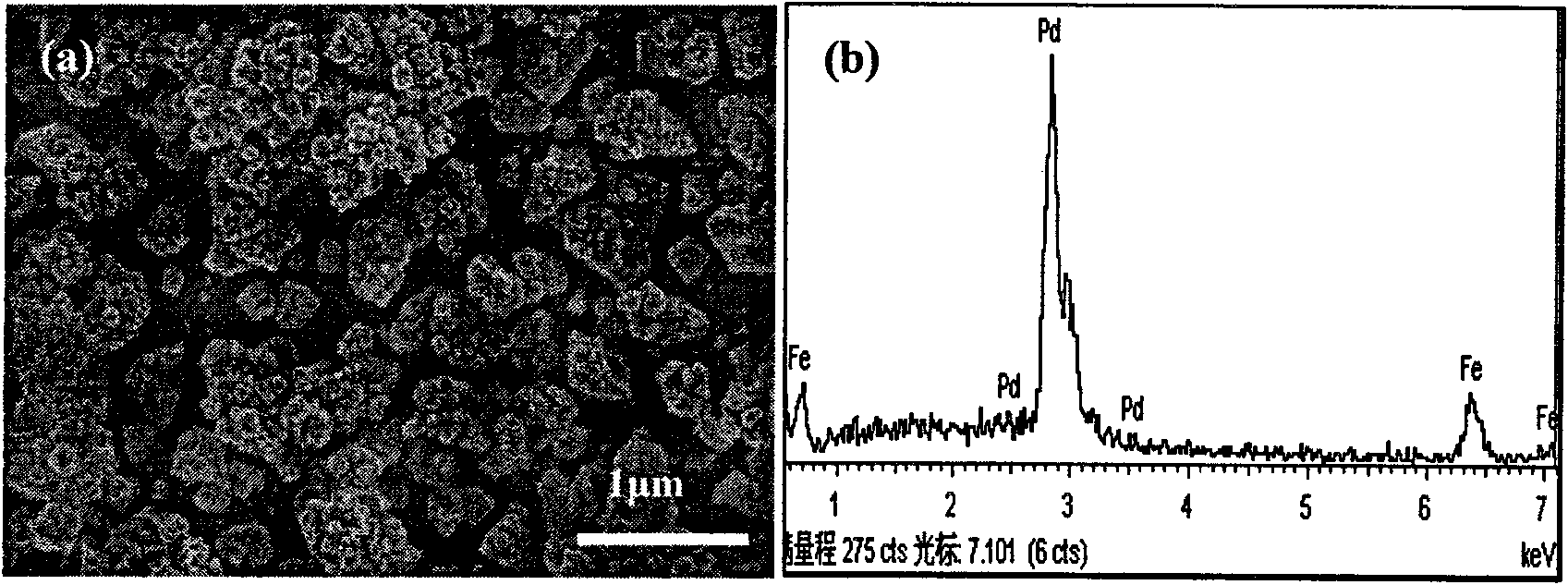

[0026] NaCl and FeCl 2 The mixed solution of NaCl is used as the deposition solution, and the concentration of NaCl is 0.25mol dm -3 , FeCl 2 The concentration is 10mmol dm -3 , control the temperature at 30°C, and deposit a large ...

Embodiment 2

[0029] Method for electrochemical dechlorination of organic chlorinated pollutants:

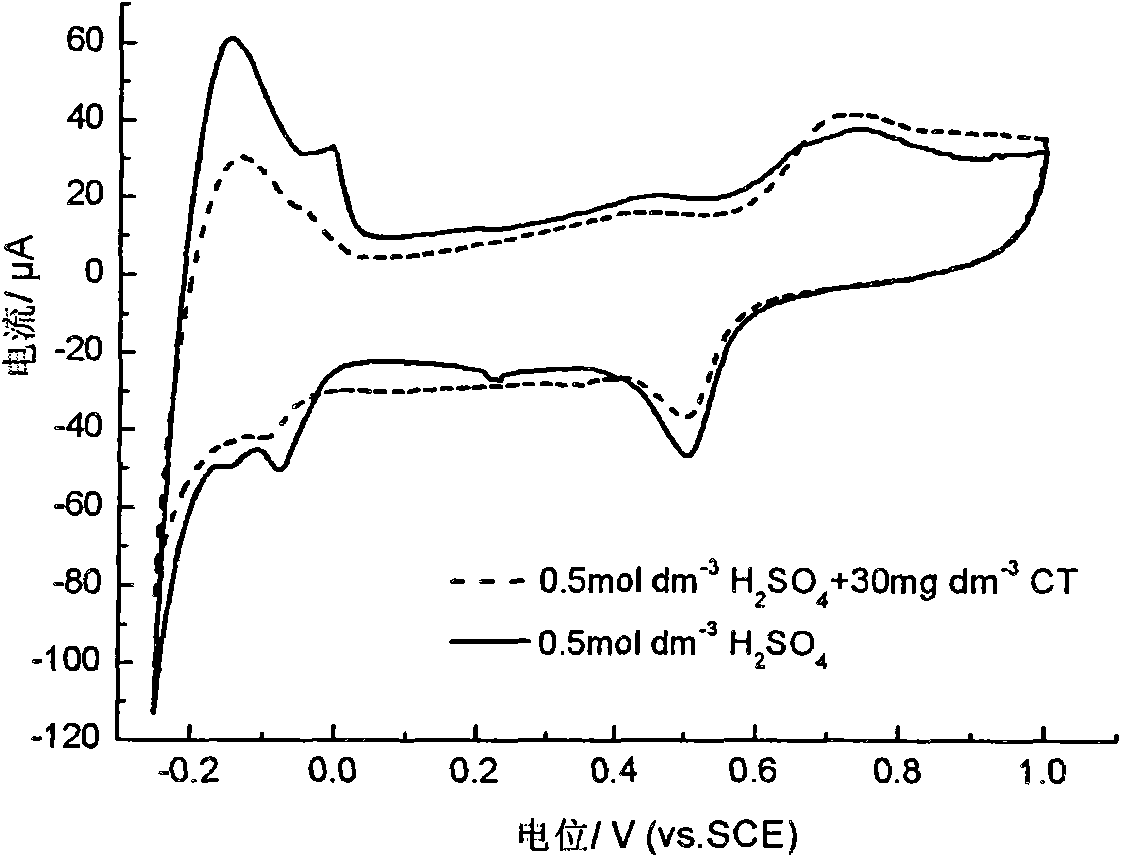

[0030] The glassy carbon electrode modified with the core-shell nano-bimetallic Fe / Pd catalyst prepared in Example 1 is used as the working electrode, the Pt sheet is used as the counter electrode, and the saturated calomel electrode is used as the three-electrode system of the reference electrode, respectively at 0.5 mol dm -3 h 2 SO 4 solution, H 2 SO 4 solution with CCl 4 Mixed solution (0.5mol dm -3 h 2 SO 4 , 30 mg dm -3 CCl 4 ) for cyclic voltammetry scanning, the scanning potential range is -0.2V~+1.0V, and the scanning speed is 50mV s -1 , the number of cycles is 3 cycles, and the range of the hydrogen zone is determined to be -0.2V to 0.05V; according to the determined range of the hydrogen zone, at 0.5mol dm -3 h 2 SO 4 solution, H 2 SO 4 solution with CCl 4 Mixed solution (0.5mol dm -3 h 2 SO 4 , 30 mg dm -3 CCl 4 ), respectively at -0.05V, -0.08V, -0.1V, -0.15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com