Powder mortar composite for bubble lightweight concrete

A technology of lightweight concrete and dry powder mortar, which is applied in the field of special dry powder mortar composition for bubble lightweight concrete, and achieves the effects of stable strength, stable mechanical properties and excellent hydrophobicity in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

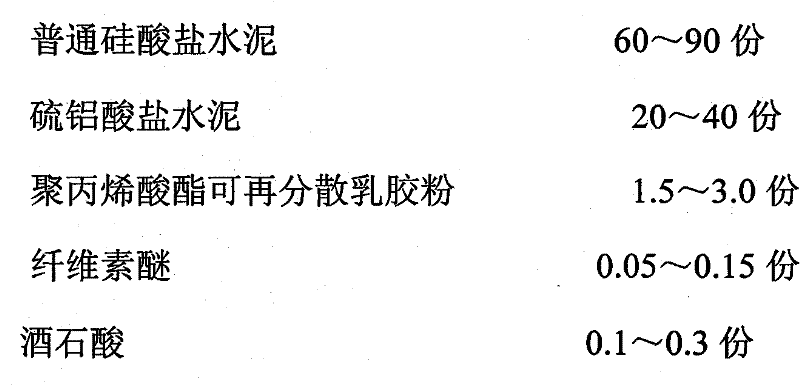

Method used

Image

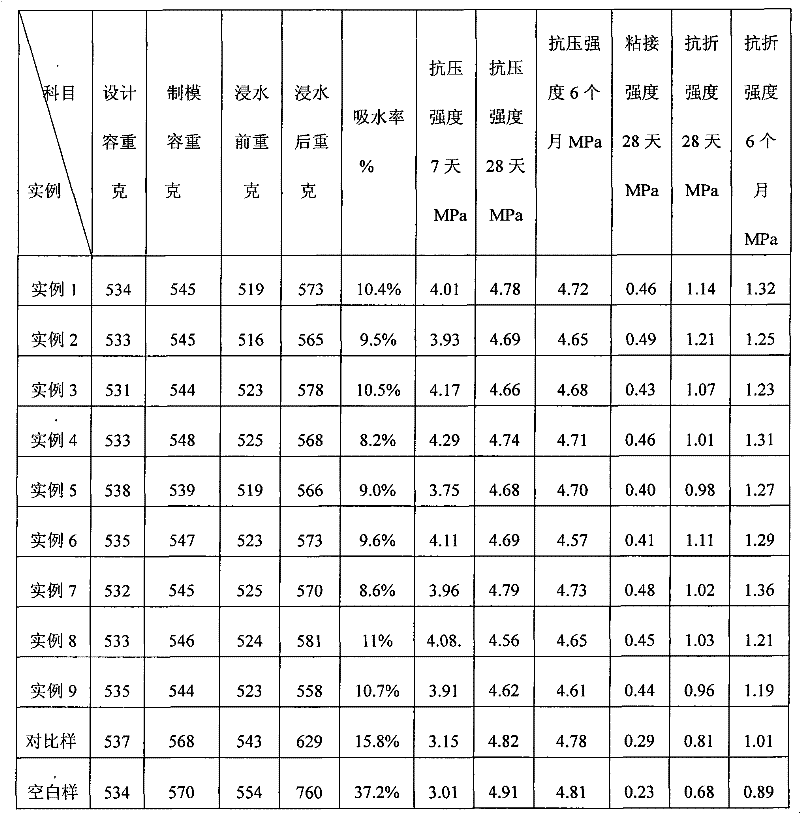

Examples

Embodiment 1

[0020] Ordinary Portland cement (Shanghai Xiang brand (42.5)) 6000 grams, sulfoaluminate cement (Tangshan Liujiu brand (42.5) rapid hardening sulfoaluminate cement) 4000 grams, polyacrylate redispersible latex powder (Shanghai Dongsheng VAP-360) 150 grams, hydroxyethyl cellulose ether (20,000 molecular weight, the brand name of Rongou Chemical Shanghai Co., Ltd. is MK-20000S cellulose ether) 5 grams, tartaric acid 30 grams;

[0021] Preparation method: at 70°C, add ordinary portland cement into a stirring pot, while stirring, add sulphoaluminate cement, polyacrylate redispersible latex powder, hydroxyethyl cellulose ether, tartaric acid in sequence, and stir for 30 Minutes, made into dry powder, then bagged and packaged, and water was added during use, and the added weight of water was 5600 grams.

Embodiment 2

[0023] Ordinary Portland cement (Shanghai Xiang brand (42.5)) 7000 grams, sulfoaluminate cement (Tangshan Liujiu brand (42.5) rapid hardening sulfoaluminate cement) 3000 grams, polyacrylate redispersible latex powder (Shanghai Dongsheng VAP-360) 200 grams, hydroxyethyl cellulose ether (20,000 molecular weight Rongou Chemical Shanghai Co., Ltd. brand is MK-20000S cellulose ether) 7.5 grams, tartaric acid 20 grams, water 5600 grams.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Ordinary Portland cement (Shanghai Xiang brand (42.5)) 8000 grams, sulfoaluminate cement (Tangshan Liujiu brand (42.5) rapid hardening sulfoaluminate cement) 2000 grams, polyacrylate redispersible latex powder (Shanghai Dongsheng VAP-360) 300 grams, hydroxyethyl cellulose ether (20,000 molecular weight Rongou Chemical Shanghai Co., Ltd. brand is MK-20000S cellulose ether) 10 grams, tartaric acid 10 grams, water 5600 grams. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com