Method for preparing polyvinylidene fluoride polarizable film

A technology of polyvinylidene fluoride and film, which is applied in the field of preparation of polarized polyvinylidene fluoride film, can solve problems such as unsuitable for industrial production, polyvinylidene fluoride copolymer is not good, etc., and achieve film thickness controllability and film forming Convenient and reasonable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a polyvinylidene fluoride polarizable film, the method comprising the following steps:

[0025] (1) Montmorillonite (cation exchange capacity 85mequiv·100g -1 ) was dispersed in deionized water, stirred at 70°C for 4 hours to obtain a montmorillonite suspension with a concentration equal to 2wt%, and set aside;

[0026] (2) dissolving polyvinylidene fluoride (PVDF) in N,N-dimethylformamide to make a solution with a concentration equal to 5wt% polyvinylidene fluoride;

[0027] (3) Mix the above polyvinylidene fluoride solution and montmorillonite suspension according to the mass ratio (100:0; 97.5:2.5; 95:5; 88.4:11.6; 78:22; 61.5:38.5) Polyvinylidene fluoride polarizable film was prepared by pouring and volatile solvent at 120°C. The content of montmorillonite in the film was 0wt%, 1wt%, 2wt%, 5wt%, 10wt% and 20wt%, and the thickness of the film was 0.01mm .

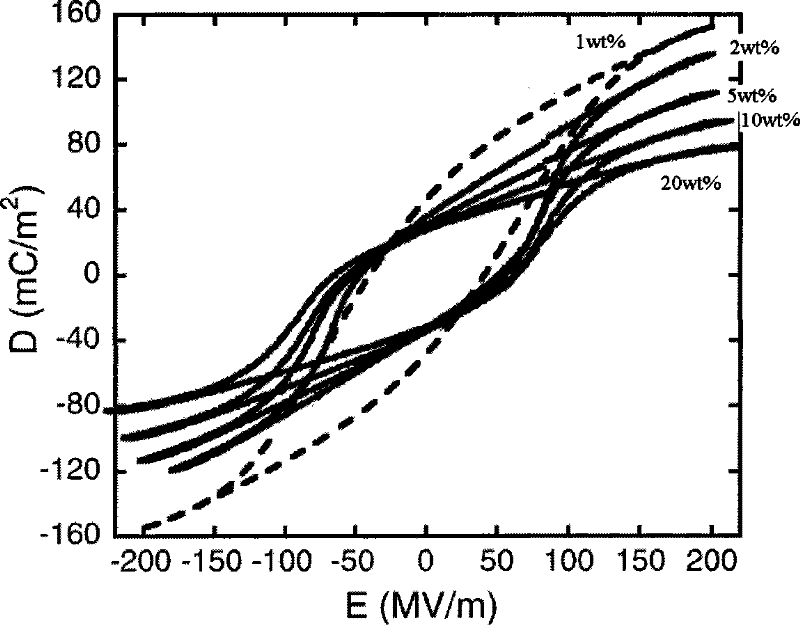

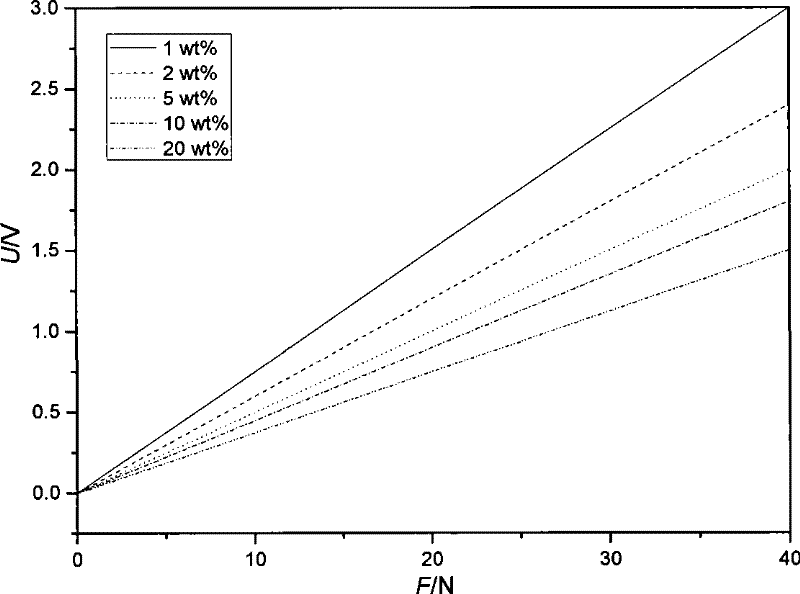

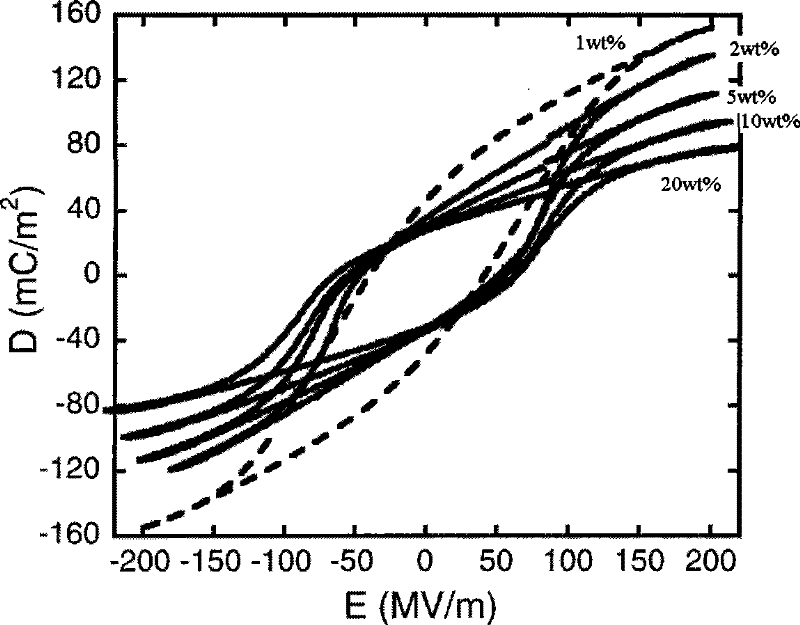

[0028] Cut the 0.01mm thick film obtained above into 1×1cm 2 Size, its voltage capac...

Embodiment 2

[0030] A method for preparing a polyvinylidene fluoride polarizable film, the method comprising the following steps:

[0031] (1) The original soil of montmorillonite (cation exchange capacity 100mequiv·100g -1 ) was dispersed in deionized water, stirred at 70°C for 4 hours to obtain a montmorillonite suspension with a concentration equal to 4wt%, and set aside;

[0032] (2) dissolving industrial grade polyvinylidene fluoride (PVDF) in industrial grade N,N-dimethylacetamide to make a solution with a concentration equal to 10wt% polyvinylidene fluoride;

[0033] (3) Mix the above polyvinylidene fluoride solution and montmorillonite suspension according to the mass ratio (100:0; 97.5:2.5; 95:5; 88.4:11.6; 78:22; 61.5:38.5) Polyvinylidene fluoride polarizable film was prepared by pouring and volatile solvent at 120°C. The content of montmorillonite in the film was 0wt%, 1wt%, 2wt%, 5wt%, 10wt% and 20wt%, and the thickness of the film was 0.01mm .

Embodiment 3

[0035] A method for preparing a polyvinylidene fluoride polarizable film, the method comprising the following steps:

[0036] (1) The original soil of montmorillonite (cation exchange capacity 120mequiv·100g -1 ) was dispersed in deionized water, stirred at 50°C for 6 hours to obtain a montmorillonite suspension with a concentration equal to 5wt%, and set aside;

[0037] (2) dissolving industrial grade polyvinylidene fluoride (PVDF) in chemically pure N,N-dimethylformamide to make a concentration equal to 20wt% polyvinylidene fluoride solution;

[0038] (3) Mix the above polyvinylidene fluoride solution and montmorillonite suspension evenly at a mass ratio of 17:12, pour and volatilize the solvent at a temperature of 100°C to prepare a polyvinylidene fluoride polarizable film, in which the montmorillonite The soil content was 15 wt%, and the film thickness was 0.01 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com