Large-span efficient multifunctional concrete sloping surface masonry machine

A multi-functional, concrete technology, applied in construction, irrigation pipelines, applications, etc., can solve the problems that concrete is not easy to vibrate and compact, the effect of surface slurry is not good, and affects the compactness of concrete, etc., to achieve continuous and compact feeding and distribution process , The effect of surface pulping is good, and the effect of reducing aggregate separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

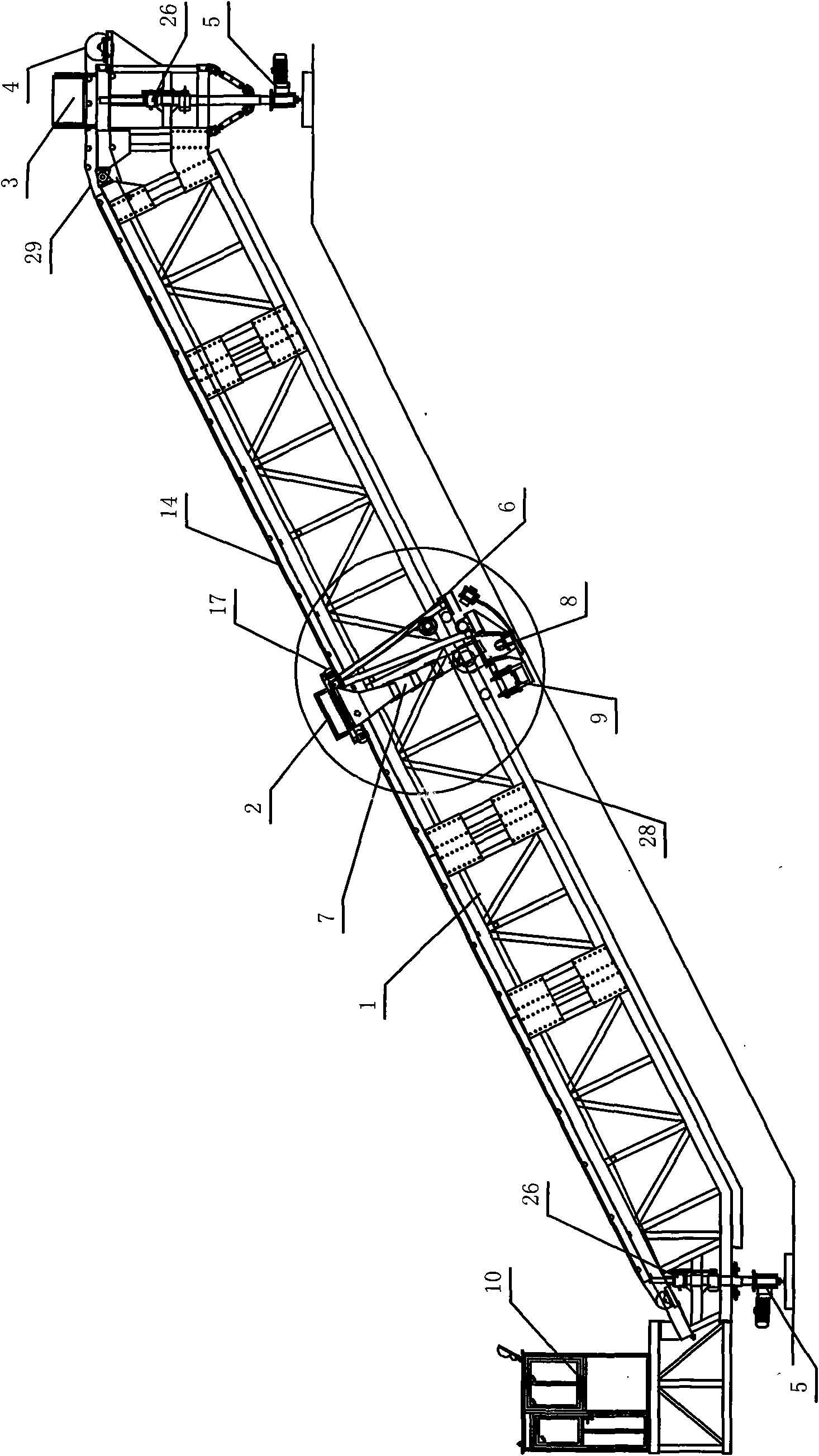

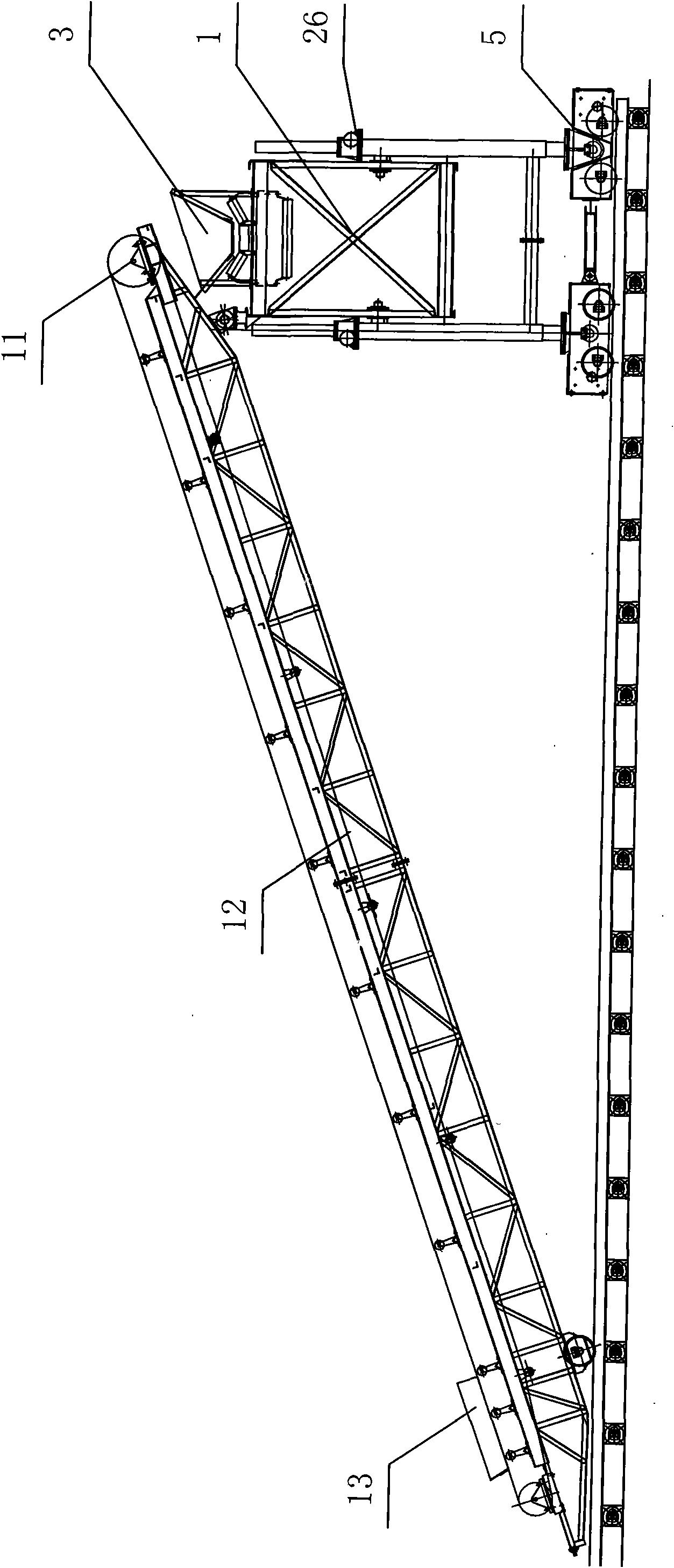

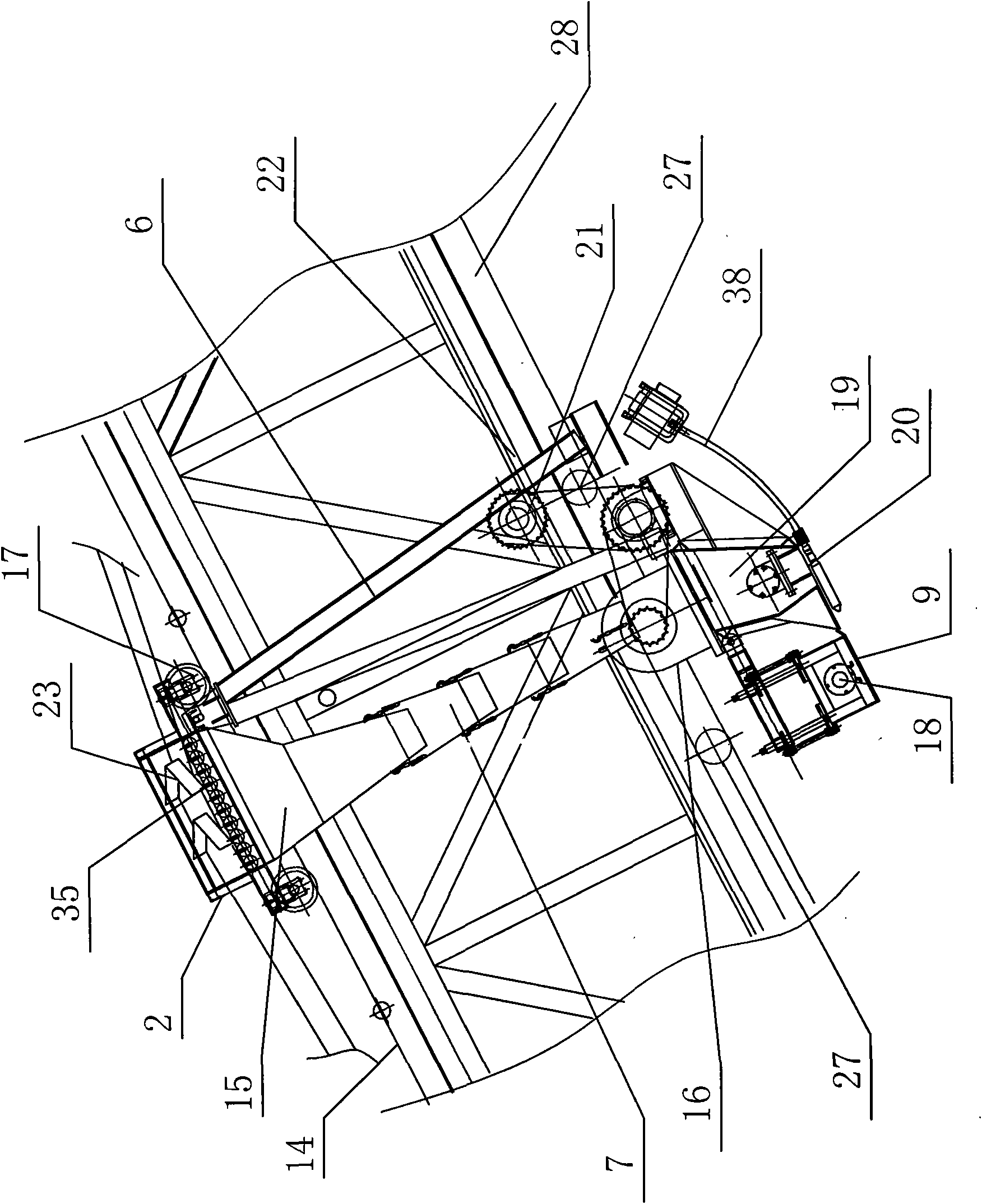

[0047] as attached figure 1 As shown, the present invention includes a main truss 1, a traveling mechanism 5 arranged at both ends of the main truss, a main receiving hopper 3 arranged at the top of the main truss 1, an electrical operation room 10 arranged at the bottom of the main truss 1, and a The main belt conveyor 4 and the conveying belt 29, the upper unloading vehicle 2 and the lower unloading vehicle 8 arranged on the main truss 1, the conveying system arranged on the upper unloading vehicle 2 and the lower unloading vehicle 8, The molding system on the feeding cart 8, as attached image 3 , 4 , 8, 9, 17, and 18, the forming system includes 10 vibrating bars 38 arranged horizontally at the lower end of the horizontal hinge cage 25 in the silo 19 and the silo outlet 20, arranged on the vibrating bar The sliding form 9 at the rear end of the 38 constitutes, the vibrating rod 38 is fixed on the lower end of the feed bin 19 by a clamp 39, the vibrating rod 38 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com