Jet engine

A jet engine and compressor technology, applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve the problems of complex engine structure and control system, reduced structure and strength reliability, and reduced aerodynamic stability, etc., to achieve Simplified engine structure, widened working range, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

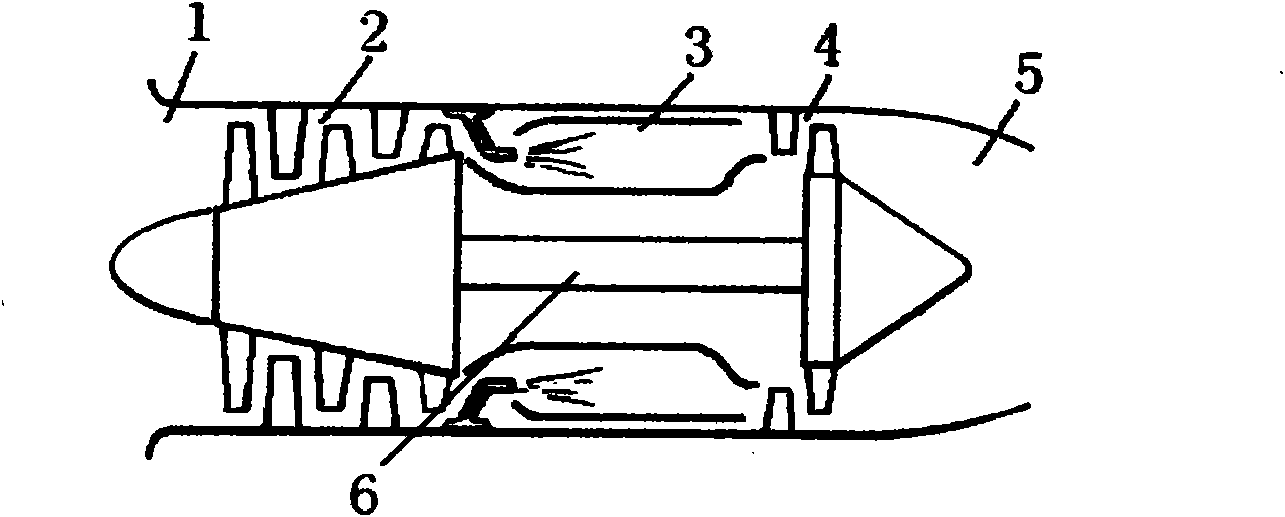

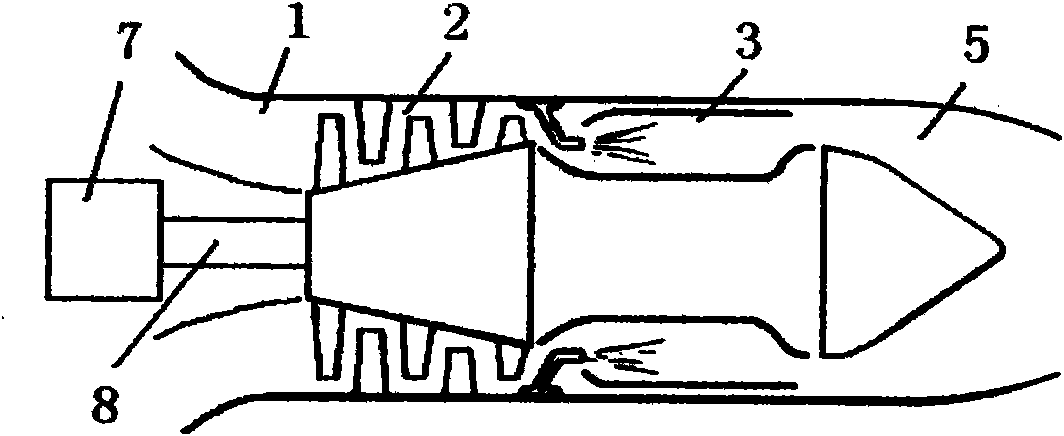

[0022] The jet engine of the present embodiment is made up of inlet duct (1), compressor (2), combustion chamber (3), tail nozzle (5) and independent power unit (7), and independent power unit (7) is a A gas turbine device is installed on the inlet side of the compressor (2), and its power output shaft (8) is connected with the compressor (2), and the compressor (2) adopts an axial flow compressor.

Embodiment 2

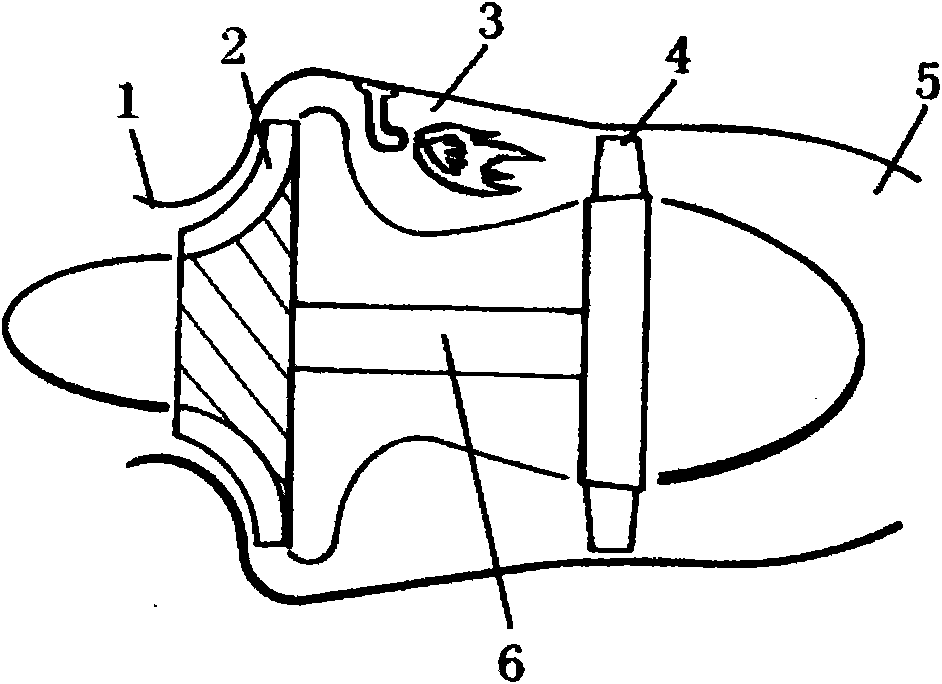

[0024] The jet engine of the present embodiment is made up of intake passage (1), air compressor (2), combustion chamber (3), tail pipe (5) and independent power unit (7), and independent power unit (7) is triangular The rotary engine is installed on the outlet side of the compressor (2), and its power output shaft (8) is connected with the compressor (2), and the compressor (2) adopts an axial flow compressor.

Embodiment 3

[0026] The jet engine of the present embodiment is made up of intake passage (1), air compressor (2), combustion chamber (3), tail nozzle (5) and independent power unit (7), and independent power unit (7) is reciprocating The piston engine is installed on the inlet side of the air compressor (2), and its power output shaft (8) is connected with the air compressor (2), and the air compressor (2) adopts a radial flow air compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com