Hot liquid injection multi-unit vapor compression device and heat pump

A vapor compression and multi-unit technology, applied in the field of compressors and heat pumps, can solve problems such as temperature rise, environmental pollution, and limited use range, and achieve the effect of high boost ratio and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

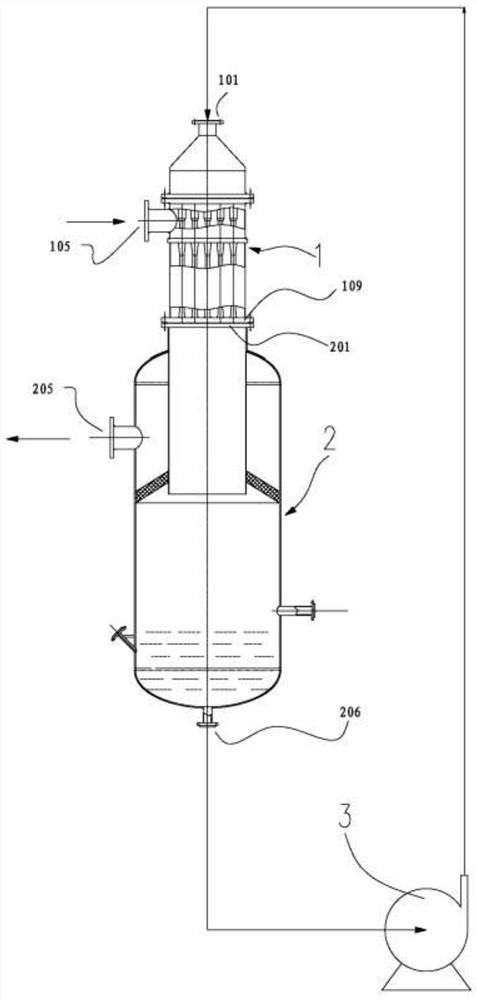

[0116] Such as figure 1 As shown, the present invention provides a thermal liquid injection multi-unit vapor compression device, the thermal liquid injection multi-unit vapor compression device comprises a thermal liquid injection multi-unit vapor compressor 1, a secondary expansion separation chamber 2, a thermal liquid cycle The booster pump 3; the hot liquid injection multi-unit vapor compressor 1 has a booster cycle hot liquid inlet 101, a low-grade steam or secondary steam inlet 105, and a flower plate 109 at the outlet of the multi-compression unit; the two-stage expansion separation Chamber 2 has an inlet 201 for two-phase flow, a hot liquid outlet 206, and a pressurized saturated vapor outlet 205;

[0117] The supercharged hot liquid outlet of the hot liquid circulation booster pump 3 communicates with the hot liquid inlet 101 of the hot liquid injection multi-unit vapor compressor 1; the low-grade steam or secondary The steam inlet 105 communicates with the low-grade...

Embodiment 2

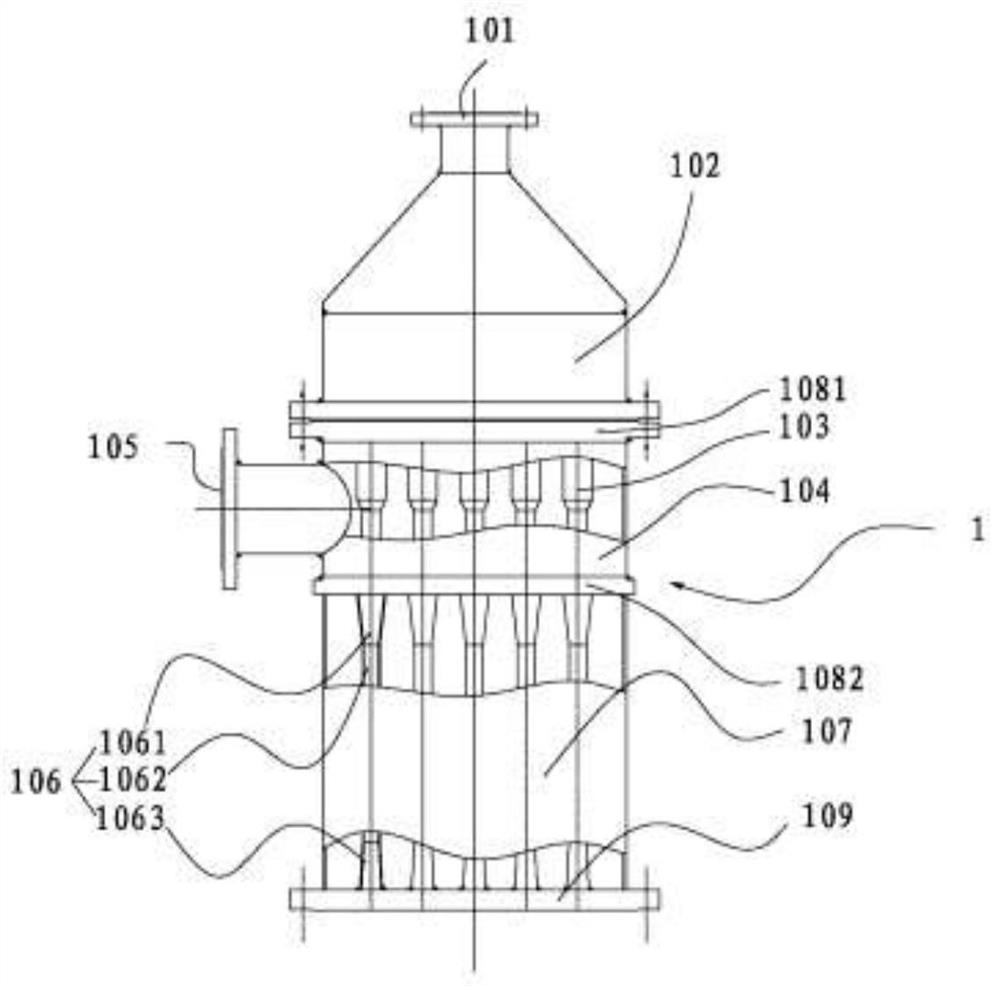

[0123] Such as figure 2 As shown, the thermal liquid injection multi-unit vapor compression device includes a thermal liquid injection multi-unit vapor compressor 1, a secondary expansion separation chamber 2, and a hydrothermal circulation booster pump 3; the thermal liquid injection multi-unit vapor compressor 1. It includes a liquid chamber 102 with a conical head or an elliptical head and a cylindrical inner cavity, a gas-liquid mixing chamber 104 with a cylindrical inner cavity, an upper flower plate 1081, and a lower flower plate 1082, and a cylindrical inner cavity And the multi-compression unit chamber 107 with the flower plate 109 of the multi-compression unit outlet at the bottom;

[0124] The conical head or oval head of the liquid chamber 102 is provided with a pressurized circulation hot liquid inlet 101; the upper flower plate 1081 of the gas-liquid mixing chamber 104 is equipped with a plurality of nozzles 103, and the number of nozzles 103 is ≥ 2 And communic...

Embodiment 3

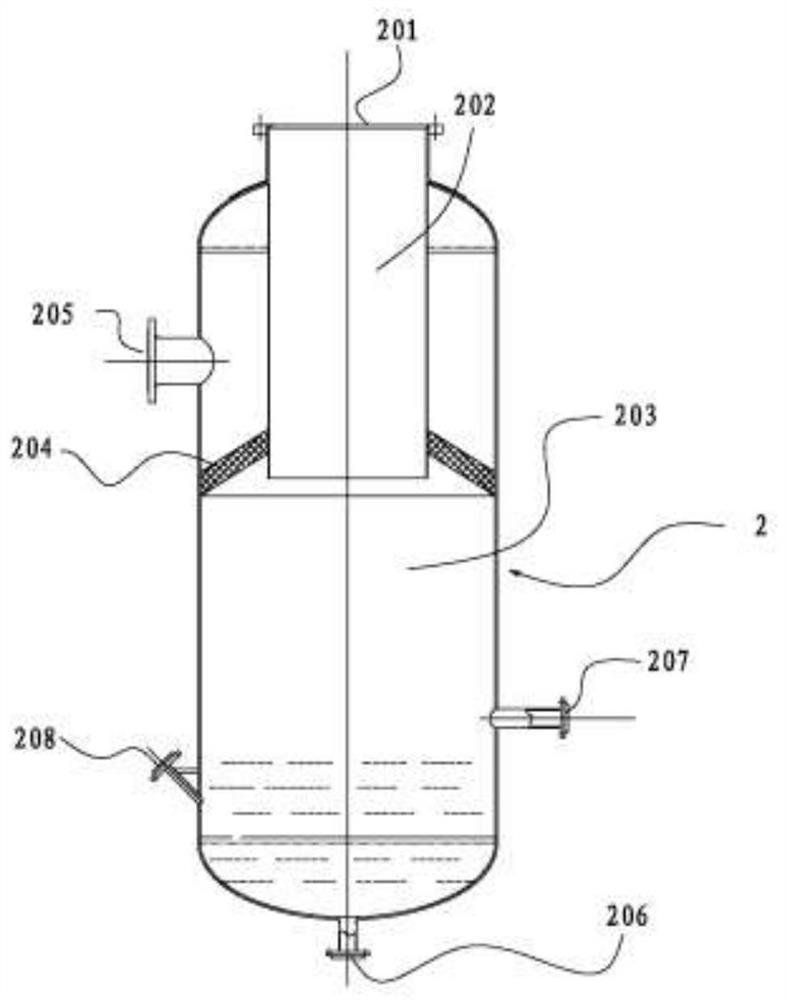

[0130] Such as image 3 As shown, the thermal liquid injection multi-unit vapor compression device includes a thermal liquid injection multi-unit vapor compressor 1, a secondary expansion separation chamber 2, and a hydrothermal circulation booster pump 3; the secondary expansion separation chamber 2 includes A first-stage expansion separation chamber 202 with a cylindrical inner cavity, a second-stage expansion separation chamber 203 with an upper oval head or a butterfly head, a lower oval head or a butterfly head, and a cylindrical inner cavity, There is an umbrella-shaped wire mesh demister 204 between the inner wall of the cylindrical inner cavity of the second-stage expansion separation chamber 203 and the outer wall of the cylindrical inner cavity of the first-stage expansion separation chamber 202;

[0131] The upper end of the first stage expansion separation chamber 202 has a two-phase flow inlet 201, and the lower end has the outlet of the first stage expansion sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com