Method and system for detaching a plurality of ceramic components from a component block

A component, ceramic technology, used in the field of separating multiple ceramic components and systems from the component block, can solve the problems of shortened saw wire life, high mechanical load, complex construction, etc., to achieve extended life, low cost, and small wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

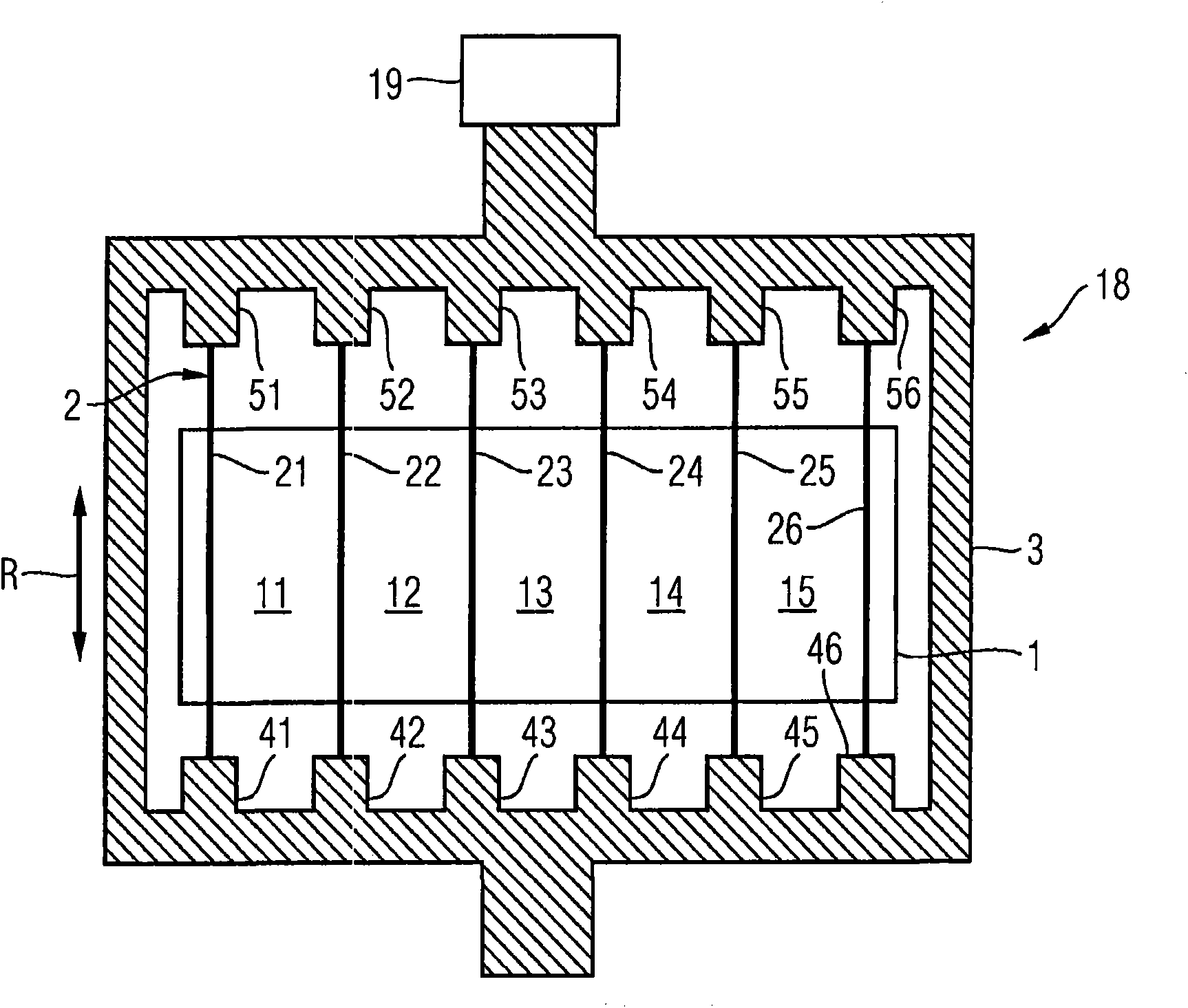

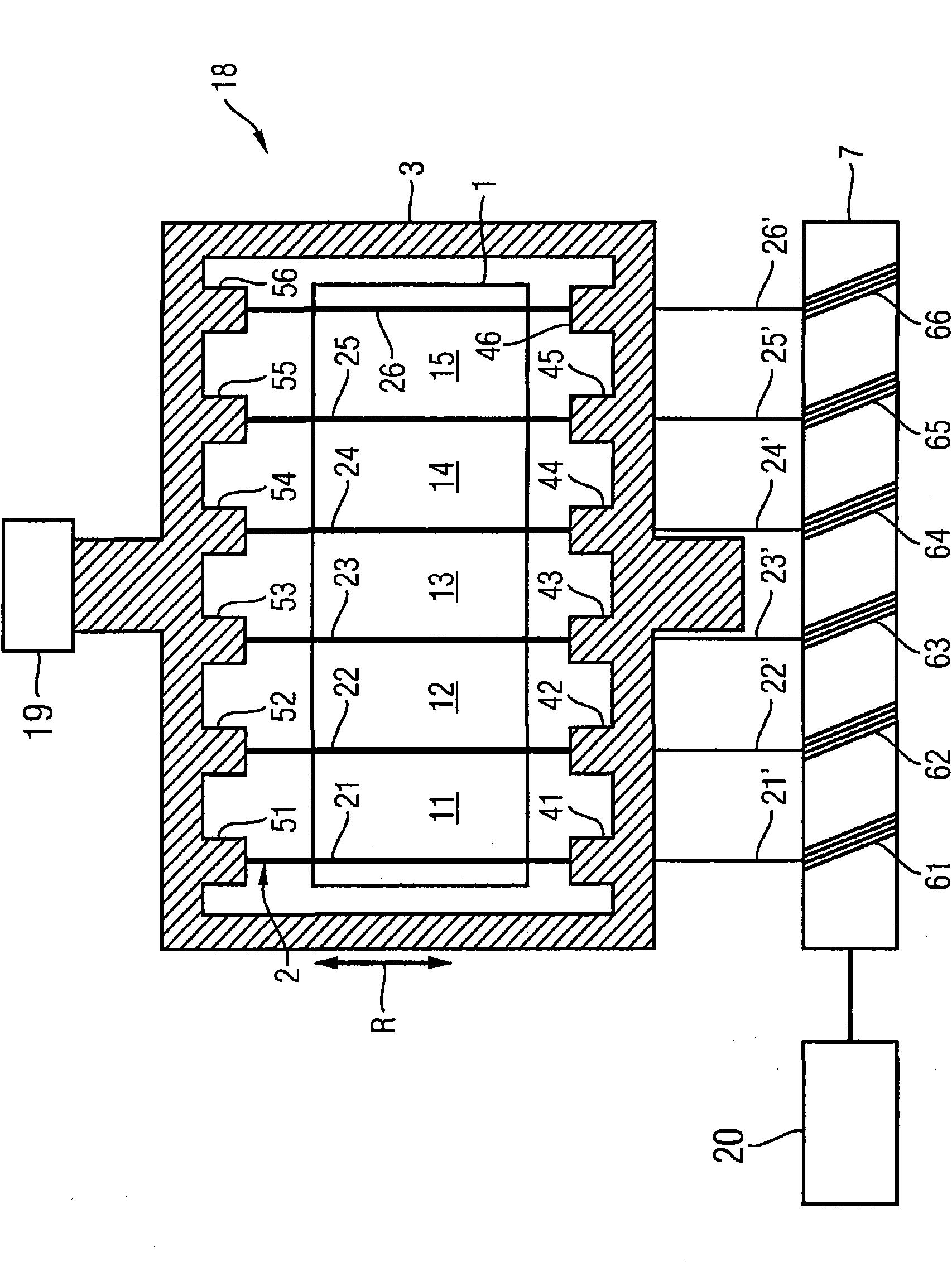

[0043] exist figure 1 A schematic block diagram of a first embodiment of a system 18 for separating a plurality of ceramic components 11 - 15 from a ceramic component block 1 is shown in . The system 18 has a saw frame 2 and an actuator 19 . The saw frame 2 has a plurality of parallel wire segments 21 - 26 clamped in the frame 3 . The actuator 19 drives the saw frame 2 in order to saw the component block 1 into a plurality of components 11-15 or to move the saw frame 2. here, figure 1 The reference sign R in shows the sawing direction. Without limiting the generality, in figure 1 Six line segments 21-26 are shown in . However, the number of segments 21-26 clamped in block 3 may be any number. In addition, in figure 1 Also shown is a component block 1 or green block having a cuboid shape. This shape of the green block or component block is also only exemplary, any other shape is conceivable.

[0044] The frame 3 preferably has two opposing wire tensioners 41-46; 51-56 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com