Spring loading connector

A technology of connectors and adapters, applied in the direction of connection, two-pole connection, two-part connection device, etc., can solve the problems of radial offset limitation, unfavorable modularization and miniaturization design, large radio frequency leakage, etc., to achieve Prevent signal interference, reduce assembly cost, and effect of small radio frequency leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

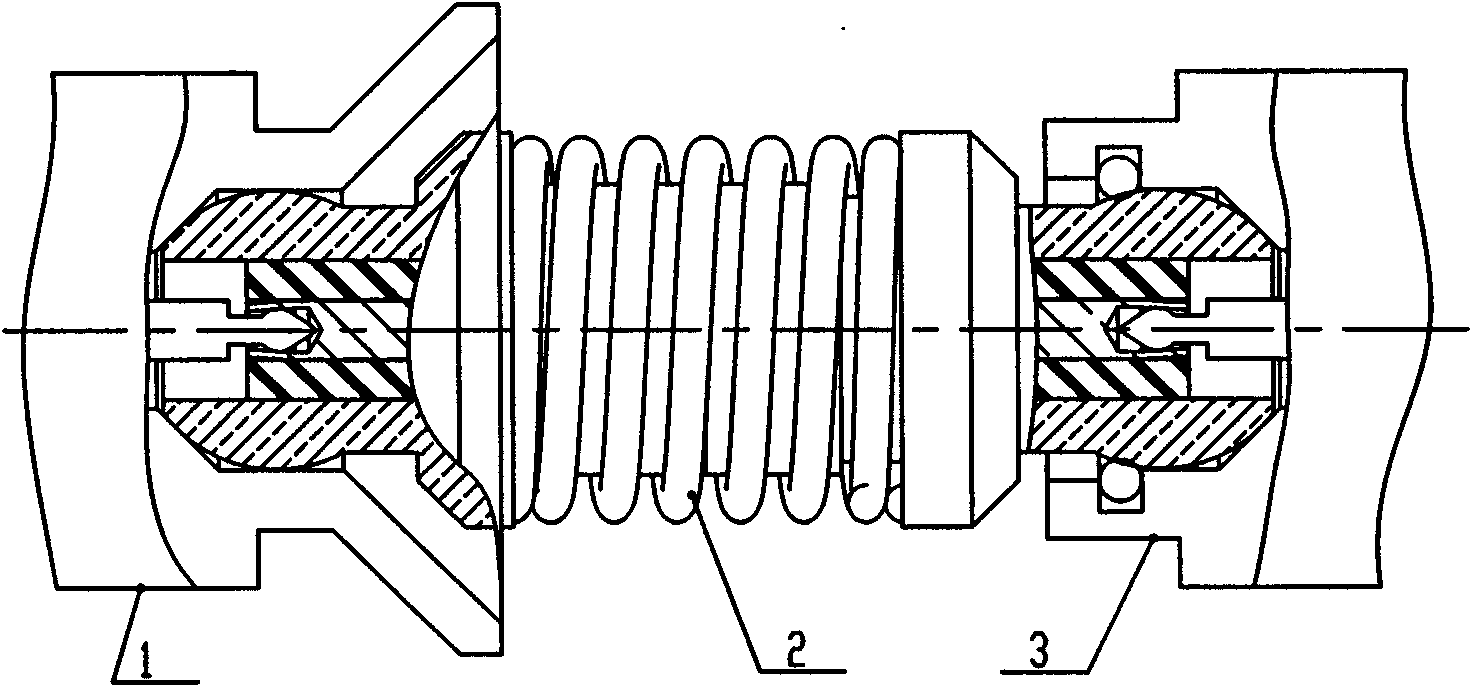

[0037] The present invention will be described in detail below by referring to several non-limiting specific embodiments in conjunction with the accompanying drawings.

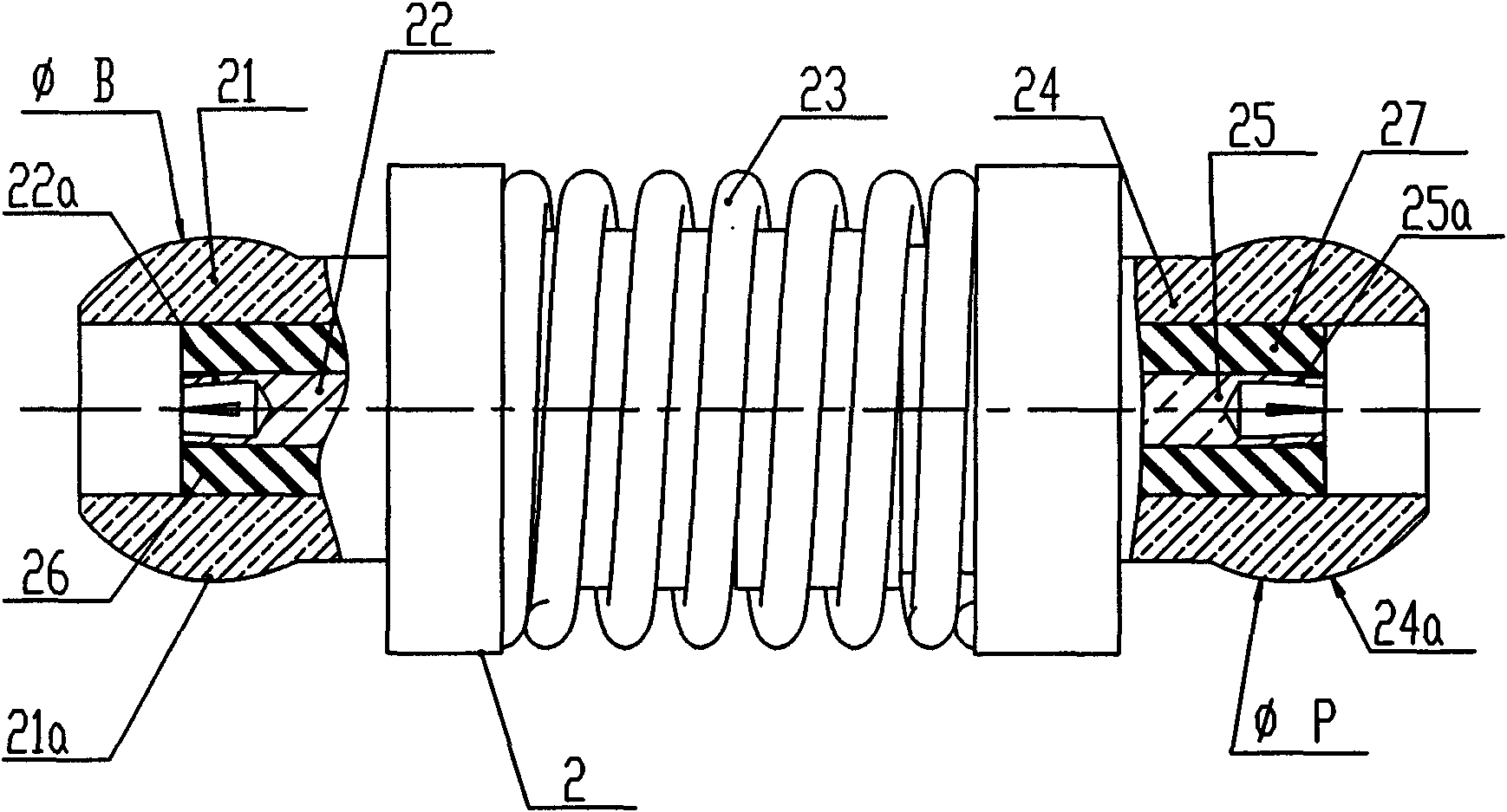

[0038] see Figure 1 to Figure 3 As shown, a spring-loaded connector includes a socket 1 and an adapter 2 mated with the socket 1 .

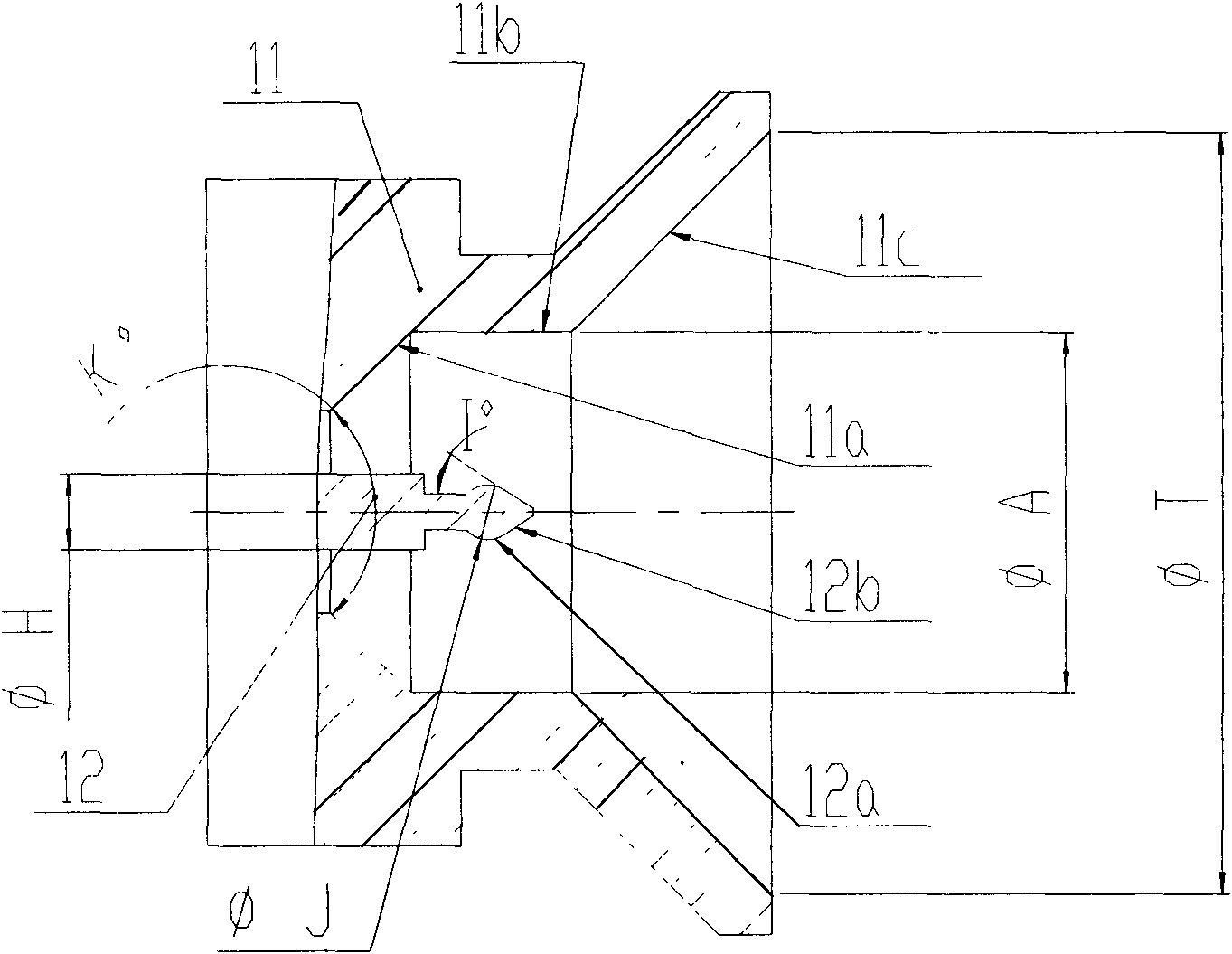

[0039] The socket 1 includes a housing 11 and a central conductor 12 installed at the center of the housing. The inner surface of the housing of the socket 1 is divided into three sections, including a first conical surface 11c (that is, a bell mouth structure for guiding), a second conical surface 11a and a cylindrical surface 11b between the two conical surfaces. The diameter A of the cylindrical surface in the inner surface of the housing of the socket is 6-7mm. The diameter A of the cylindrical surface 11 b in the housing inner surface of the socket is 0-1 mm larger than the maximum diameter B of the insertion end of the adapter housing 21 . The taper K of the second coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com