Organic tungsten complexes

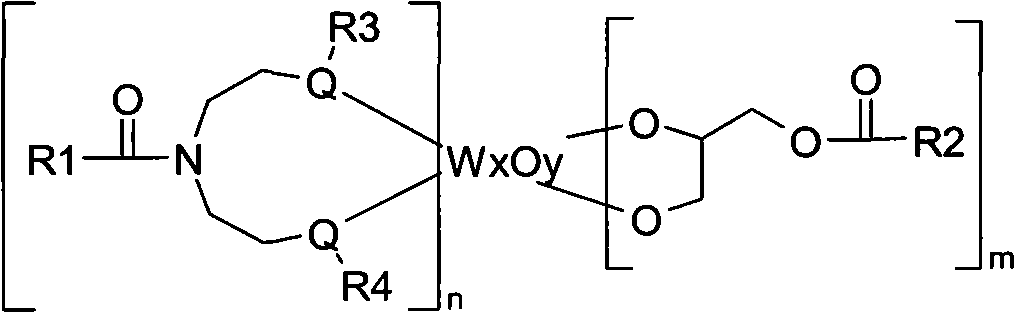

一种配合物、有机钨的技术,应用在有机化学、润滑组合物、没有C-金属键的6/16组有机化合物等方向,能够解决未例示含有有机钨配合物的润滑组合物、没有证实形成配合物数据等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The organic tungsten complex of the embodiment of the present invention was prepared as follows. 99.84 g of OD-896NT (a fatty derivative of 2-(2-aminoethyl)amino-ethanol, available from R.T. Vanderbilt Co. Inc.) was added to the reaction vessel and stirred at 60°C. To this was added 24.92 g of tungstic acid followed by 25.1 g of a 28.2% ammonium hydroxide solution. The pressure in the reaction vessel was maintained at 1 psi to 2 psi for 30 minutes by controlled gas venting. The reaction was maintained at 60°C for a total of 2.5 hours. The solvent was then removed by slowly applying a vacuum of 30 mm Hg while heating to 120°C to 130°C. The reaction mixture was maintained in this temperature range under vacuum until all the reaction solvent and water were removed. The product was then filtered through celite and recovered to give 61.8 g of an amber oil. Elemental analysis: C=60.4%, H=10.9%, N=3.4%, W=7.5% (with WO 3 meter, ash content = 9.5%).

Embodiment 2

[0091] Organotungsten complexes were prepared as the reaction product of the ammonium salt of tungstic acid with OD-896NT (an aliphatic derivative of 2-(2-aminoethyl)amino-ethanol, available from R.T. Vanderbilt Co. Inc.). The molar ratio of OD-896NT to tungsten is 2:1. The analysis of the amber oil is as follows: elemental analysis: C=63.0%, H=10.8%, N=3.8%, W=9.2% (in WO 3 meter, ash content = 11.7%).

Embodiment 3

[0093] As ammonium salt of tungstic acid and OCD-277 (≥90% 摩尔 Fatty derivatives of 2-(2-aminoethyl)amino-ethanol, ≤10% 摩尔 1-(2-Hydroxyethyl)-2-2-(tall oil alkyl)-2-imidazoline), a reaction product purchased from R.T.Vanderbilt Co.Inc.) to prepare organic tungsten complexes. The molar ratio of OCD-277 to tungsten was 6.5:1. The analysis of gained amber oil is as follows: elemental analysis C=64.2%, H=9.1%, N=3.6%, W=6.0% (in WO 3 , ash content = 7.6%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com