Crystal oscillator piece and method for manufacturing the same

一种制造方法、振子片的技术,应用在半导体/固态器件制造、压电/电致伸缩器件的制造/组装、压电器件/电致伸缩器件等方向,能够解决破坏平衡、漏振等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The crystal vibrator piece and its manufacturing method according to the present invention will be described below with reference to the drawings. However, the technical scope of the present invention is not limited to these embodiments, and attention should be paid to the inventions described in the technical scope of the present invention and their equivalents.

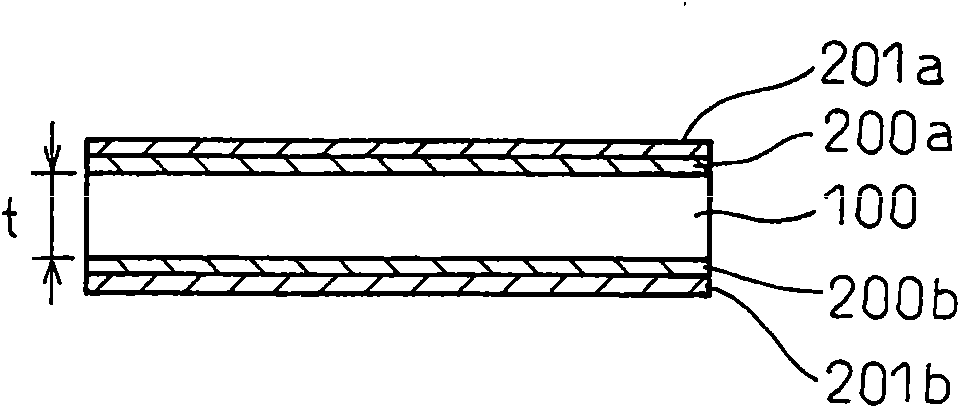

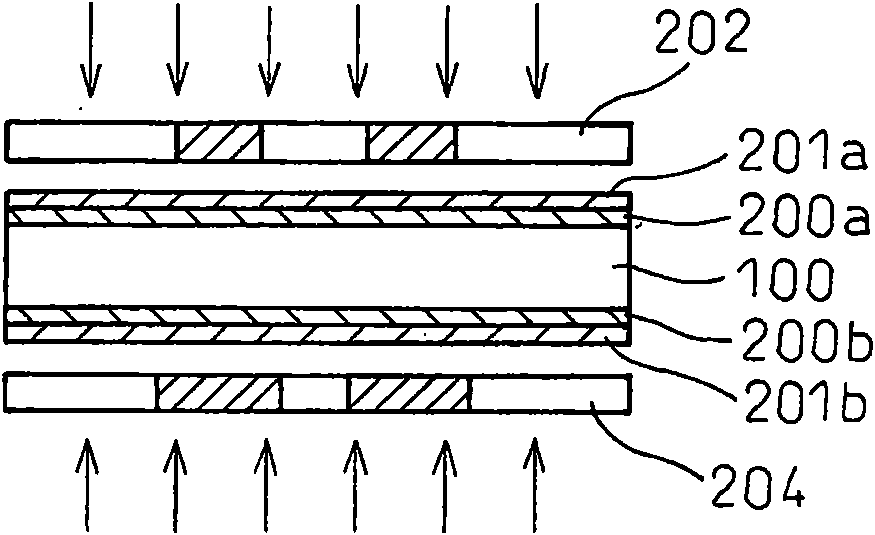

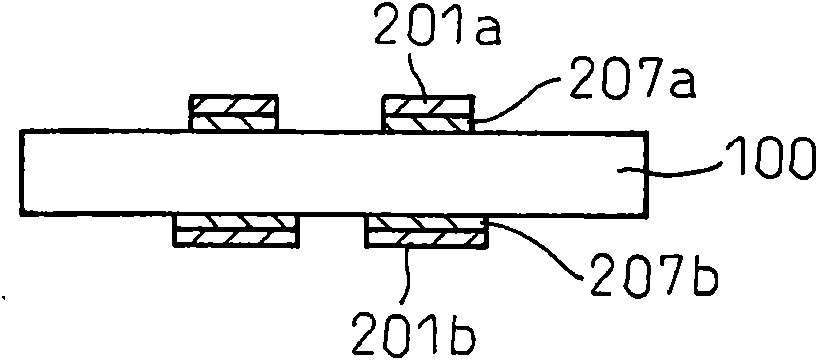

[0085] First, a method of manufacturing a crystal resonator piece according to the present invention will be described using FIG. 1 .

[0086] FIG. 1( a ) shows a state in which metal corrosion-resistant films 200 a and 200 b are formed by sputtering, vapor deposition, electroplating, or the like on both surfaces of a crystal wafer 100 whose plate thickness is adjusted to t. The metal corrosion-resistant films 200a and 200b use Cr as the bottom layer and Au as the surface layer. Furthermore, photoresists 201a, 201b are formed on the surfaces of the metal corrosion-resistant films 200a, 200b, respectively.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com