Method and formula for forming hyper branched polymer

A branched polymer and polymer technology are applied in the formulation of hyperbranched polymers and the field of formation thereof, which can solve the problem of ineffective control of molecular structure and molecular weight, increase of preparation process steps and complexity, and hyperbranched polymerization. The problem of low product yield, etc., achieves the effects of excellent processing performance, reduced production cost, and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

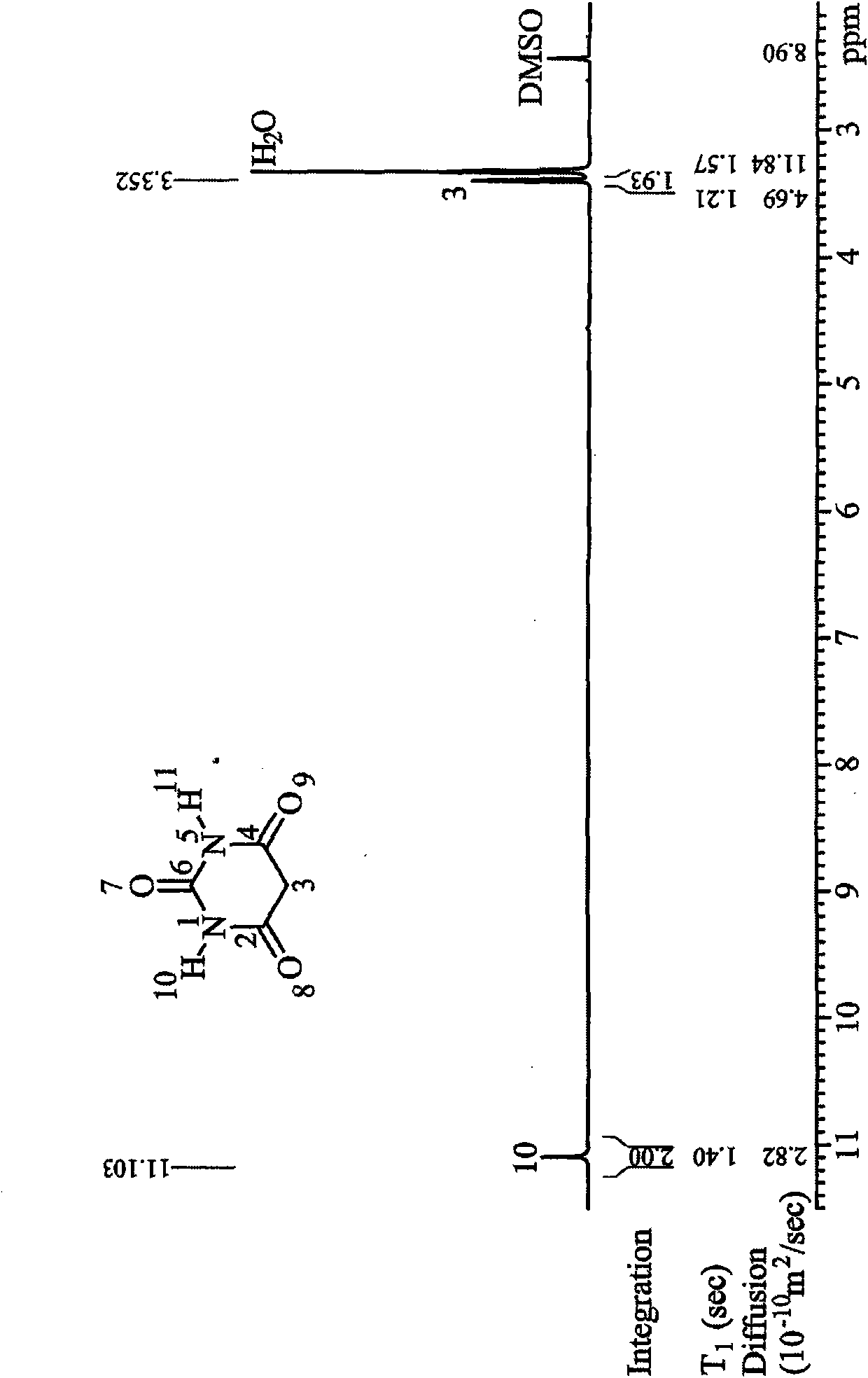

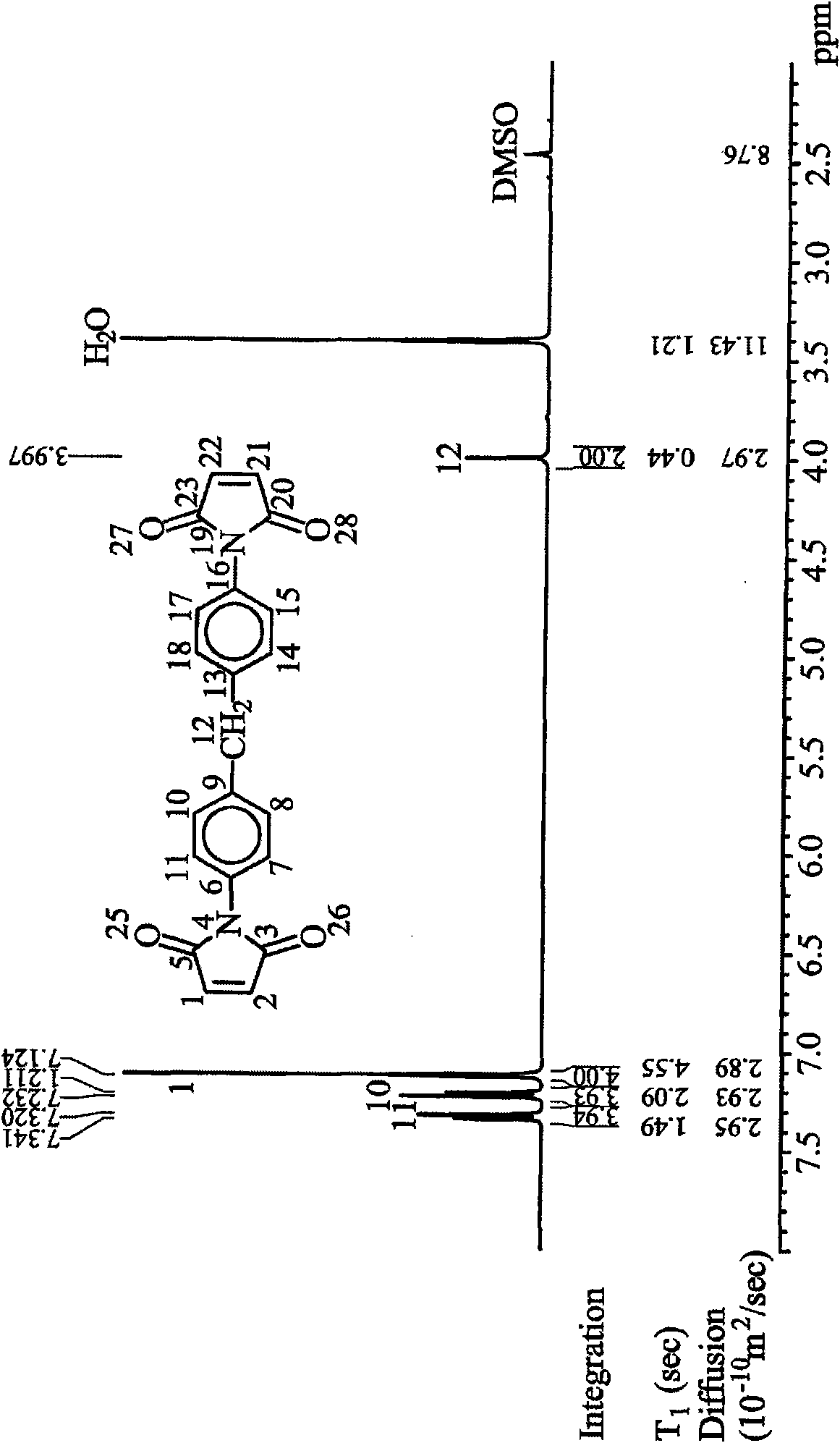

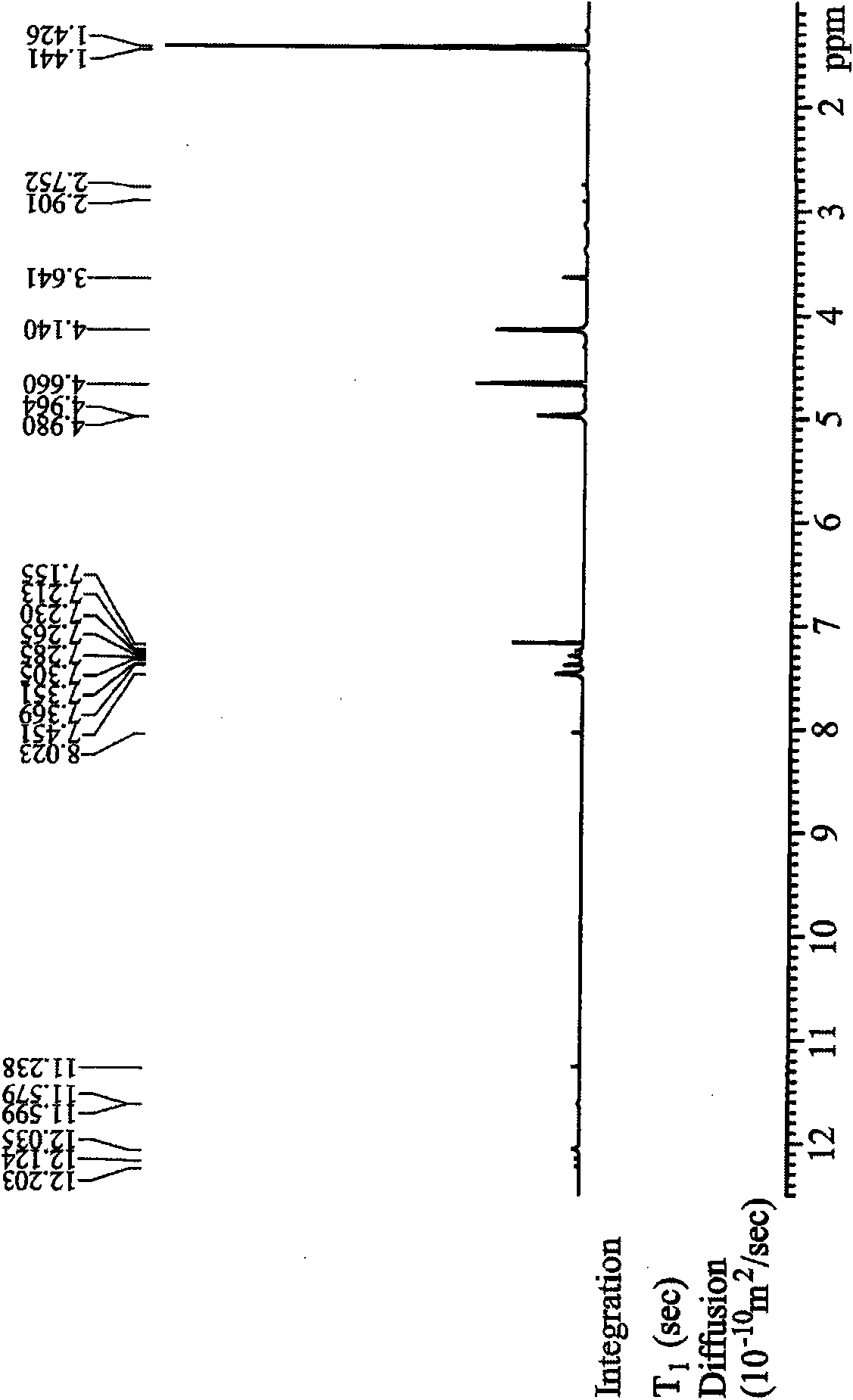

[0065] Example 1: STOBA (1:1)-GBL-20wt%-90°C-6H

[0066] STOBA (self-terminated oligomer with hyper-branched architecture) refers to self-terminated hyper-branched oligomer. STOBA(1:1)-GBL-20wt%-90°C-6H means that the molar ratio of the reactant BMI to BTA is 1:1, the solid content is about 20wt.%, the solvent is the GBL system, and the reaction is at 90°C for 6 hours ; The program steps and reaction conditions of its preparation are listed as follows:

[0067] (1) Take about 18 grams of bismaleimide (4,4'-Bismaleimidodi-phenylmethane) monomer into a 250ml round-bottomed three-neck bottle, add about 60 grams of GBL solvent, and heat to 90 ° C to fully stir , so that the bismaleimide monomer can be completely dissolved in the GBL solvent.

[0068] (2) Weigh about 7 grams of BTA powder, add about 40 grams of GBL solvent, and fully stir with a magnet, so that BTA can be evenly dispersed in the GBL solvent.

[0069] (3) Divide the BTA-GBL milky solution into 8 equal parts of th...

Embodiment 2

[0072] Example 2: STOBA (1:1)-NMP-20wt%-70°C-6H

[0073] STOBA(1:1)-NMP-20wt%-70°C-6H means that the molar ratio of the reactant BMI to BTA is 1:1, the solid content is about 20wt.%, the solvent is NMP system, and the reaction is at 70°C for 6 hours ; The program steps and reaction conditions of its preparation are listed as follows:

[0074] (1) Take about 18 grams of bismaleimide (4,4'-Bismaleimidodi-phenylmethane) monomer and put it into a 250ml round-bottomed three-neck bottle, add about 60 grams of NMP solvent, and heat to 70°C and stir thoroughly , so that the bismaleimide monomer can be completely dissolved in the NMP solvent.

[0075] (2) Weigh about 7 grams of BTA powder, add about 40 grams of NMP solvent, and fully stir with a magnet, so that BTA can be evenly dispersed in the NMP solvent.

[0076] (3) Divide the BTA-NMP emulsion solution into 8 equal parts to add the material, add the material every 15 minutes, and gradually add it to the BMI-NMP solution at 70°C ...

Embodiment 3

[0079] Example 3: STOBA (1:1)-DMF-20wt%-40°C-20H

[0080] STOBA(1:1)-NMP-20wt%-40°C-6H means that the molar ratio of the reactant BMI to BTA is 1:1, the solid content is about 20wt.%, the solvent is DMF system, and the reaction is at 40°C for 20 hours ; The program steps and reaction conditions of its preparation are listed as follows:

[0081] (1) Put about 18 grams of bismaleimide (4,4'-Bismaleimidodi-phenylmethane) monomer into a 250ml round-bottomed three-neck bottle, add about 60 grams of DMF solvent, and heat to 40°C and stir thoroughly , so that the bismaleimide monomer can be completely dissolved in the DMF solvent.

[0082] (2) Weigh about 7 grams of BTA powder, add about 40 grams of DMF solvent, and fully stir with a magnet, so that BTA can be evenly dispersed in DMF solvent.

[0083] (3) Divide the BTA-DMF emulsion solution into 8 equal parts of the additive, add the material once every 15 minutes, and gradually add it to the BMI-DMF solution at 40°C in batches an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com