Device for filtering sand-containing viscous liquid

A filter device and viscous liquid technology, applied in the components of pumping devices for elastic fluids, gravity filters, liquid fuel engines, etc., can solve the problems of pump wear, heavy crude oil obstruction, etc., and achieve the function of maintaining blocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

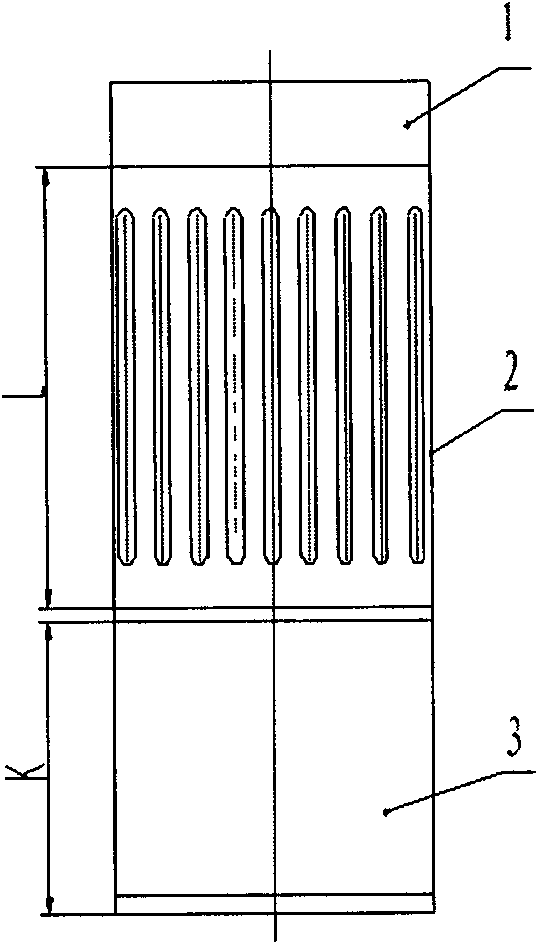

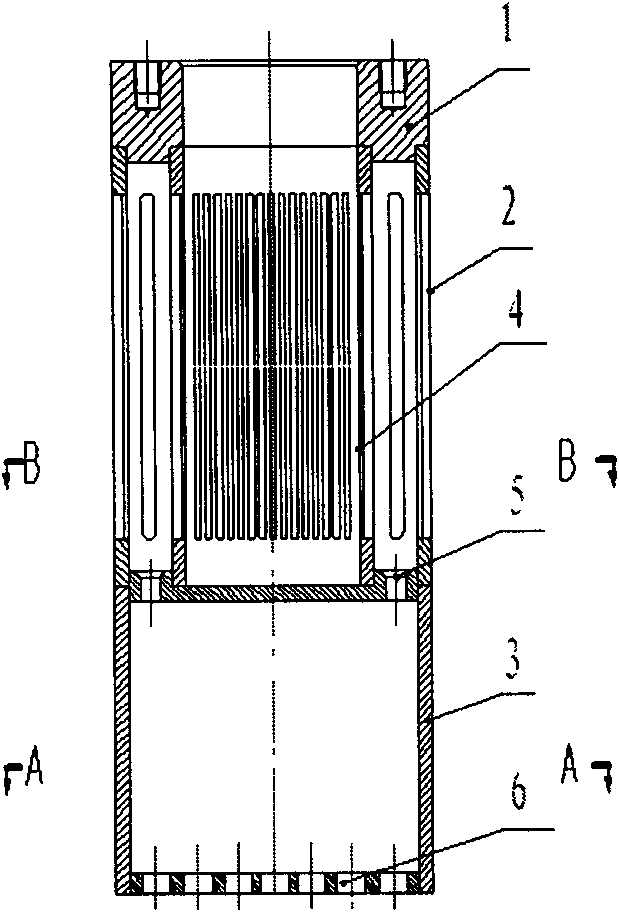

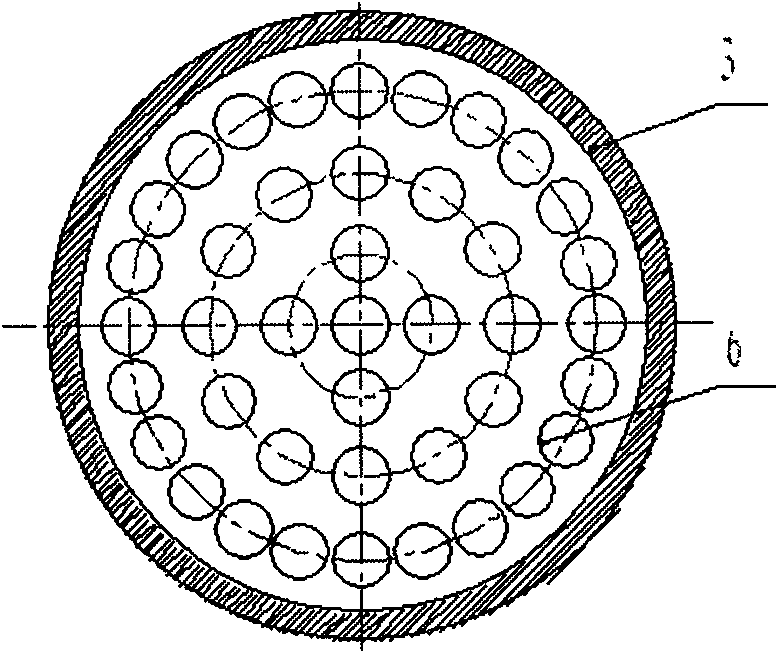

[0017] A filter device for viscous liquids containing sand. The structure of the device is as figure 1 , figure 2 As shown, it consists of an upper joint 1, an inner filter cartridge 4, an outer filter cartridge 2 and a lower sleeve 3. The upper end and the lower end of the lower sleeve 3 are fixedly equipped with a middle joint 5 and a lower joint 6 respectively, and the ratio of the length K of the lower sleeve 3 to the length L of the inner filter cartridge 4 and the outer filter cartridge 2 is 1: (1.5~2) ; The lower joint 6 such as image 3 As shown, there are 41 small holes evenly arranged on the circular plane, and the middle joint is as follows figure 2 and Figure 4 Shown, be evenly provided with a circle of 20 apertures on the raised garden ring.

[0018] Such as figure 2 As shown, the two ends of the inner filter cartridge 4 are fixedly installed on the inner surface of the raised part of the upper joint 1 and the middle joint 5 respectively, and the two end...

Embodiment 2

[0022] A filter device for viscous liquids containing sand. The ratio of the length K of the lower sleeve 3 of the device to the length L of the inner filter cartridge 4 and the outer filter cartridge 2 is 1: (2.5 to 3), and 10 to 40 small holes are evenly arranged on the circular plane of the lower joint 6. Holes, a circle of 10 to 20 small holes is evenly arranged on the raised ring of the middle joint. The filter holes of the inner filter cartridge 4 and the outer filter cartridge 2 are grid-shaped holes with an aspect ratio of (50-200): 1, and the installation gap between the inner filter cartridge 4 and the outer filter cartridge 2 is 5-35mm, and the outer filter cartridge The filter hole width of 2 is 5-8mm, the filter hole width of the inner filter cartridge 4 is 0.75-2mm; the diameter of the small holes on the lower joint 6 and the middle joint 5 is 5-8mm.

[0023] Other parts of this embodiment are the same as Embodiment 1.

Embodiment 3

[0025] A filter device for viscous liquids containing sand. The ratio of the length K of the lower sleeve 3 of the device to the length L of the inner filter cartridge 4 and the outer filter cartridge 2 is 1: (2 to 2.5), and 41 to 100 small holes are evenly arranged on the circular plane of the lower joint 6. Holes, a circle of 21 to 50 small holes is evenly arranged on the raised ring of the middle joint. The filter holes of the inner filter cartridge 4 and the outer filter cartridge 2 are grid-shaped holes with an aspect ratio of (200-700): 1, and the installation gap between the inner filter cartridge 4 and the outer filter cartridge 2 is 75-105mm, and the outer filter cartridge The filter hole width of 2 is 8-10mm, the filter hole width of inner filter cartridge 4 is 2-3mm; the small hole diameter on the lower joint 6 and the middle joint 5 is 3-4mm.

[0026] Other parts of this embodiment are the same as Embodiment 1.

[0027] This specific embodiment utilizes the essen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com