Flexible-connection gear box electro-hydraulic control valve for forklift

An electro-hydraulic control valve and soft connection technology, applied in transmission control, fluid pressure actuating device, components with teeth, etc., can solve the problem that the space around the gearbox body cannot be reasonably used, and increase the complexity of the control connection part. , large volume of electro-hydraulic control valve body, etc., to achieve the effect of easy comprehensive configuration, light weight and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

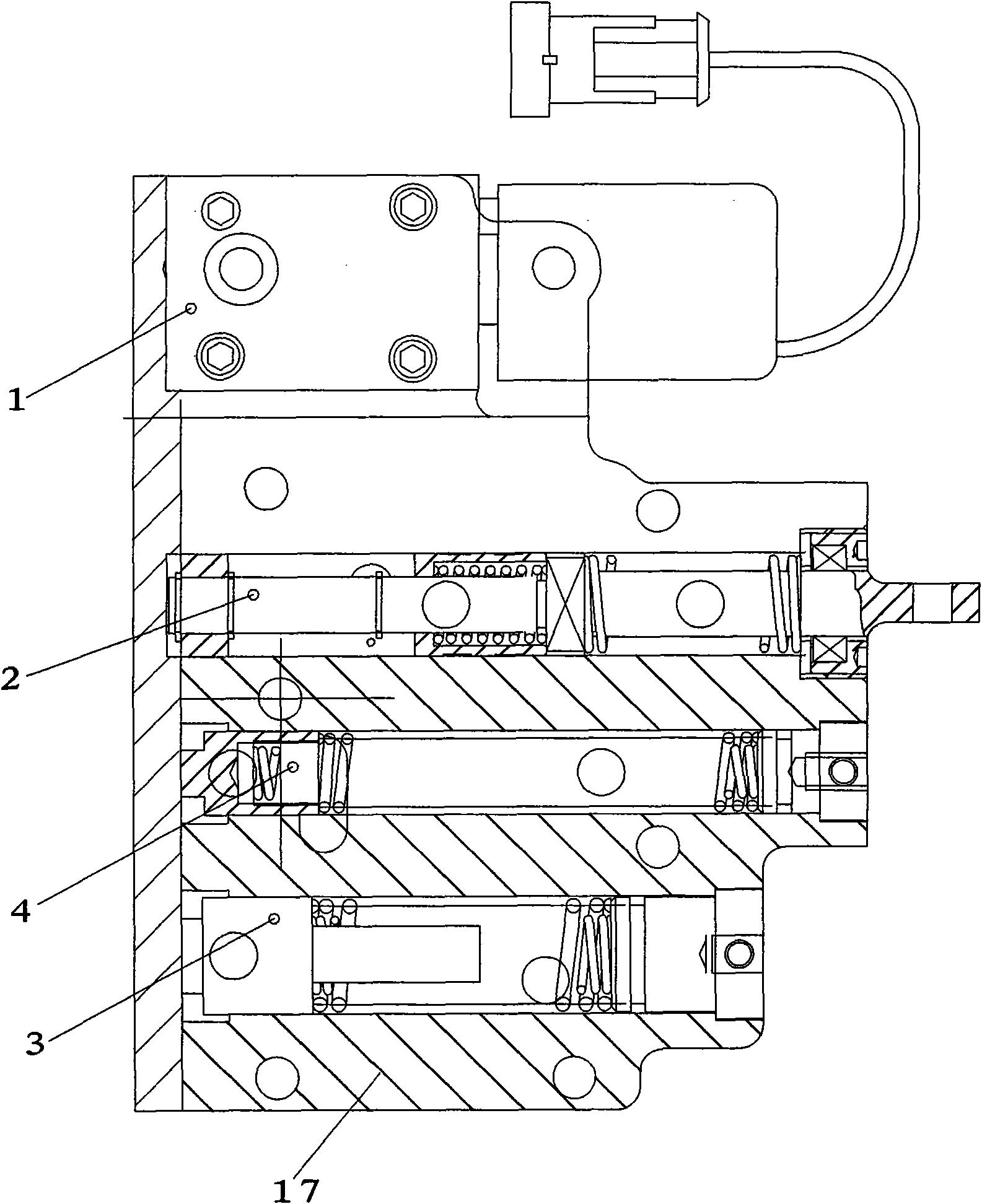

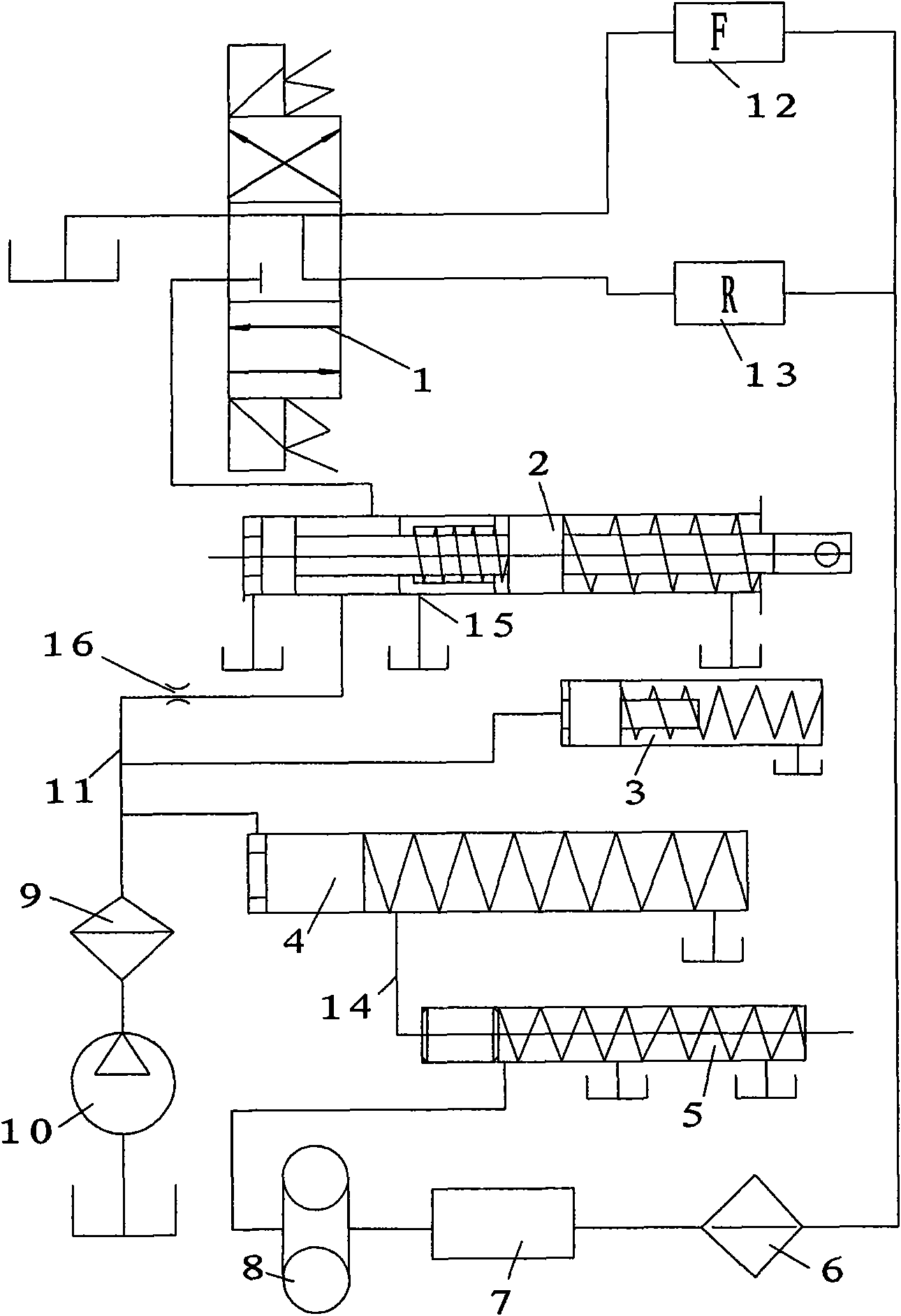

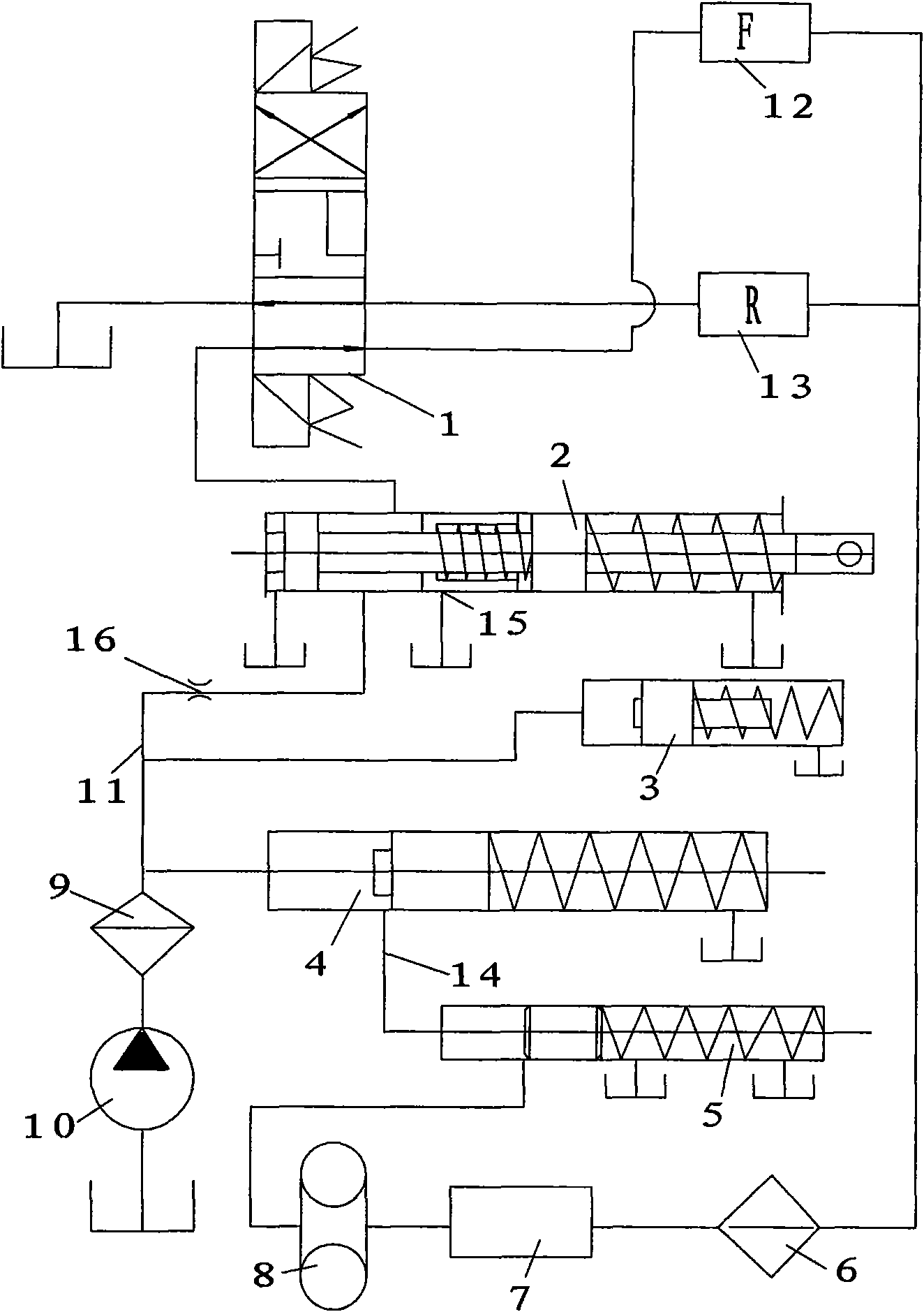

[0023] see figure 1 , figure 2 , in this embodiment, the reversing solenoid valve 1, the micro-motion valve 2, the energy storage valve 3 and the constant pressure valve 4 are integrated and integrated in a parallel manner at the plane interface installed outside the gearbox assembly; the oil circuit is set as : The main oil circuit 11 is connected to the oil circuit input port of the reversing solenoid valve 1 through the throttle valve 16 and the inching valve 2 in sequence, and the forward gear oil port of the reversing solenoid valve 1 is directly connected to the forward gear hydraulic clutch 12. The reverse gear oil port of the solenoid valve 1 is directly connected to the reverse gear hydraulic clutch 13; in the main oil circuit 11, on the side of the oil circuit inlet end of the inching valve 2, a constant pressure valve 4 and an energy storage valve 3 are respectively set .

[0024] figure 2 In the shown system, a gear pump 10 and a total oil filter 9 are also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com