Seaweed high-activity dietary fiber and production method thereof

The technology of seaweed dietary fiber and dietary fiber is applied in the field of dietary fiber, which can solve the problem of high production cost and achieve the effects of reducing production cost, ensuring expansion force, nutritional balance and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0020] The first specific embodiment of the present invention is a high-activity dietary fiber from seaweed. The dietary fiber uses the seaweed residue liquid produced in the production process of seaweed glue as a raw material, and takes the filter residue and the filtrate from the seaweed residue liquid respectively, and passes through The treatment process activates the filtrate to make soluble dietary fiber, and at the same time processes the filter residue to make insoluble dietary fiber, and then compound the insoluble dietary fiber and soluble dietary fiber to form seaweed highly active dietary fiber. During the compounding process, the ratio of the soluble dietary fiber to the insoluble dietary fiber is: 5%:95% by weight.

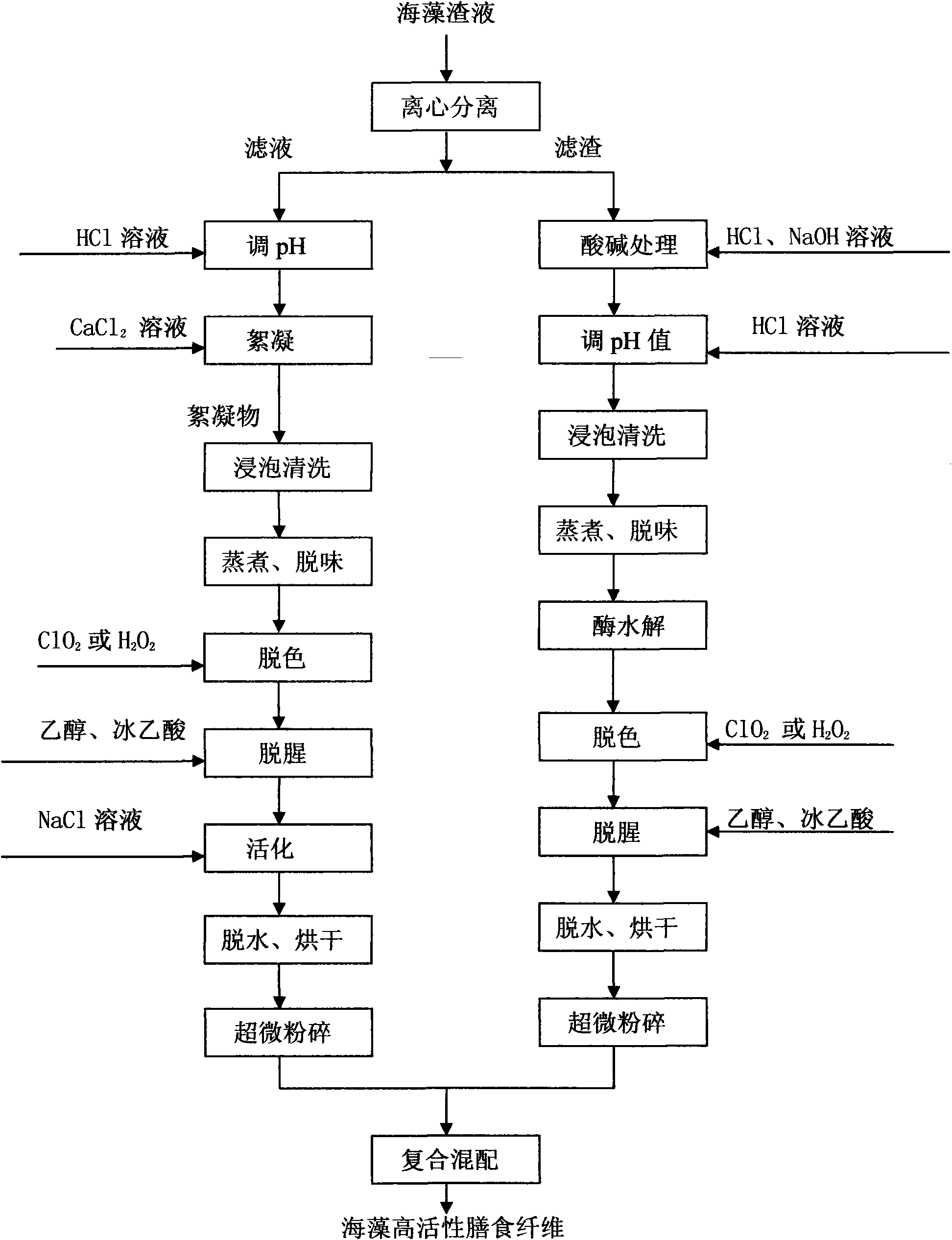

[0021] Such as figure 1 The production method of above-mentioned seaweed high activity dietary fiber shown, comprises the following steps:

[0022] 1) Centrifugal separation: the seaweed residue liquid in the production process of seaweed glue is c...

no. 2 Embodiment

[0032] The second specific embodiment of the present invention is a high-activity dietary fiber from seaweed. The dietary fiber uses the seaweed residue liquid produced in the production process of seaweed glue as a raw material, and takes the filter residue and the filtrate from the seaweed residue liquid respectively, and passes through The treatment process activates the filtrate to make soluble dietary fiber, and at the same time processes the filter residue to make insoluble dietary fiber, and then compound the insoluble dietary fiber and soluble dietary fiber to form seaweed highly active dietary fiber. During the compounding process, the ratio of soluble dietary fiber to insoluble dietary fiber is: 10%:90% by weight.

[0033] Such as figure 1 The production method of above-mentioned seaweed high activity dietary fiber shown, comprises the following steps:

[0034] 1) Centrifugal separation: the seaweed residue liquid in the production process of seaweed glue is centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com