Method for clarifying lily juice by enzymolysis

A technology of lily and juice, which is applied in the field of enzymatic hydrolysis and clarification of lily juice, which can solve the problems of loss of functional factors and loss of nutrient components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1, a kind of lily juice enzymolysis clarification method comprises the following steps,

[0074] 1) Check and select fresh lily balls that are free of impurities, mildew, and insect eyes, and separate the lily balls to remove impurities.

[0075] 2) Hot blanching and color protection Take water 15 times the weight of lily balls, add color protection agent, heat to 100°C, pour in lily ball petals, and blanch for 2.5 minutes. Lily color protection conditions are: sodium chloride 0.1g / kg, citric acid 0.1g / kg, sodium erythorbate 0.2g / kg.

[0076] 3) After crushing and cooling, pour the color protection liquid and lily petals into the crusher for crushing.

[0077] 4) Gelatinization Put the beaten lily juice into a water bath at 60° C. for heating and gelatinization for 20 minutes. Stir continuously during gelatinization to make it completely gelatinized.

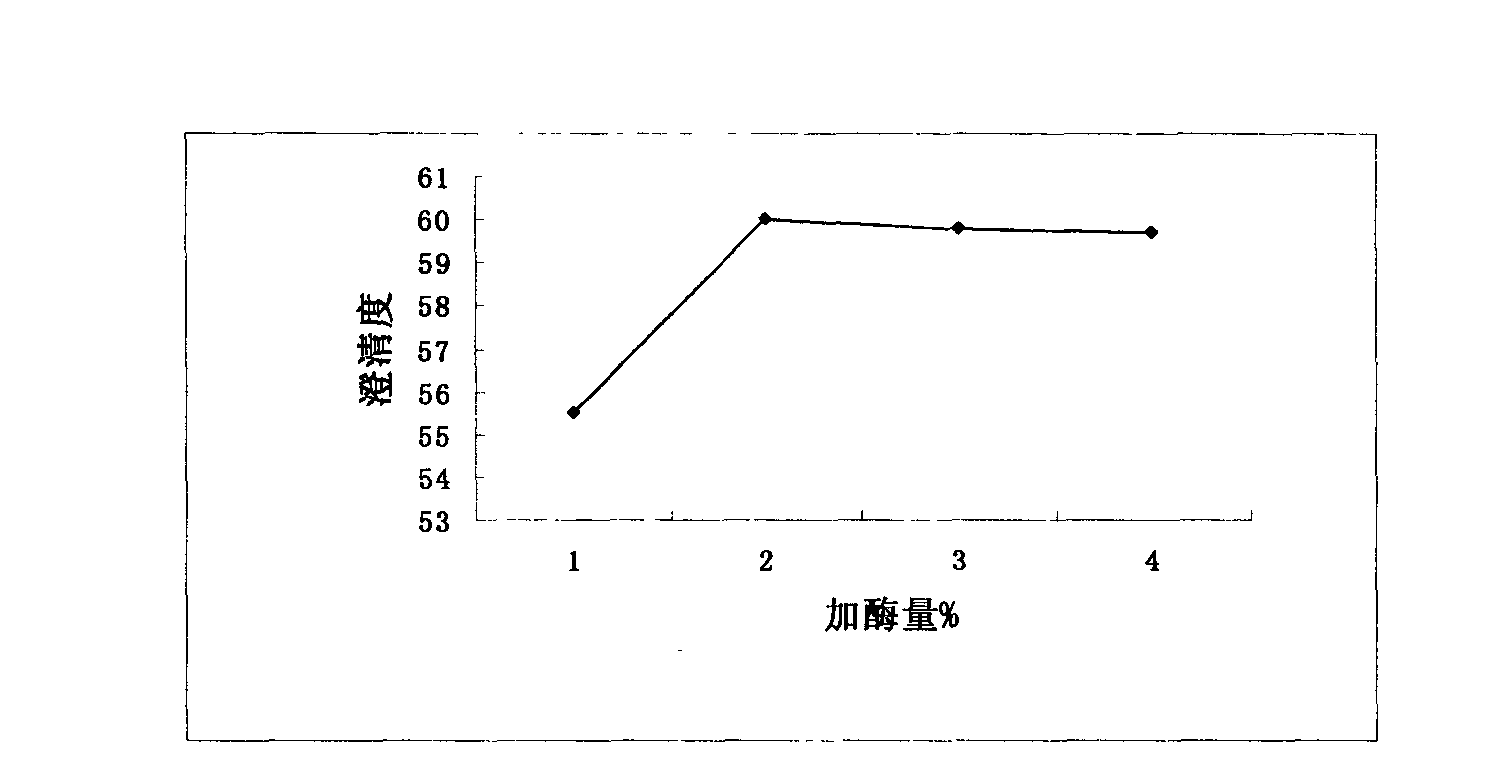

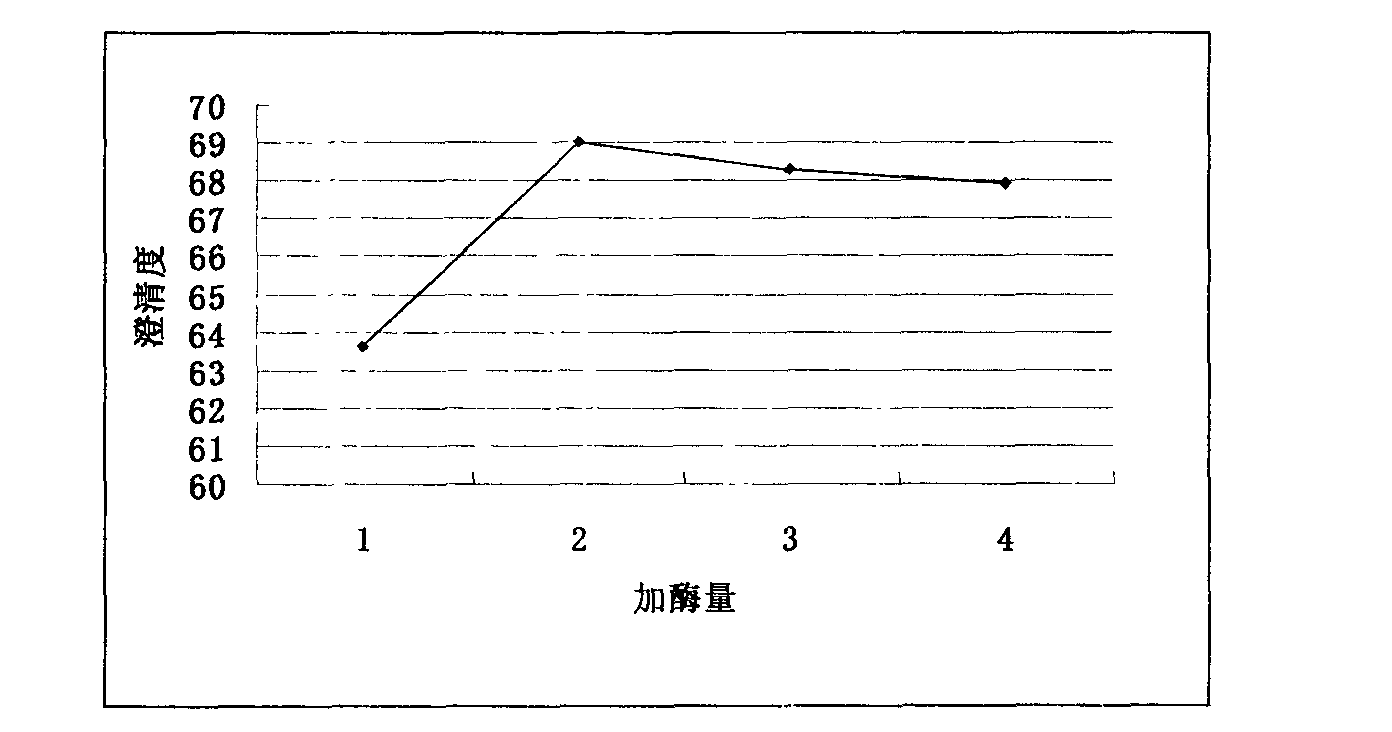

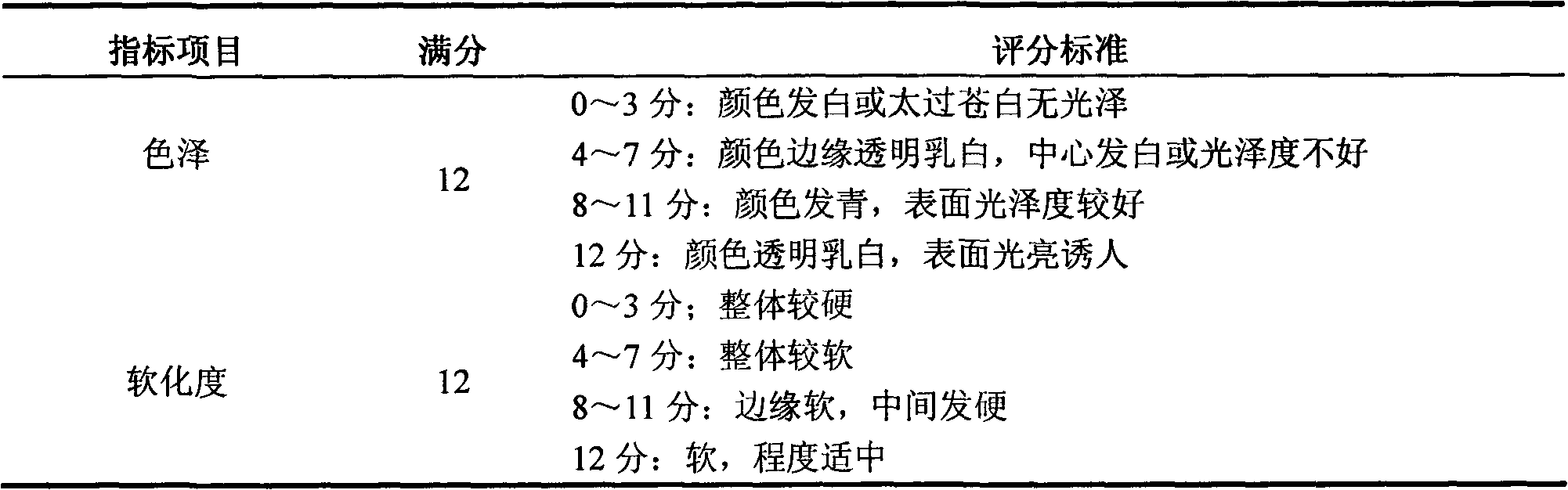

[0078] 5) Enzyme treatment Add 0.3% (lily weight) a-amylase to the gelatinized liquid, treat it at 70°C fo...

Embodiment 2

[0081] Embodiment 2, a method for enzymatic clarification of lily juice, comprising the following steps,

[0082] 1) Check and select fresh lily balls that are free of impurities, mildew, and insect eyes, and separate the lily balls to remove impurities.

[0083] 2) Hot blanching and color protection Take treated water 25 times the weight of lily balls, add color protection agent, heat to 100°C, pour in lily ball petals, and blanch for 1.5 minutes. Lily color protection conditions are: sodium chloride 0.1g / kg, citric acid 0.1g / kg, sodium erythorbate 0.2g / kg.

[0084] 3) After crushing and cooling, pour the color protection liquid and lily petals into the crusher for crushing.

[0085] 4) Gelatinization Put the beaten lily juice into a water bath at 85° C. for heating and gelatinization for 20 minutes. Stir continuously during gelatinization to make it completely gelatinized.

[0086] 5) Enzyme treatment Add 0.4% (lily weight) a-amylase to the gelatinized liquid, treat it at ...

Embodiment 3

[0089] Embodiment 3, a method for enzymolysis and clarification of lily juice, comprising the following steps,

[0090] 1) Check and select fresh lily balls that are free of impurities, mildew, and insect eyes, and separate the lily balls to remove impurities.

[0091] 2) Hot blanching and color protection Take treated water 20 times the weight of lily balls, add color protection agent, heat to 100°C, pour in lily ball petals, and blanch for 2 minutes. Lily color protection conditions are: sodium chloride 0.1g / kg, citric acid 0.1g / kg, sodium erythorbate 0.2g / kg.

[0092] 3) After crushing and cooling, pour the color protection liquid and lily petals into the crusher for crushing.

[0093] 4) Gelatinization Put the beaten lily juice into a water bath at 85° C. for heating and gelatinization for 20 minutes. Stir continuously during gelatinization to make it completely gelatinized.

[0094] 5) Enzyme treatment Add 0.2% (lily weight) a-amylase to the gelatinized liquid, treat it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com