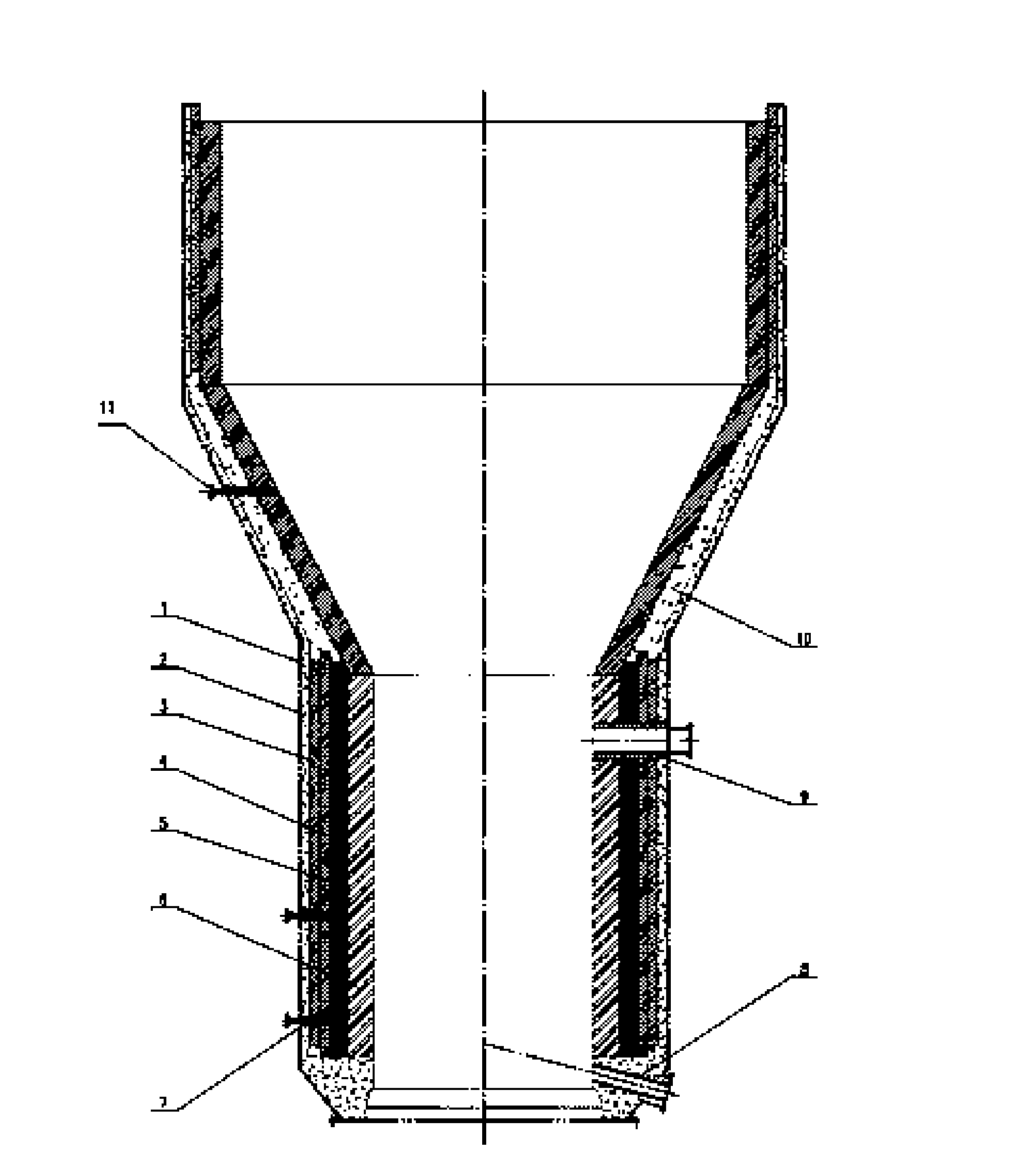

Lining structure of boiling chlorination furnace

A fluidized chlorination furnace and lining technology, applied in fluidized bed furnaces, furnaces, titanium halides, etc., can solve the problems of fluidization quality differences, threats to the life safety of operators, shortened service life, etc., and achieve product quality and The effects of capacity guarantee, low operation and maintenance costs, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: The lower part of the fluidized chlorination furnace is a cylindrical boiling section, the middle part is a conical transition section, and the upper part is a cylindrical expansion section. Acid-resistant coating 1 (diabase acid-resistant coating can be used as the material) is 5mm thick, and is evenly painted on the inner wall of the metal shell, as well as all metal surfaces such as ribs and steel pipes that appear on the inner wall, and is painted several times. Brushing should be continuous and complete.

[0018] The acid-resistant castable layer 2 is adjacent to the inner side of the acid-resistant coating 1. The thickness of the lower boiling section of the acid-resistant castable layer 2 is 100mm, the thickness of the middle transition section is 80mm, and the thickness of the upper expansion section is 60mm. bake.

[0019] The heat insulation layer is located inside the acid-resistant castable layer 2, which includes the heat insulation brick lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com