Method for realizing continuous gluing of semiconductor wafer and purification system thereof

A purification system and semi-conductor technology, which is applied to the surface coating liquid device, coating, photoplate making process coating equipment, etc., can solve the problems of blocking and polluting the purification room, so as to reduce the workload and save costs , work smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

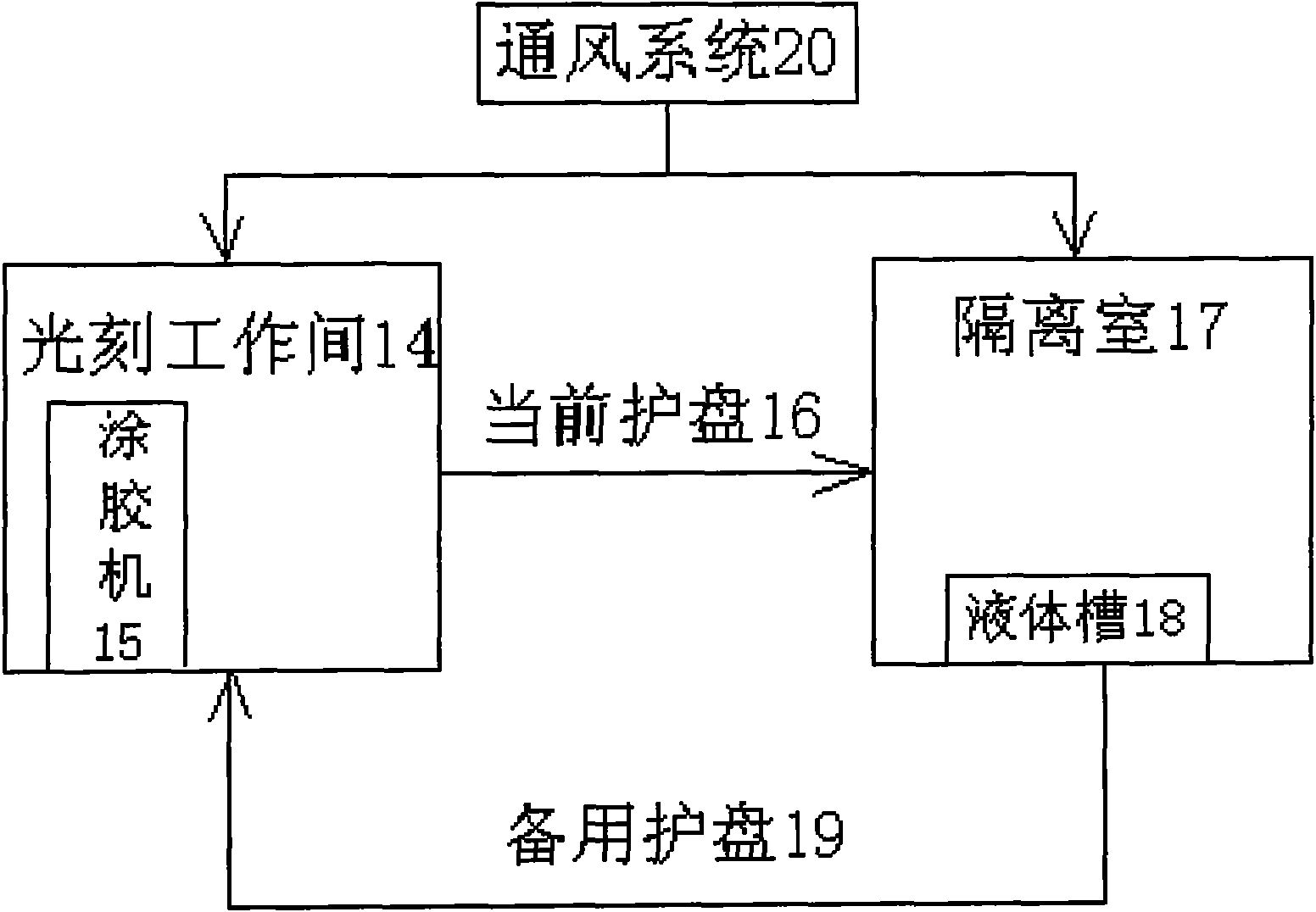

[0033] The invention provides a purification system for realizing continuous coating of semiconductor wafers. For its structural principle, see image 3 . The purification system includes a photolithography booth 14 , a glue applicator 15 , a ventilation system 20 , an isolation chamber 17 , a liquid tank 18 and a spare protection plate 19 . Wherein the ventilation site is the isolation room 17, of course the ventilation site can also be an outdoor natural environment.

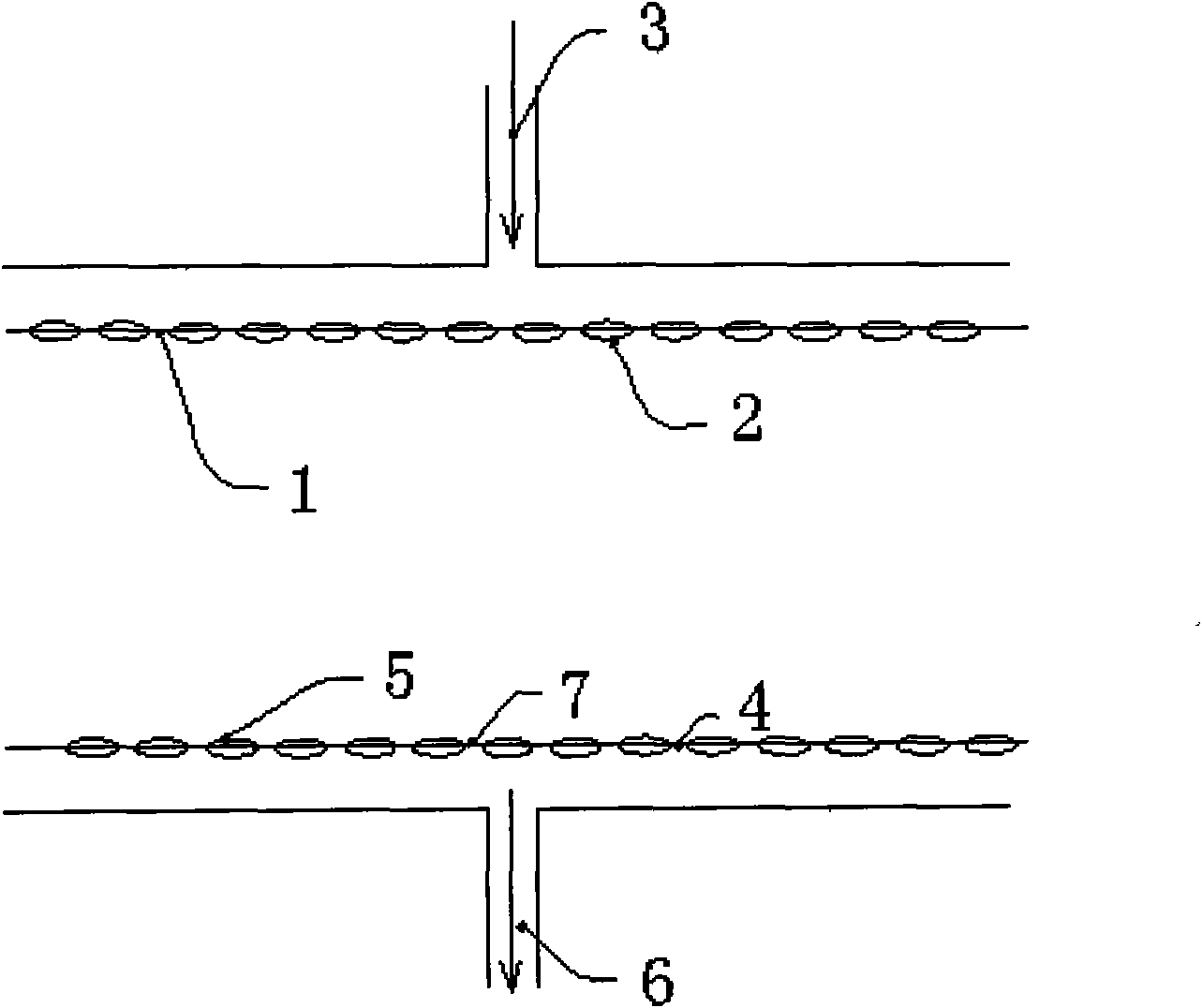

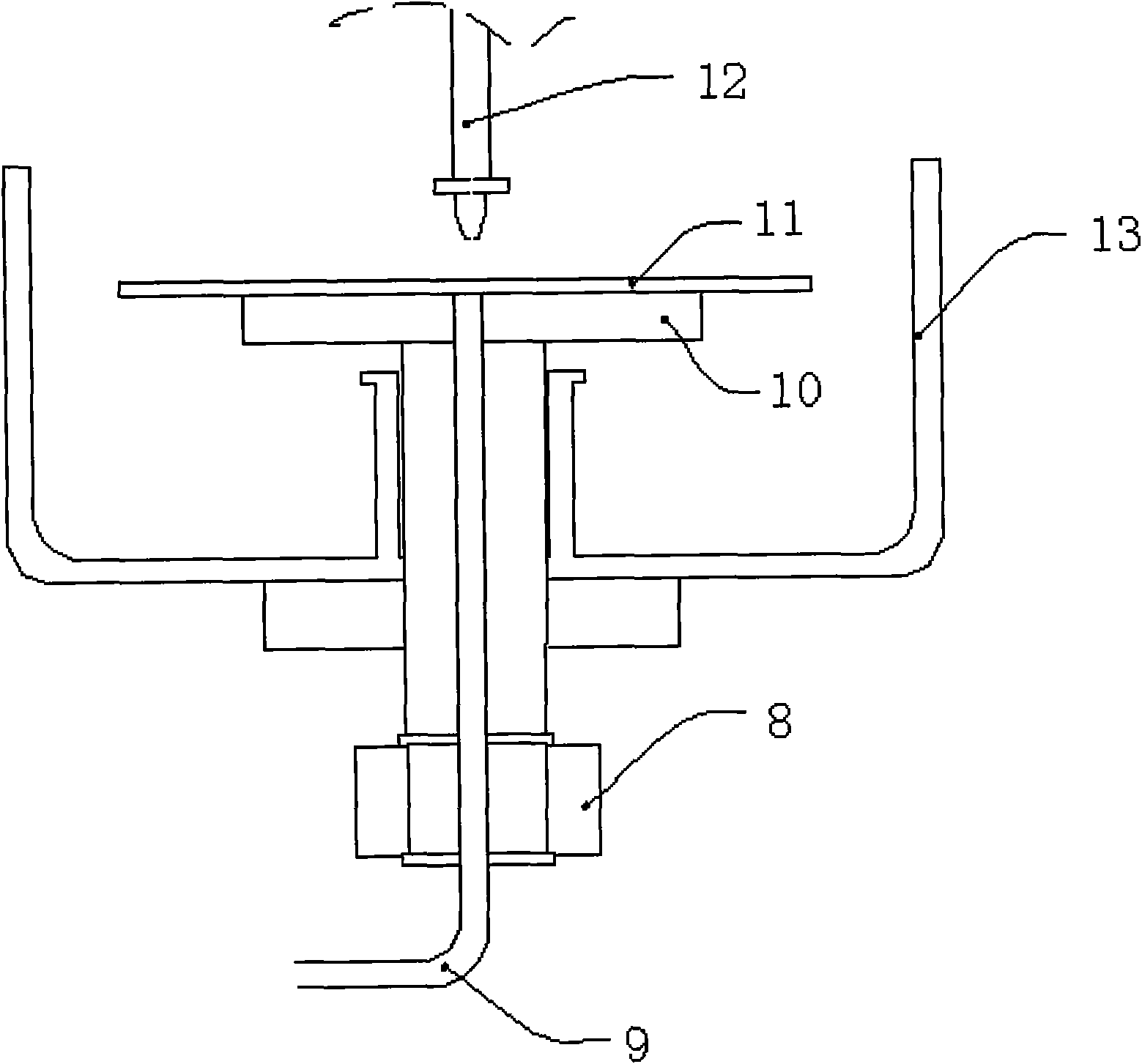

[0034] The glue applicator 15 is placed on the grid-shaped anti-corrosion floor in the photolithography workshop 14 . The gluing machine includes a current backing plate (that is, a backing plate to be cleaned on the gluing machine) 16 . The current protection plate 16 is sent into the liquid tank 18 in the isolation chamber 17 for soaking. After a period of time, take out the current backing plate 16 and dry it, make the organic solvent on the top of the backing plate volatilize and take it back to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com